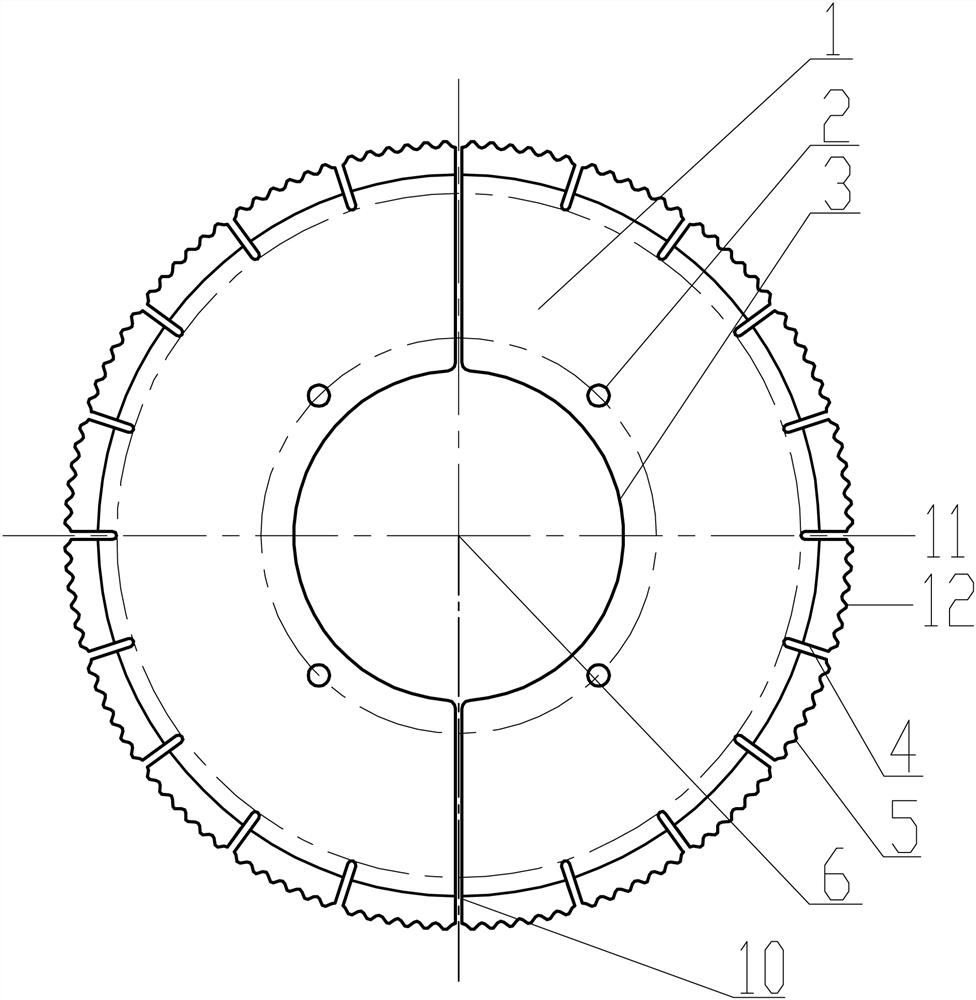

Semi-arc sintered saw blade base body and machining process

A semi-circular arc and arc saw blade technology is applied in the field of semi-circular arc sintered saw blade substrate and processing technology, which can solve the problems of insufficient processing deformation, high pressing mold and processing cost, etc., and achieves fast final shape forming and improvement. Abrasive holding force and the effect of increasing the chip space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

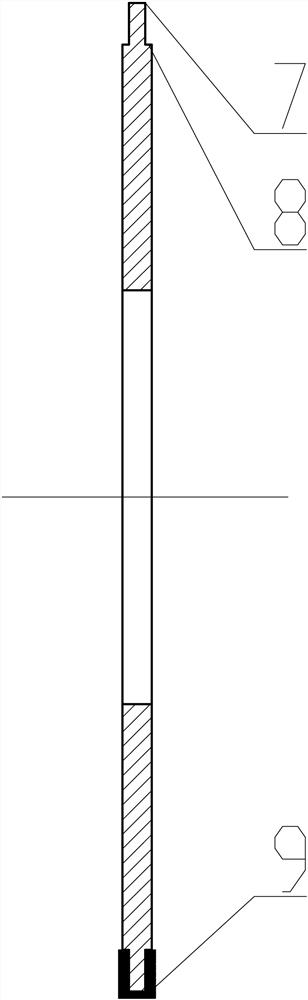

[0056] In the present invention, the processing technology of the semi-circular arc sintered saw blade base comprises the following steps:

[0057] Step 1, laser cutting and blanking: use laser cutting to cut and blank the semi-circular saw blade base 1 to a circle of φ312, and form a base disc;

[0058] Step 2, coarse grinding: Use concentric circular plane round table grinder to finely process both sides of the base disc, if the material is deformed, apply grinding and leveling to a thickness of E: 3.97;

[0059] Step 3, second calibration: finely level the double-sided planes of the base circular plate with the thickness ground to the size to the double-sided flatness ≤ 0.15, the double-sided end jump ≤ 0.15, the internal stress value is biased but not too large can;

[0060] Step 4, fine reaming: finely ream the base circular plate that has passed the leveling process to the center hole of φ25.4 in conventional applications through high-precision vertical drilling. The a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com