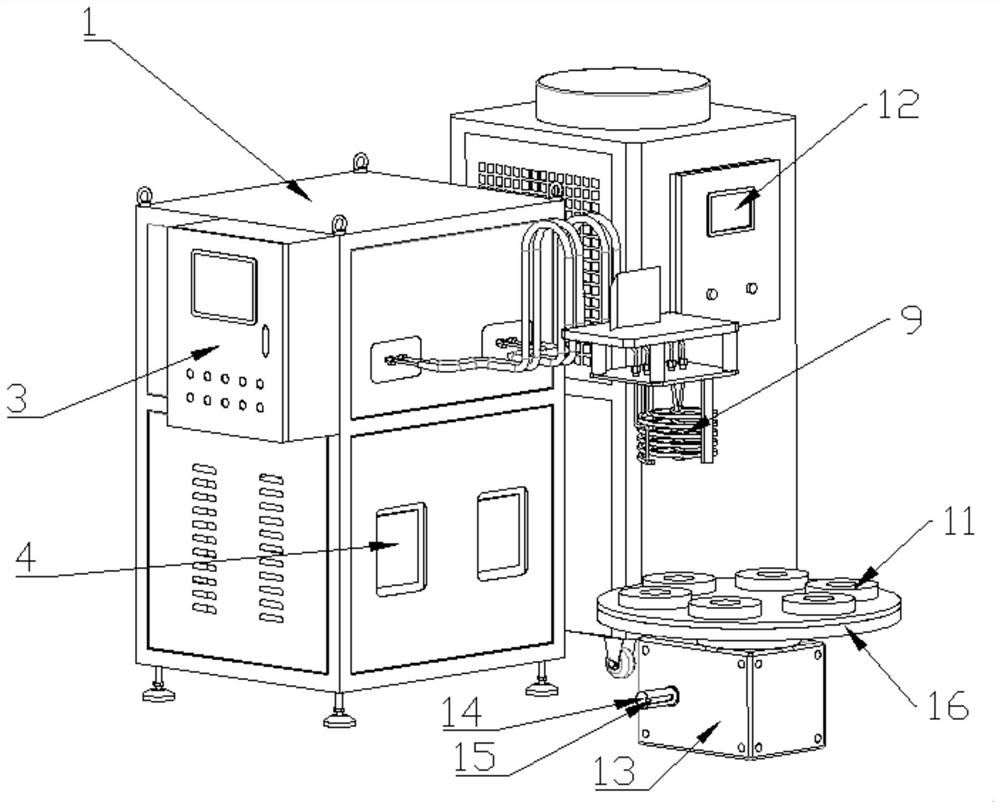

Medium-frequency internal and external simultaneous heating equipment for rotor core of new energy motor

A technology for motor rotors and heating equipment, which is applied in the manufacture of motor generators, electrical components, electromechanical devices, etc. It can solve the problems of inconvenient use of devices, achieve the effects of improving efficiency, improving technology, and reducing heat source leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

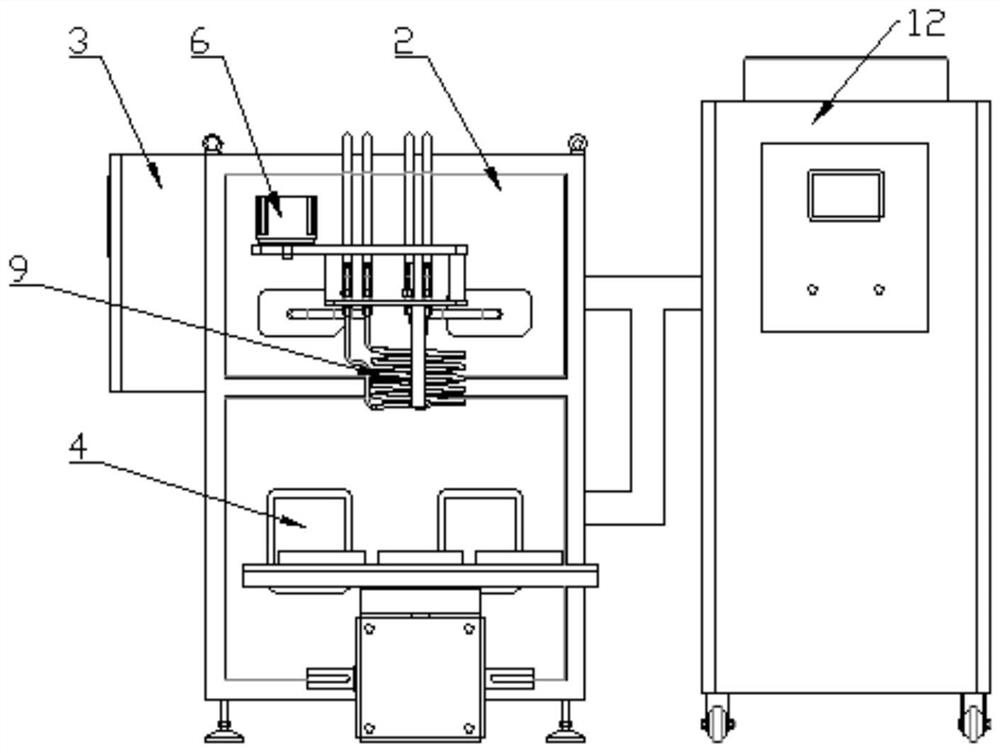

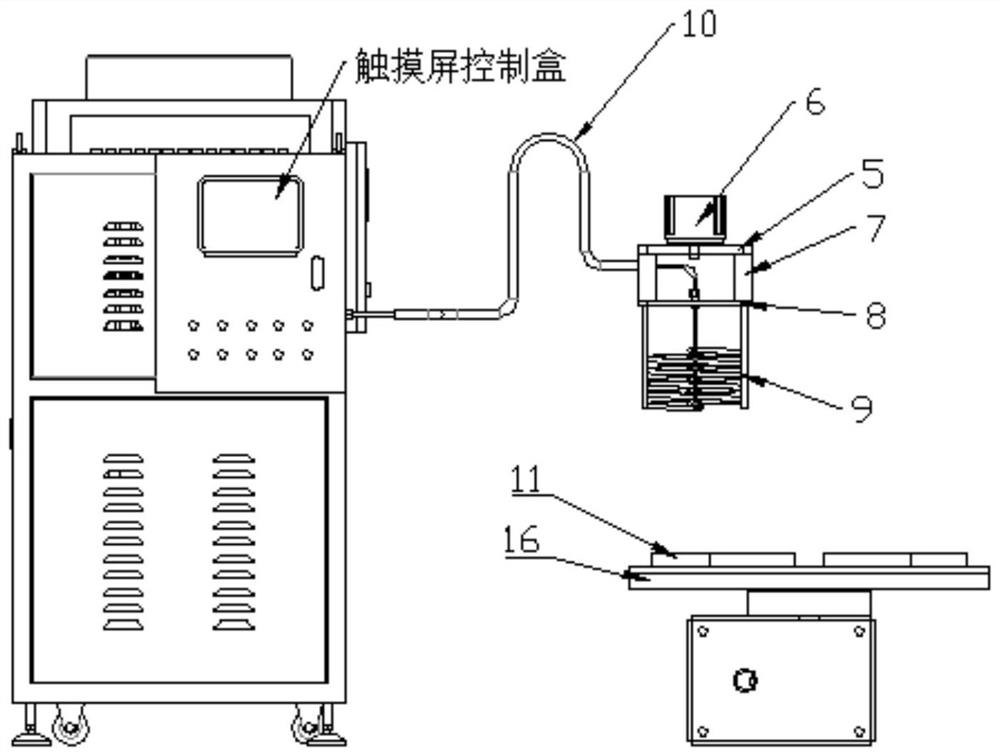

[0016] Embodiment: When in use, the hydraulic cylinder 6 is first fixedly installed on the external frame of the equipment, and the rotor heating inductor 9 includes an external heating coil and an internal heating coil. The machine has two modes, manual and automatic, and manual operation is mainly for operation For the first time, the operator is unfamiliar with the relationship between time and temperature according to the number of stacked rotor cores. He can compare the relationship between time and temperature with an infrared thermometer while heating, and set an appropriate temperature curve in the PLC program (multiple groups can be set Parameters, according to the stacking height, the PLC pre-stored program is automatically called on the touch screen in the later stage); in the automatic mode, the process parameters are mainly tested and calculated for many times, and the correct time and temperature curves are set, and the robot only needs to unload and stack with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com