Heavy truck cab heating device adopting graphene heating film and heavy truck

A technology of ene heating film and heating device, which is applied in heating/cooling equipment, vehicle parts, transportation and packaging, etc., can solve the problems of not being seen, and achieve the effects of low power consumption, fast heating efficiency and short response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

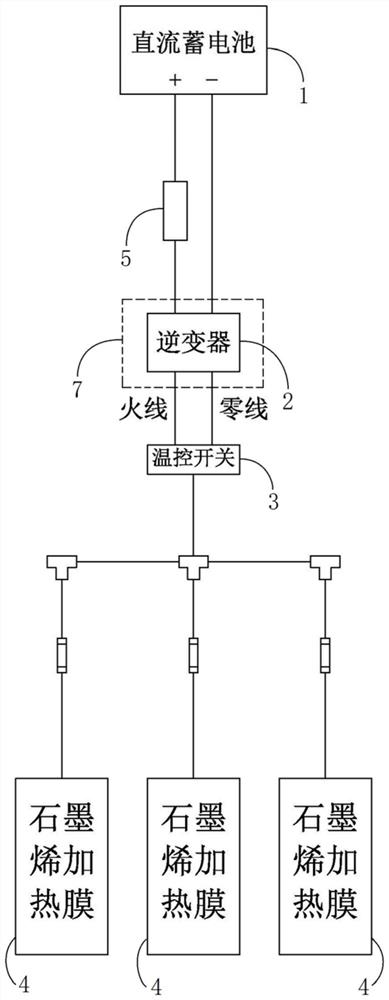

[0031] figure 1 It is a schematic diagram of the circuit principle of the heavy truck cab heating device using the graphene heating film provided by the embodiment of the present invention. Please refer to figure 1 The heavy truck cab heating device using graphene heating film provided by the embodiment of the present invention includes a DC battery 1, an inverter 2, a switch 3 and a graphene heating film 4; the DC battery 1 is electrically connected to an inverter 2 , the output end of the inverter 2 is electrically connected to the switch 3, the output end of the switch 3 is electrically connected to a plurality of graphene heating films 4, and the plurality of graphene heating films 4 are connected in parallel. Specifically, the DC battery 1 is a 24V DC battery, the inverter 2 is a 24V to 220V inverter, and the switch 3 is a temperature control switch, which controls the temperature of the graphene heating film 4 at 40°C-45°C.

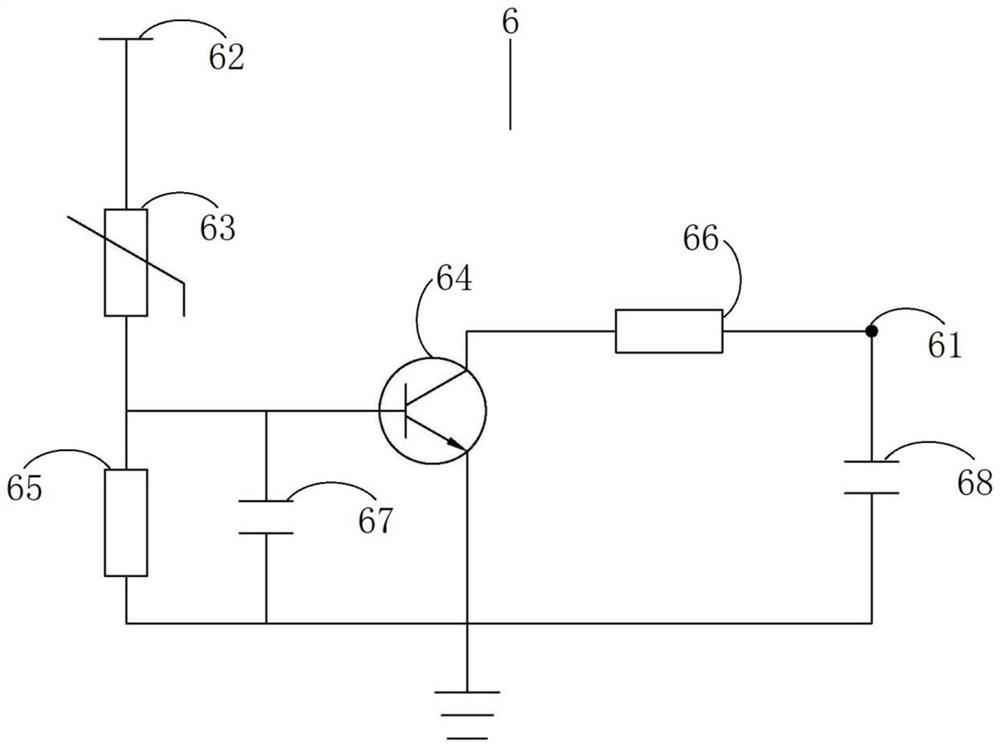

[0032] image 3 for figure 1 Schematic di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com