Redundant cooling tower for rail transit vehicle

A rail transit vehicle and cooling tower technology, which is applied in the field of rail transit, can solve the problems of high risk of rail vehicle machine failure, low integration, high noise, etc., and achieve reduced maintenance and repair time, good maintainability, low noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the object, technical solution and advantages of the present invention clearer, the technical solution of the present invention will be further specifically described through the following examples. A redundant cooling tower limit for rail transit vehicles.

[0043] In addition, in the following detailed description, for purposes of explanation, numerous specific details are set forth in order to provide a comprehensive understanding of the embodiments of the present disclosure. It may be evident, however, that one or more embodiments may be practiced without these specific details.

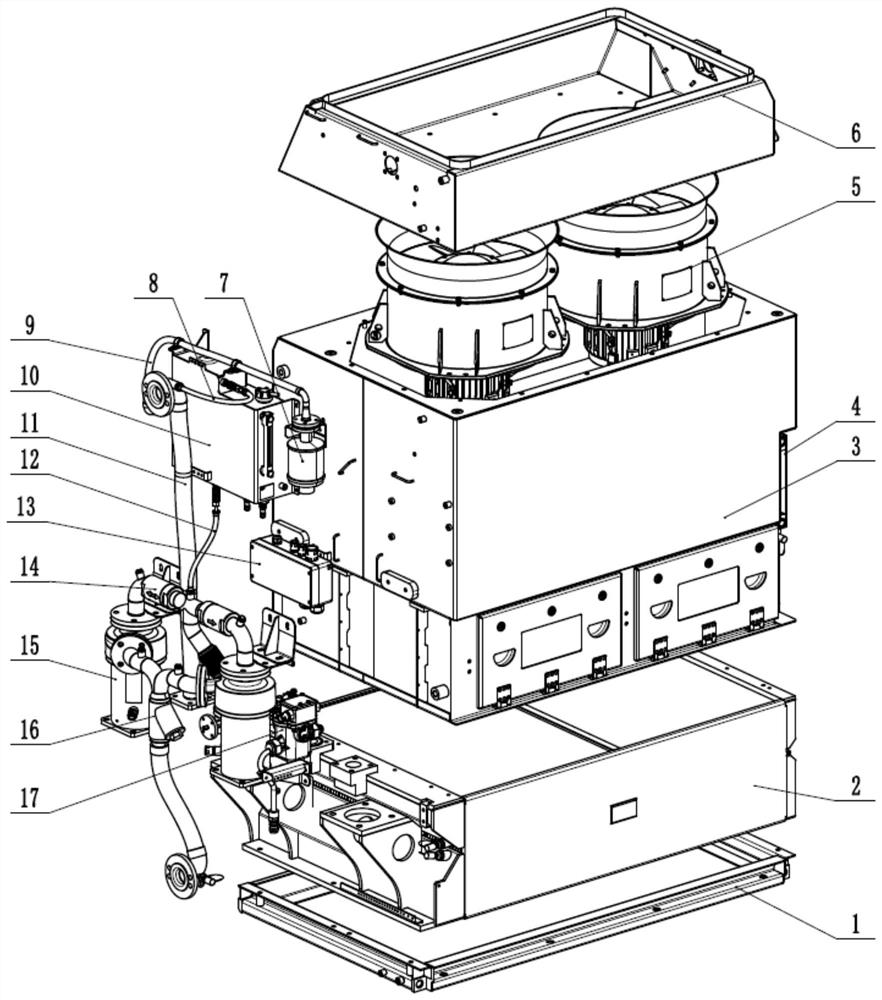

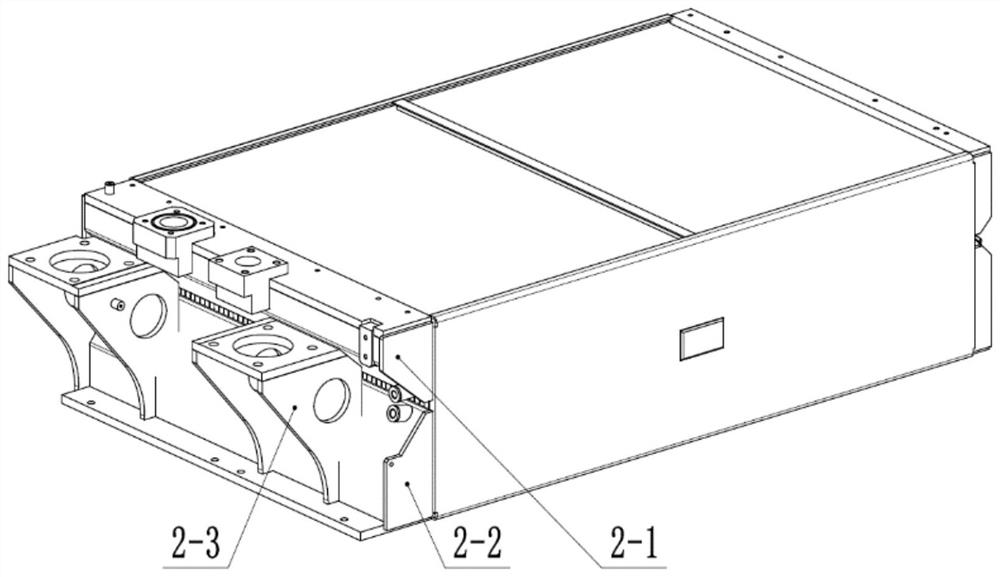

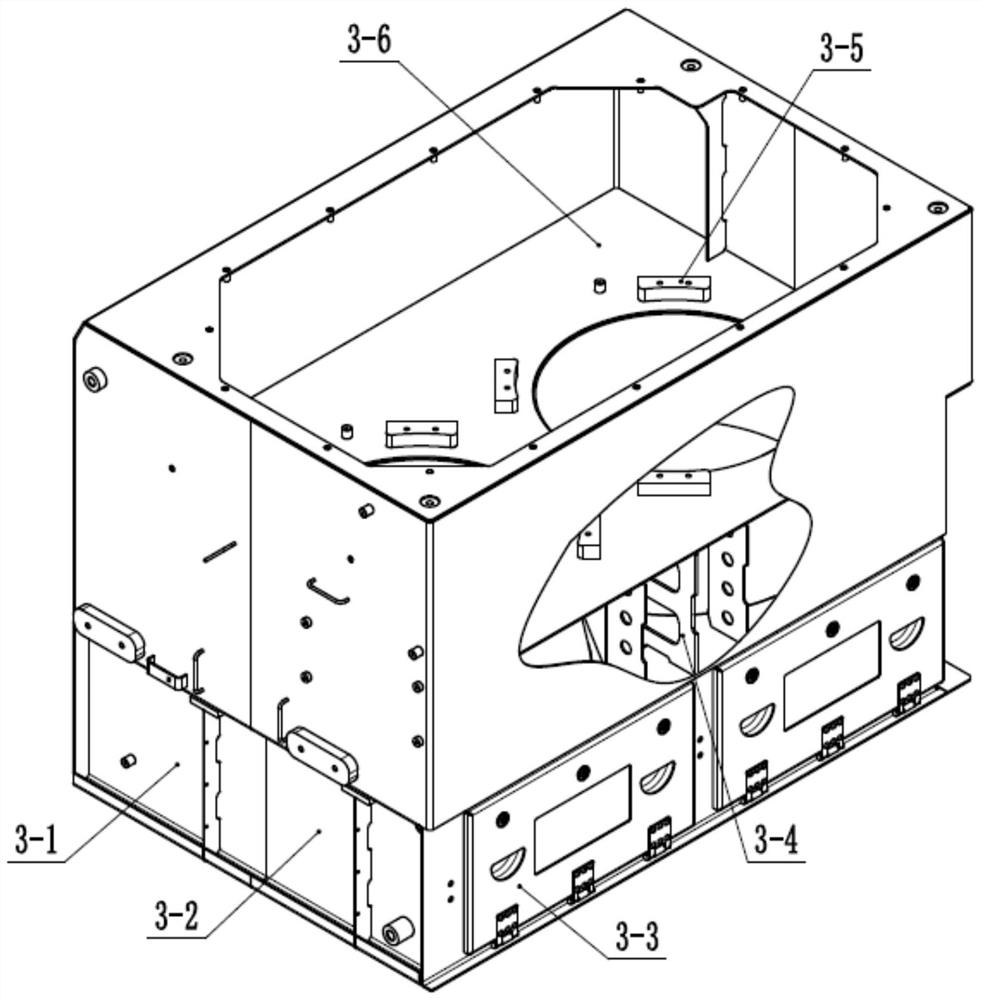

[0044] According to a general technical idea of the present invention, such as Figure 1-7 As shown, a redundant cooling tower for rail transit vehicles is provided, including an air cooling system, a converter water cooling system and a transformer oil cooling system. The air-cooling system of the cooling tower is composed of a bottom mounting base 1, a heat exchanger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com