Energy-saving building material drying device

A technology of building materials and drying equipment, which is applied in the direction of drying gas arrangement, progressive dryer, drying solid materials, etc., can solve the problems of reduced performance, incomplete drying, and low work efficiency, so as to improve adaptability and promote drying. Dry efficiency, not easy to accumulate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

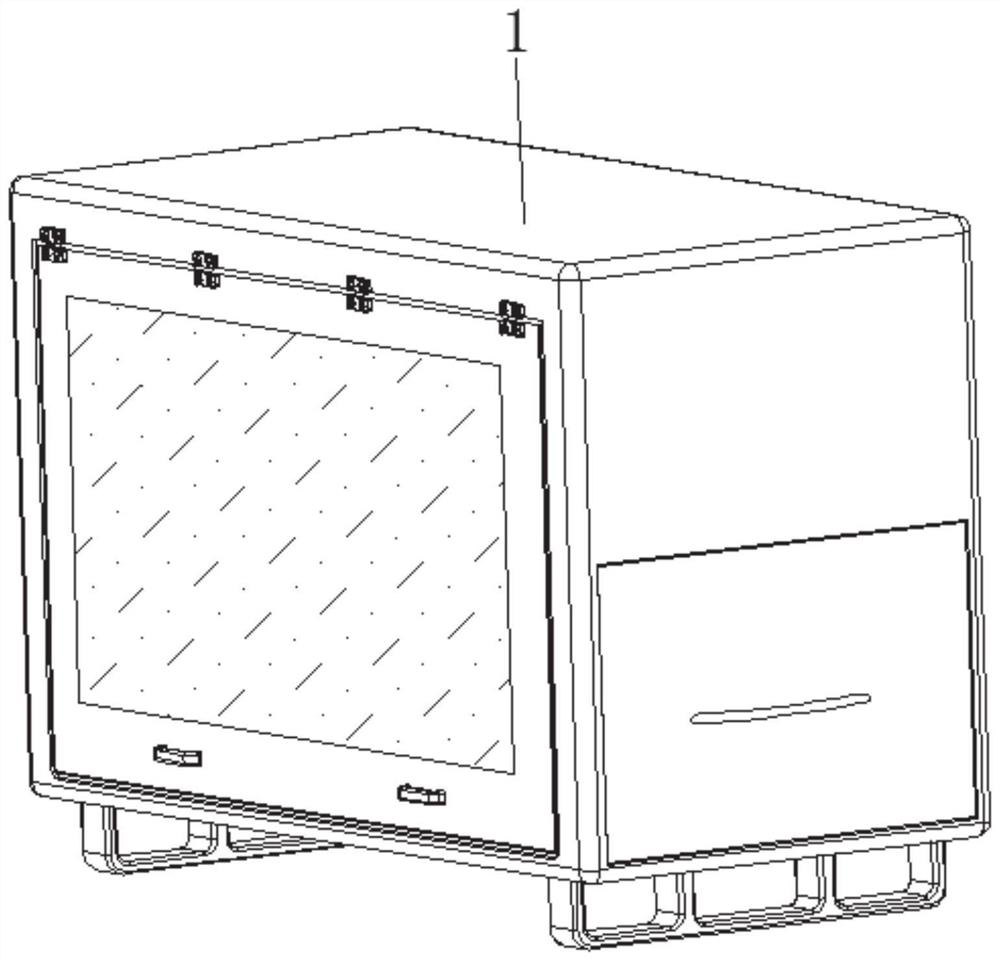

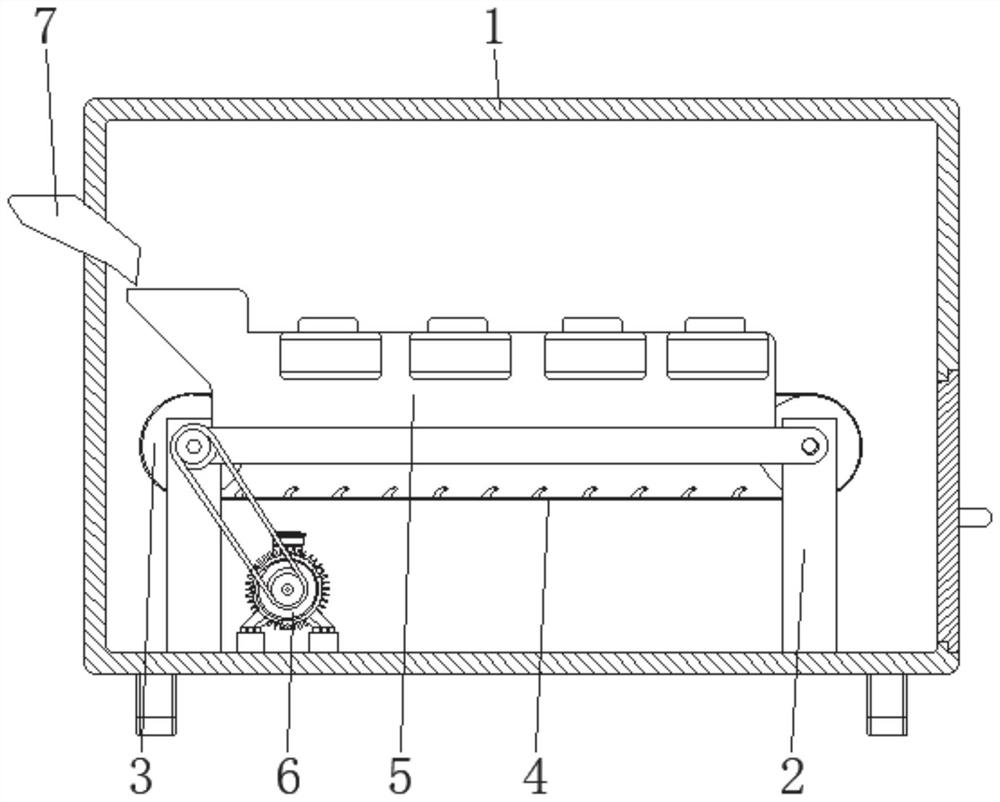

[0034] see Figure 1-7 , the present invention provides a technical solution: an energy-saving drying device for building materials, including a body 1, a bracket 2, a transmission roller 3, a conveying device 4, and a drying device 5, and the bottom of the bracket 2 is fixedly connected to the bottom of the inner wall of the body 1 , the end of the drive roller 3 is rotatably connected to the top of the support 2 and is located at the end position, the conveying device 4 is arranged on the surface of the drive roller 3, and the drying device 5 is arranged on the top of the support 2 and close to the position of the conveying device 4;

[0035] The bottom of the inner wall of the body 1 is fixedly connected with a servo motor 6, the output shaft of the servo motor 6 is connected to one end of the drive roller 3 through a belt transmission assembly, and the side of the surface of the body 1 and one end close to the drying device 5 is provided with a feed The bucket 7 uses the s...

Embodiment example 2

[0037] Conveying device 4 is provided with elastic conveying net 41, rubber edge 42, beading device 43, and elastic conveying net 41 is arranged on the surface of drive roller 3, and rubber edge 42 is arranged on the two sides corresponding to elastic conveying net 41 surface edges, and beading device 43 It is arranged on the inner wall of the elastic conveying net 41 .

[0038] The elastic conveying net 41 is set as a closed loop, the rubber edge 42 is set as a closed loop, and the pressing device 43 is evenly distributed on the inner wall of the elastic conveying net 41 .

[0039] Beading device 43 is provided with beading main body 431, ball 432, and one end of beading main body 431 is fixedly connected with the inwall of elastic conveying network 41, and the surface of beading main body 431 is set as arc surface, and ball 432 is rollingly connected on the surface of beading main body 431, utilizes The rotation of the transmission roller 3 drives the elastic conveying net 4...

Embodiment example 3

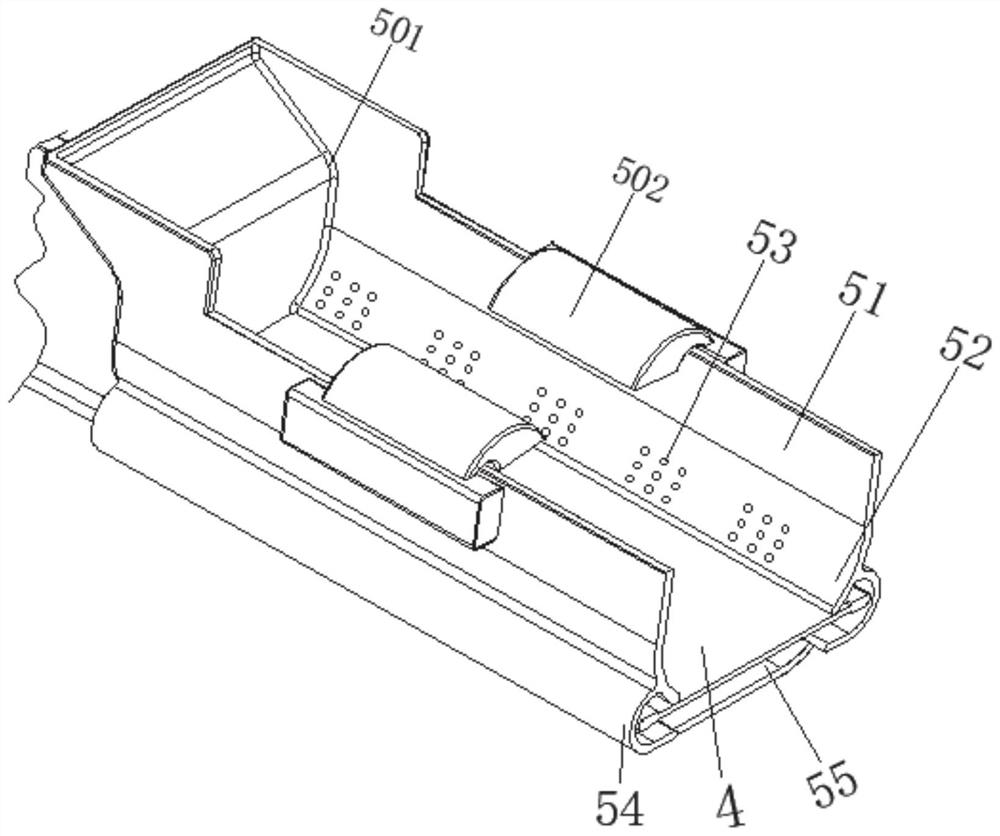

[0041] The drying device 5 is provided with a side plate 51, an arc-shaped inner concave surface 52, an air injection hole 53, an arc-shaped housing 54, and a pressure outlet device 55. The arc-shaped inner concave surface 52 is arranged on the surface bottom of the side plate 51, and the air injection hole 53 is provided. Inside the arc-shaped concave surface 52 and at the position of the arc-shaped concave surface 52, the arc-shaped housing 54 is arranged on the bottom of the surface of the side plate 51 and on the side away from the air injection hole 53. The surface of the arc-shaped housing 54 is in contact with the bracket 2 The top is fixedly connected, and the pressurized air outlet device 55 is arranged at the bottom of the arc-shaped housing 54 and close to the position of the conveying device 4;

[0042] The pressurized air outlet device 55 is provided with a base plate 551, a pressing device 552, an elastic member 553, and an elastic air bag 554. The end of the base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com