Electrolyte, manufacturing method thereof and lead-acid storage battery prepared from electrolyte

A lead-acid battery and electrolyte preparation technology, applied in lead-acid battery, lead-acid battery construction, final product manufacturing, etc., to reduce water loss, ensure cold-start life, and improve product consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

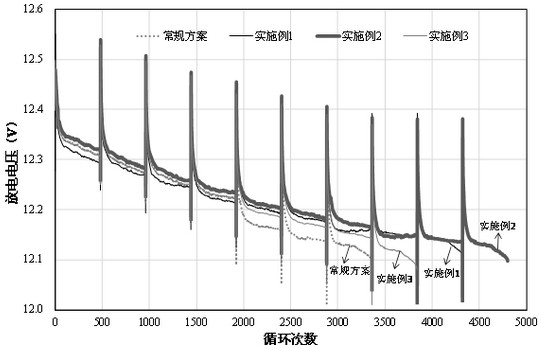

Examples

Embodiment 1

[0046] Manufacture of electrolyte:

[0047] (1) Preparation of porous silica nanoparticles: Take 2 parts by weight of cetyltrimethylammonium bromide and add 50 parts by weight of deionized water, which contains 0.5% by weight of ammonia water, cetyltrimethylammonium bromide Contain 0.5% by weight of triethanolamine in methyl ammonium bromide, heat to 75°C, continue stirring at a constant temperature for 60 minutes, then drop in 5 parts by weight of ethyl orthosilicate at a constant speed, control the time at about 10 minutes, and continue stirring at a constant temperature for 4 hours Finally, take it out and separate it with a centrifuge at 10,000 rpm for 10 minutes to obtain a white solid, dry it in a vacuum at 80°C for more than 12 hours, and then place it in a muffle furnace for calcination at 300°C for 10 hours to obtain porous silica nanoparticles. The size of silicon oxide nano-ions is between 100-200nm, and the pore size is 5-8nm;

[0048] (2) Prepare a solution conta...

Embodiment 2

[0058] Manufacture of electrolyte:

[0059] (1) Preparation of porous silica nanoparticles: Take 3 parts by weight of the structure-directing agent cetyltrimethylammonium bromide and add it to 100 parts by weight of deionized water, which contains 1% by weight of sodium hydroxide, Hexadecyltrimethylammonium bromide contains 5% by weight of triethanolamine, heat it to 60°C, continue to stir at constant temperature for 45 minutes, then drop in 6 parts by weight of tetraethyl orthosilicate at a constant speed, control the time at about 10 minutes, continue After stirring and reacting at constant temperature for 3 hours, take it out and separate it with a centrifuge at 10,000 rpm for 10 minutes to obtain a white solid, dry it in vacuum at 80°C for more than 12 hours, and then place it in a muffle furnace for calcination at 300°C for 10 hours to obtain porous silica Nano-ion, the size of porous silica nano-ion is between 50-100nm, and the pore size is 3-6nm;

[0060] (2) The prepa...

Embodiment 3

[0070] Manufacture of electrolyte:

[0071](1) Preparation of porous silica nanoparticles: Take 4 parts by weight of the structure-directing agent cetyltrimethylammonium bromide and add it to 100 parts by weight of deionized water, which contains 0.5% by weight of sodium hydroxide, Hexadecyltrimethylammonium bromide contains 3% by weight of triethanolamine, heat to 80°C, continue to stir at constant temperature for 30 minutes, then drop in 5 parts by weight of tetraethyl orthosilicate at a uniform speed, control the time at about 10 minutes, continue After stirring and reacting at constant temperature for 2 hours, take it out and separate it with a centrifuge at 10,000 rpm for 10 minutes to obtain a white solid, dry it in vacuum at 80°C for more than 12 hours, and then place it in a muffle furnace for calcination at 300°C for 10 hours to obtain porous silica Nano-ion, the size of porous silica nano-ion is between 200-300nm, and the pore size is 6-10nm;

[0072] (2) The prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com