Etching solution composition and preparation method thereof

A technology of composition and etching solution, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, circuits, etc., can solve the problems of accelerating the decomposition of hydrogen peroxide, shortening the life of etching solution, and rising the temperature of the liquid, so as to reduce decomposition and stabilize the etching rate Sex, avoid bumping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

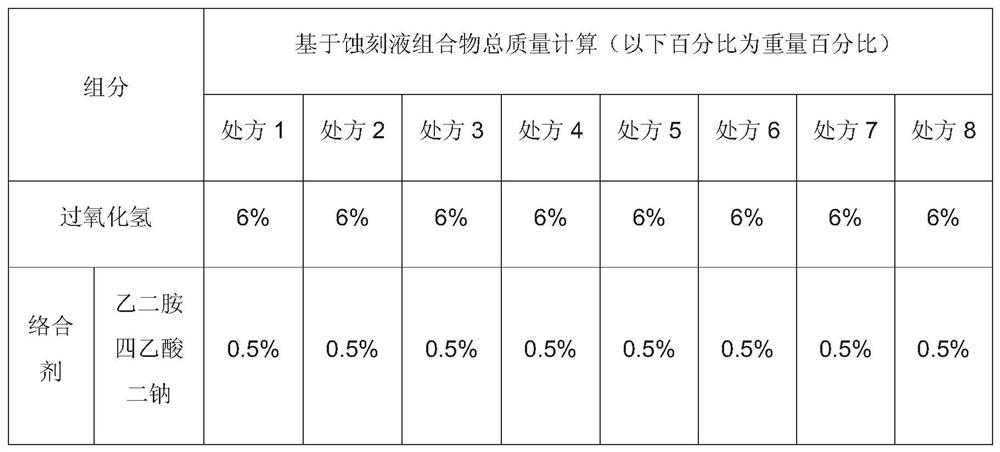

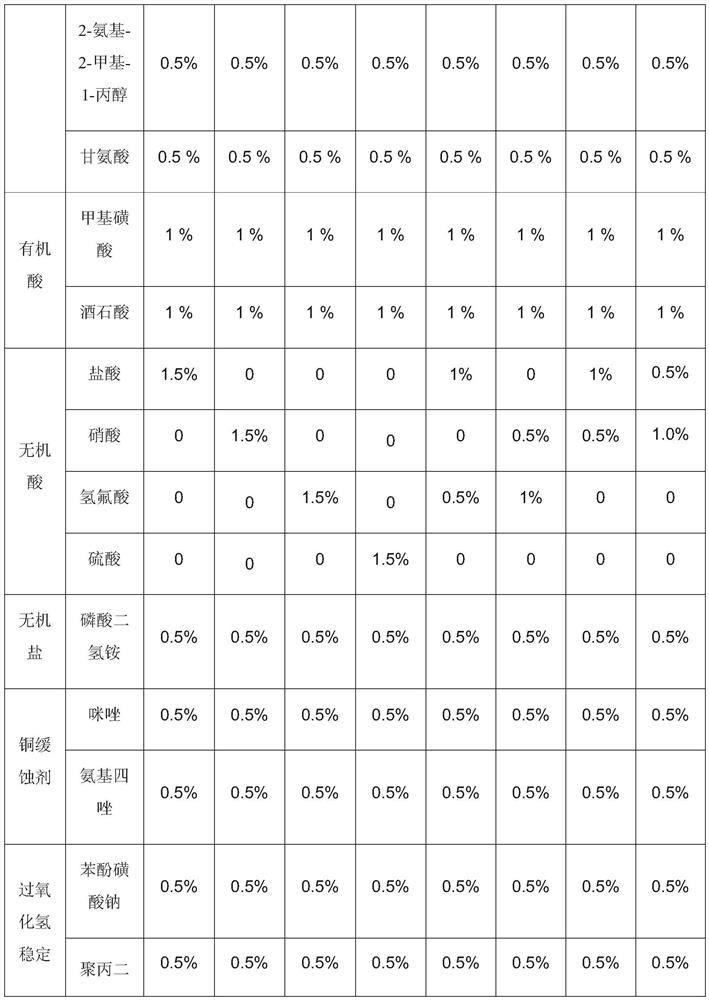

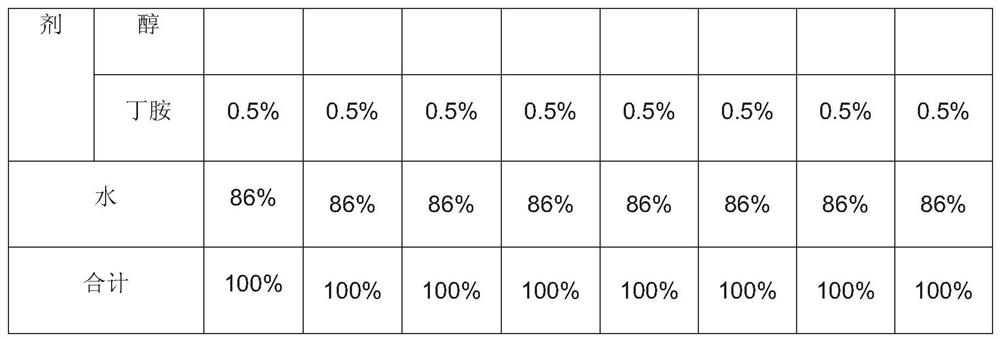

[0049] Embodiment 1: the investigation of mineral acid

[0050] Prepare the etching solution composition according to the prescription described in Table 1.

[0051] Table 1: Screening of Inorganic Acids

[0052]

[0053]

[0054]

Embodiment 2

[0055] Embodiment 2: the investigation of organic acid

[0056] Prepare the etching solution composition according to the prescription described in Table 2.

[0057] Table 2: Screening of Organic Acids

[0058]

[0059]

Embodiment 3

[0060] Embodiment 3: the investigation of complexing agent

[0061] Prepare the etching solution composition according to the prescription described in Table 3.

[0062] Table 3: Screening of Complexing Agents

[0063]

[0064]

[0065]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com