Side slope ecological restoration method based on coal gangue hydrophobic slope protection bricks

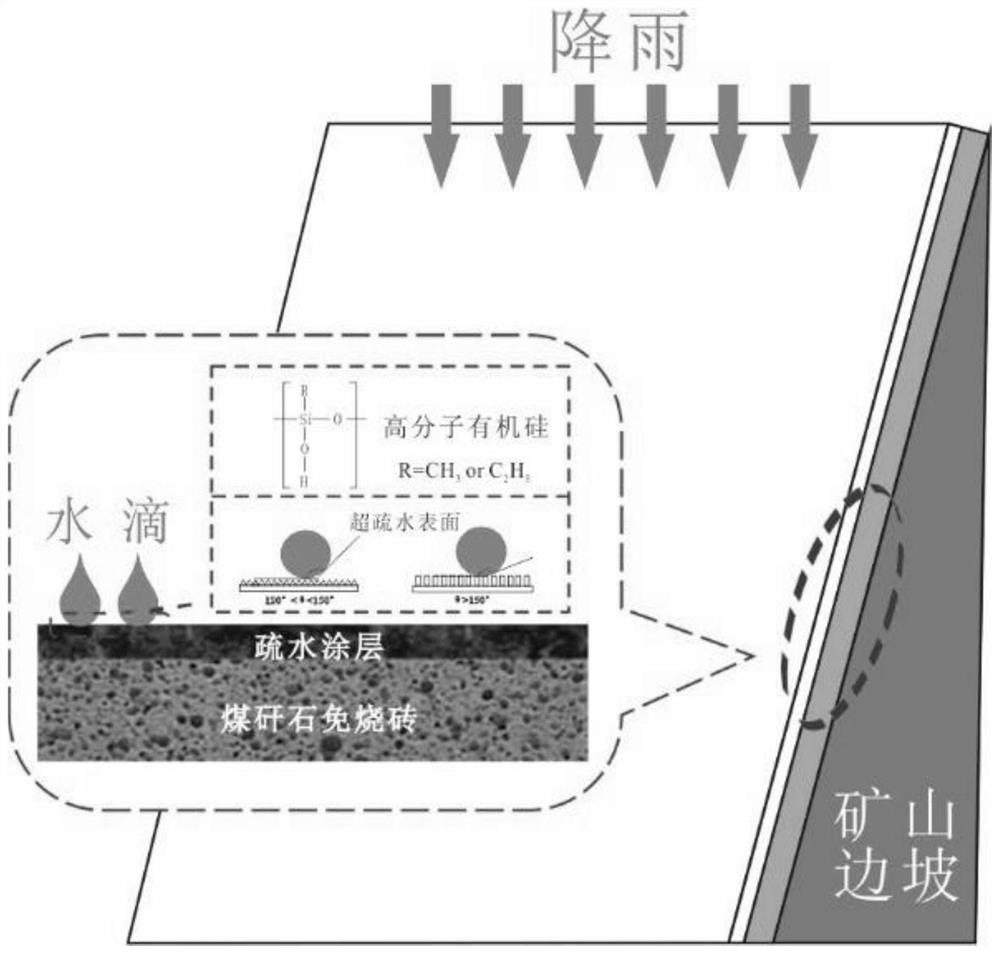

A technology of ecological restoration and slope protection bricks, applied in excavation, coastline protection, infrastructure engineering, etc., can solve the problems of easy falling off of the substrate, weak erosion resistance, and difficulty in building a comprehensive system of substrate vegetation, so as to reduce seepage and ensure survival rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

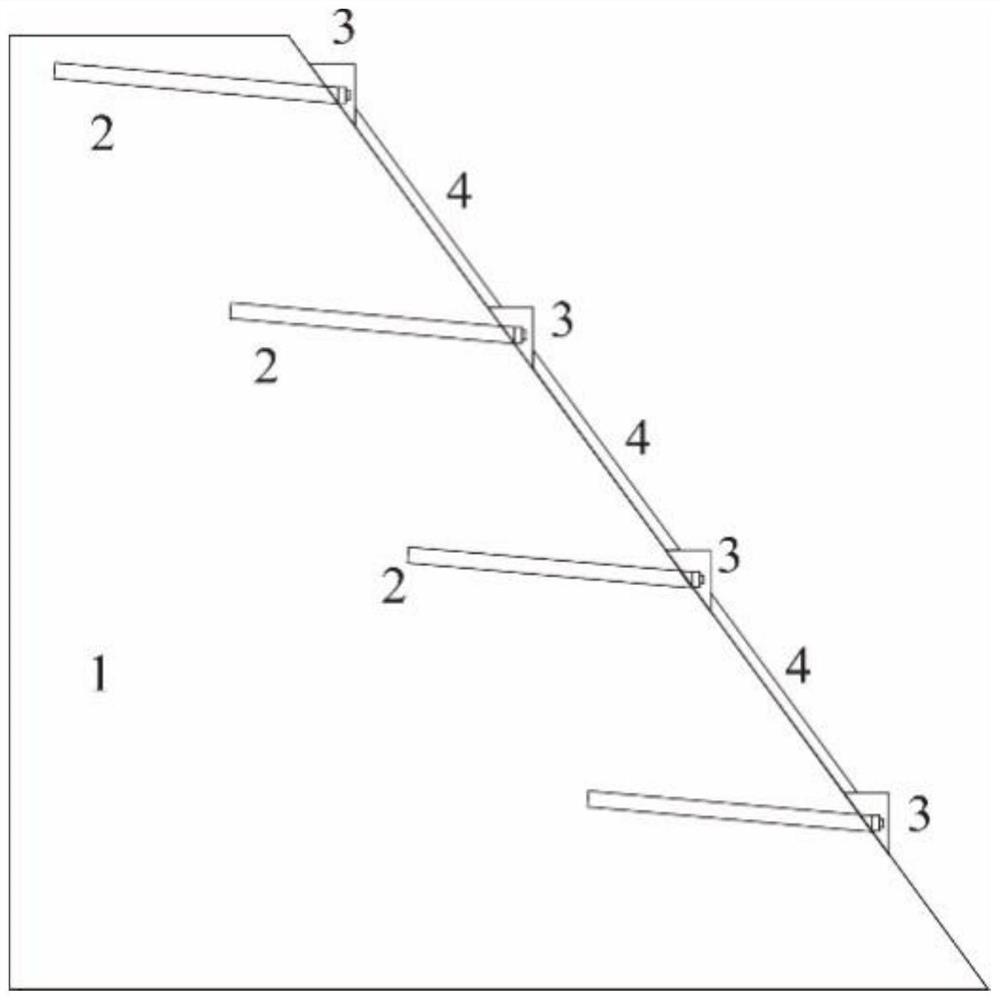

[0034] A slope ecological restoration method based on coal gangue hydrophobic slope protection bricks, comprising the following steps:

[0035] S1. Level the slope of the mine slope, and remove large protruding rocks mechanically or manually;

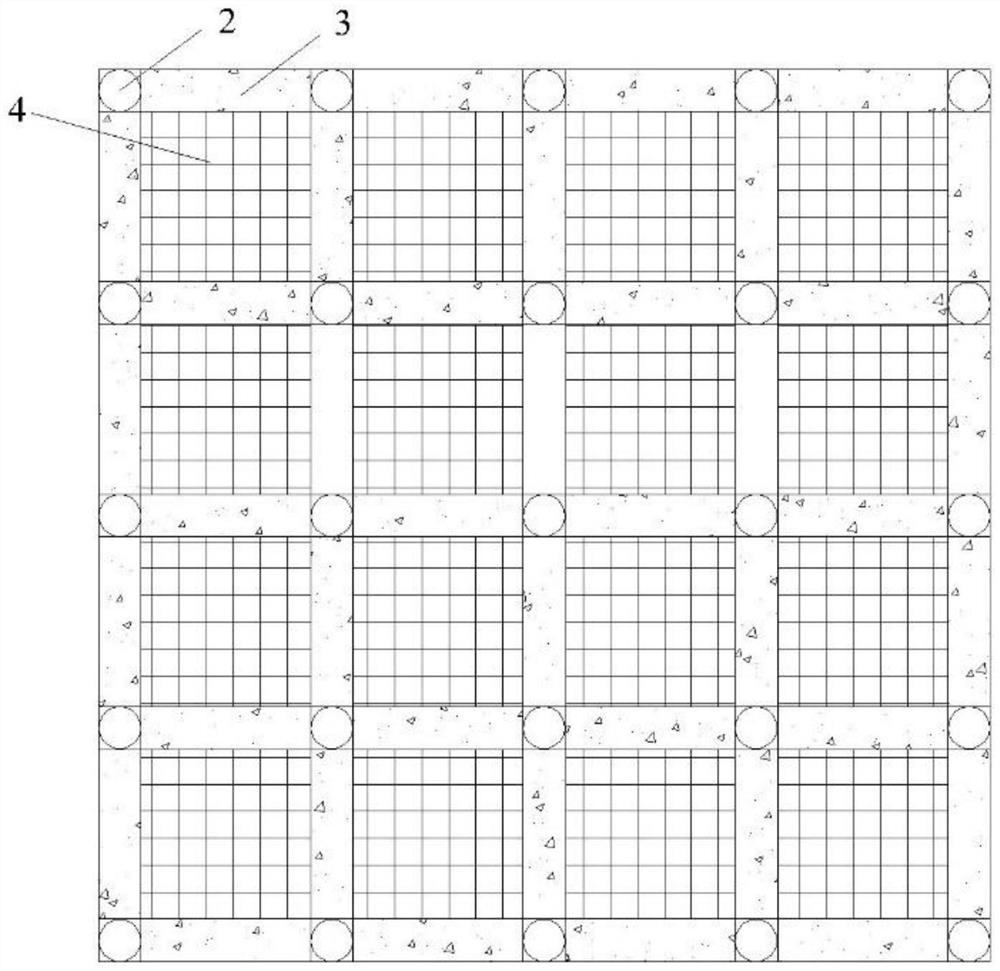

[0036] S2. Reinforce the slope of the mining area to be treated, and arrange concrete lattice on the slope to stabilize the slope. The cross-sectional size of the lattice beam is 0.4m×0.4m, using C30 concrete cast-in-situ, and the main reinforcement of the lattice is 10φ20HRB400. The plane spacing is 100mm, the top view spacing is 150mm, the thickness of the steel bar cover is 50mm, the internal and external stirrups are φ8HPB300, and the spacing is 150mm. Single-sided lap welding or binding steel bar lap joints are adopted. The lap joint length is 40 times the steel bar diameter of C30 concrete; it is carried out in the lattice structure The prestressed anchor cable is stable, linking the lattice structure and the mine as a whole to en...

Embodiment 2

[0045] The difference between Example 2 and Example 1 is that the slope protection brick is made of the following raw materials by mass fraction: 55% coal gangue, 27% natural sand, 5.14% fly ash, and 12.86% cement.

Embodiment 3

[0047] The difference between Example 3 and Example 1 is that the slope protection brick is made of the following raw materials in terms of mass fraction: 70% coal gangue, 12% natural sand, 5.14% fly ash, and 12.86% cement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com