Adsorption type gas detector

A gas detector and adsorption technology, which is applied in the field of gas detection, can solve the problems of low detection limit and insufficient gas detection sensitivity, and achieve the effect of high gas detection sensitivity and multiple types of detection molecules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

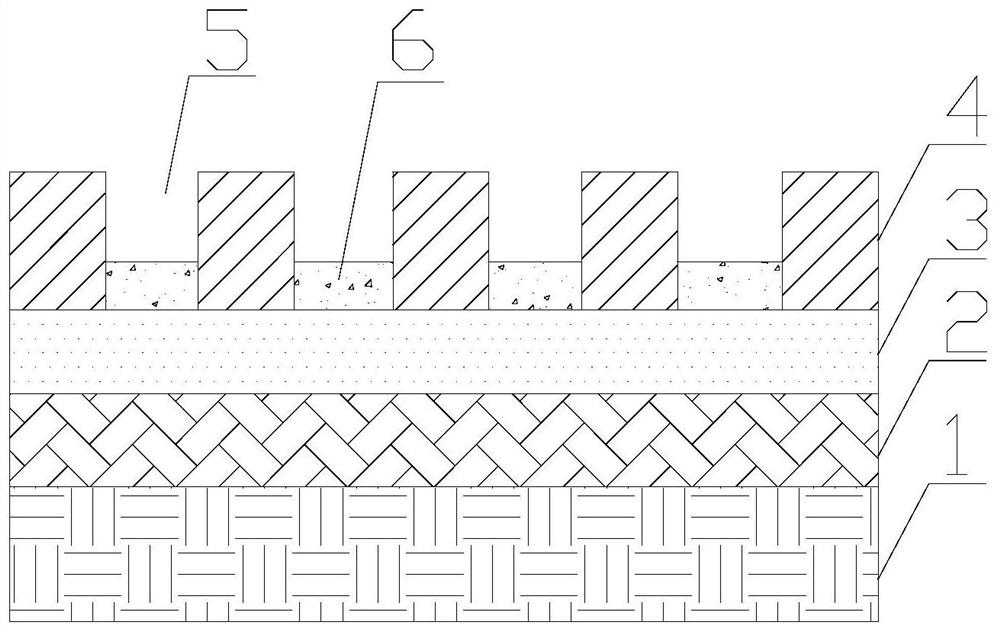

[0020] The invention provides an adsorption gas detector, such as figure 1 As shown, it includes an antiferromagnetic layer 1 , a pinning layer 2 , a barrier layer 3 , a free layer 4 , and a porous material part 6 . The material of the antiferromagnetic layer 1 is a hard magnetic antiferromagnetic material. Specifically, the material of the antiferromagnetic layer 1 is IrMn, PtMn, FeMn. The pinning layer 2 is placed on the antiferromagnetic layer 1 . The material of the pinning layer 2 is a metal or semi-metal with high spin polarizability, specifically, the material of the pinning layer 2 is Co, Fe, CoFe, CoFeB, CoFeAl alloy. The barrier layer 3 is placed on the pinning layer 2 . The material of the barrier layer 3 is aluminum oxide or magnesium oxide. The free layer 4 is placed on the barrier layer 3 . The material of the free layer 4 is soft magnetic material with weak magnetic anisotropy, specifically, the material of the free layer 4 is NiFe alloy, CoFe alloy, CoFeB ...

Embodiment 2

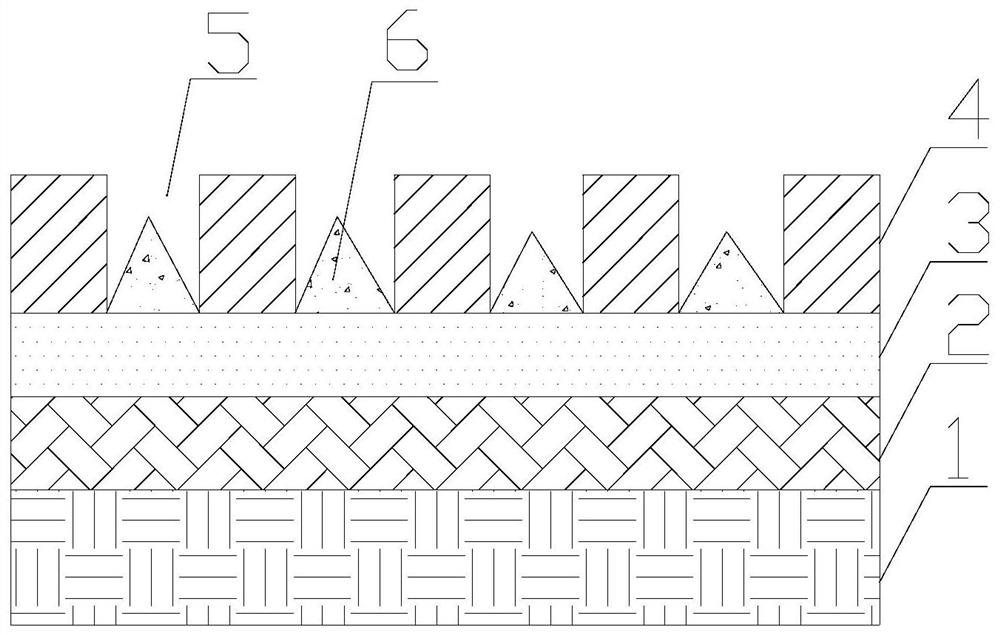

[0025] On the basis of Example 1, such as figure 2 As shown, the shape of the porous material part 6 is a pointed cone. In this way, on the one hand, the porous material portion 6 is less in contact with the sidewall of the hole 5, that is, the porous material portion 6 is less in contact with the free layer 4, so as to reduce the heat transfer generated by the porous material portion 6. To the free layer 4, the heat lost to the outside through the free layer 4 is reduced; on the other hand, the tapered porous material part 6 has more surface area, so that the porous material part 6 can absorb more gas. The effects of these two aspects are beneficial to the barrier layer 3 to absorb more heat, thereby changing the temperature of the barrier layer 3 more, thereby changing the quantum tunneling characteristics of the barrier layer 3 more, thereby changing the temperature of the barrier layer 3 more. The magnetoresistance of the magnetic tunnel junction, enabling higher sensiti...

Embodiment 3

[0027] On the basis of Embodiment 2, the porous material part 6 protrudes from the hole 5 . In this way, the porous material part 6 has more surface area and more volume, and the porous material part 6 can absorb more gas molecules, thereby generating more heat, changing its own weight more, thereby more Change the temperature of the barrier layer 3 and the stress of the barrier layer 3, thereby changing the quantum tunneling characteristics of the barrier layer 3 more, thereby changing the magnetoresistance of the magnetic tunnel junction more, thereby achieving higher sensitivity gas detection .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com