Antibacterial steel plate paint baking device

A technology of baking varnish and steel plate, which is applied to the device for coating liquid on the surface, transportation and packaging, and filtration of dispersed particles, etc. It can solve the problems of unsafe use and achieve the effects of short time consumption, accelerated cooling, and convenient feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention in conjunction with the accompanying drawings in the embodiments of the present invention;

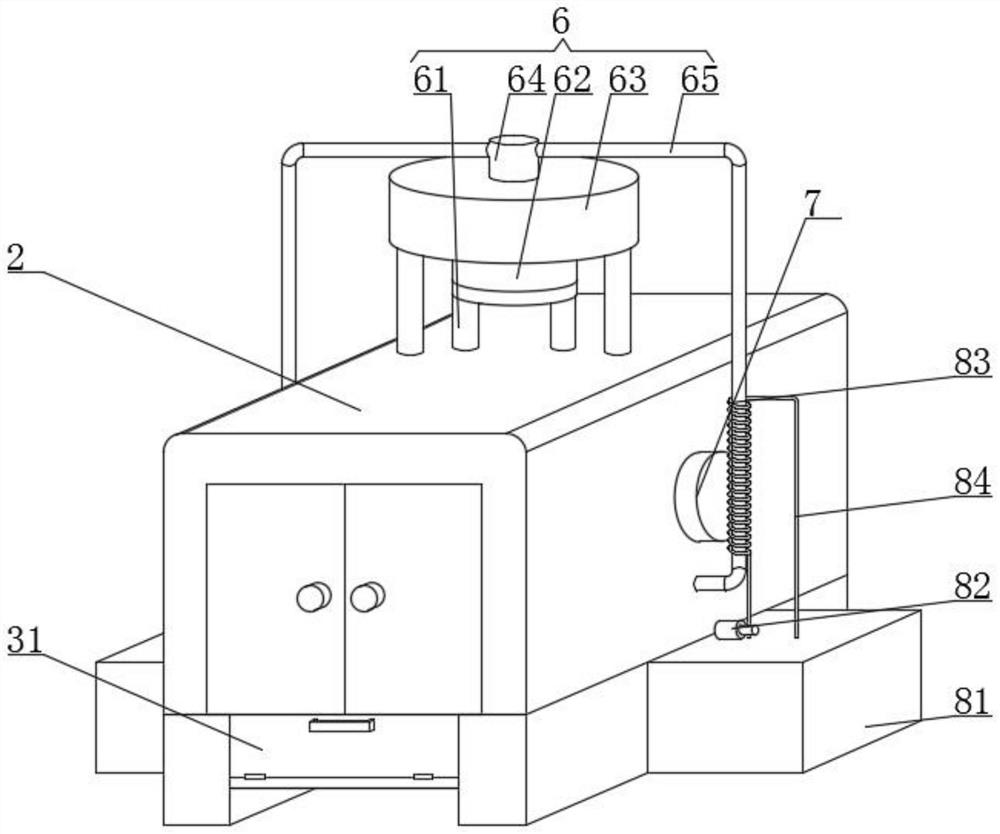

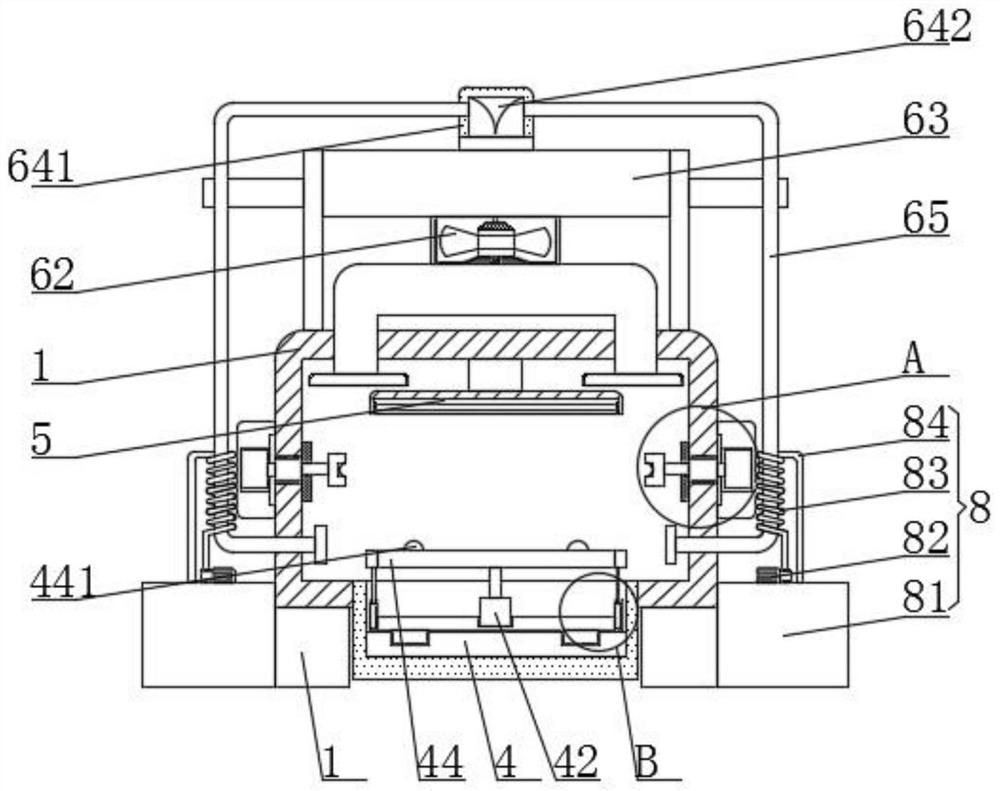

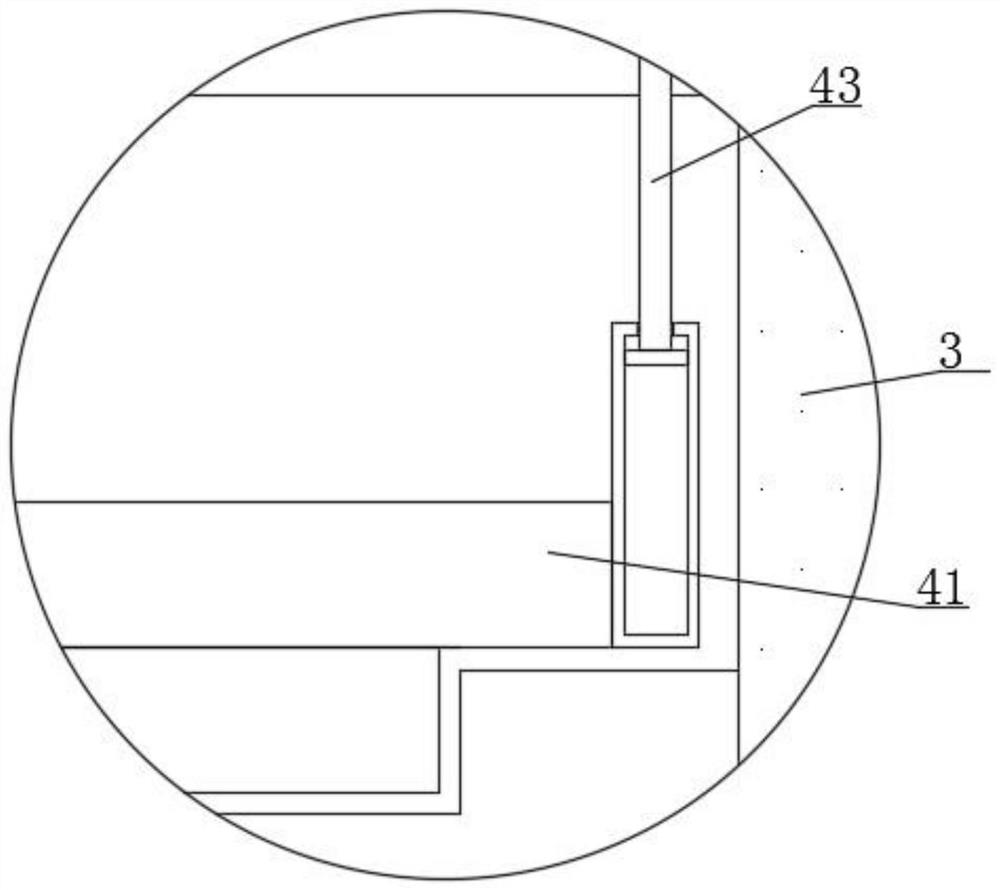

[0027] see Figure 1~6 , in the present invention, a kind of antibacterial steel plate paint baking device comprises base 1, and the top of base 1 is fixedly connected with box body 2, and the bottom of box body 2 is fixedly connected with track 3, and the top of track 3 is equipped with feeding mechanism 4, box The inside of the body 2 is fixedly connected with a baking lamp 5, the top of the box body 2 is fixedly connected with an air purification mechanism 6, two rotating mechanisms 7 are installed inside the box body 2, and cooling mechanisms 8 are installed on the left and right sides of the base 1 , Two cooling mechanisms 8 are matched with the air cleaning mechanism 6 .

[0028] In the present invention, the device is supported and fixed by the base 1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com