Precious metal wire thermal regulation and control magnetic tunnel junction

A technology of magnetic tunnel junction and noble metal, which is applied in the direction of magnetic field controlled resistors, parts of electromagnetic equipment, and electric/magnetic devices to transmit sensing components, etc. The promotion and application of tunnel junctions and other issues, to achieve the effect of high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

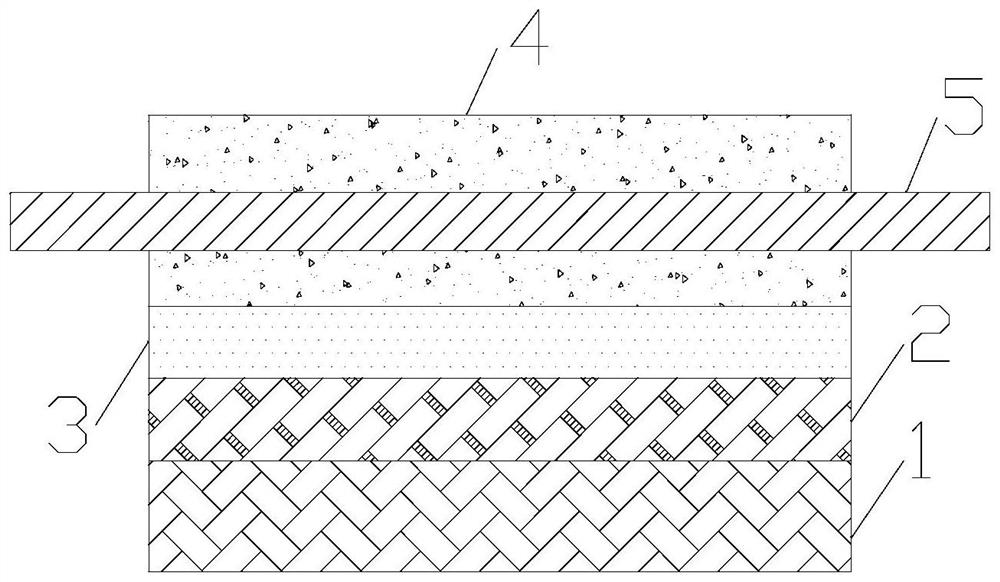

[0020] The invention provides a thermally regulated magnetic tunnel junction of noble metal wires, such as figure 1 As shown, it includes an antiferromagnetic layer 1 , a pinning layer 2 , a barrier layer 3 , a free layer 4 , and a noble metal wire 5 . The material of the antiferromagnetic layer 1 is a hard magnetic antiferromagnetic material, specifically, the material of the antiferromagnetic layer 1 is IrMn, PtMn, FeMn. The pinning layer 2 is placed on the antiferromagnetic layer 1 . The material of the pinning layer 2 is a metal or semi-metal with high spin polarizability, specifically, the material of the pinning layer 2 is Co, Fe, CoFe, CoFeB, CoFeAl alloy. The barrier layer 3 is placed on the pinning layer 2 . The material of the barrier layer 3 is aluminum oxide or magnesium oxide. The free layer 4 is placed on the barrier layer 3 . The material of the free layer 4 is soft magnetic material with weak magnetic anisotropy, specifically, the material of the free layer...

Embodiment 2

[0024] On the basis of Embodiment 1, on the barrier layer 3 side, the surface of the noble metal wire 5 is a plane. The plane is parallel to the surface of the barrier layer 3 . The distance between the plane and the surface of the barrier layer 3 is less than 1 micron. In this way, the heat in the noble metal wire 5 can be transferred to the potential barrier layer 3 more, thereby changing the temperature of the potential barrier layer 3, thereby changing the quantum tunneling characteristics of the potential barrier layer 3, thereby realizing a more sensitive magnetic tunnel junction. regulation.

Embodiment 3

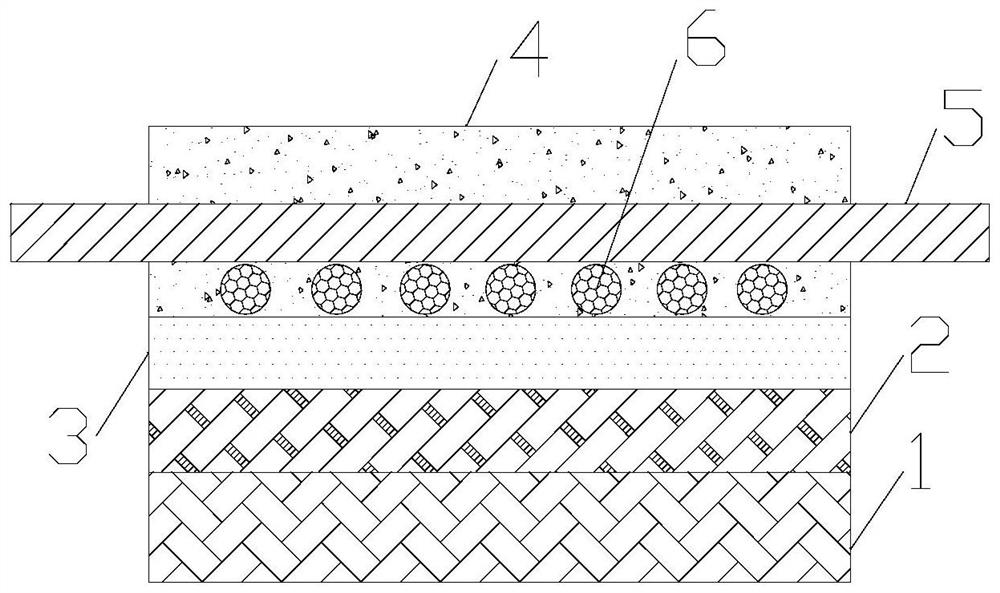

[0026] On the basis of Example 2, such as figure 2 As shown, semiconductor particles 6 are also included, and the semiconductor particles 6 are placed on the plane. The size of the semiconductor particles 6 is less than 200 nanometers. That is, noble metal wires 5 are in contact with semiconductor particles 6 . In this way, a Schottky junction is formed between the noble metal wire 5 and the semiconductor particle 6 . When the temperature of the noble metal wire 5 changes, the charge distribution on the surface of the semiconductor particle 6 is changed, thereby changing the local electric field on the surface of the barrier layer 3, thereby changing the probability of electrons passing through the barrier layer 3, thereby changing the magnetic field. The magnetoresistance of the tunnel junction is realized, thereby realizing the magnetoresistance regulation of the magnetic tunnel junction with high sensitivity.

[0027] Furthermore, the shape of the semiconductor particle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com