Longitudinal bending composite ultrasonic vibration reciprocating sternum saw

A composite ultrasound and sternum technology, applied in the direction of surgical saws, etc., can solve the problems affecting patient comfort and postoperative recovery, low transmission efficiency of ultrasonic bone knife, poor stability, etc., to facilitate postoperative recovery and improve the quality of the cutting surface , Reduce the effect of cutting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

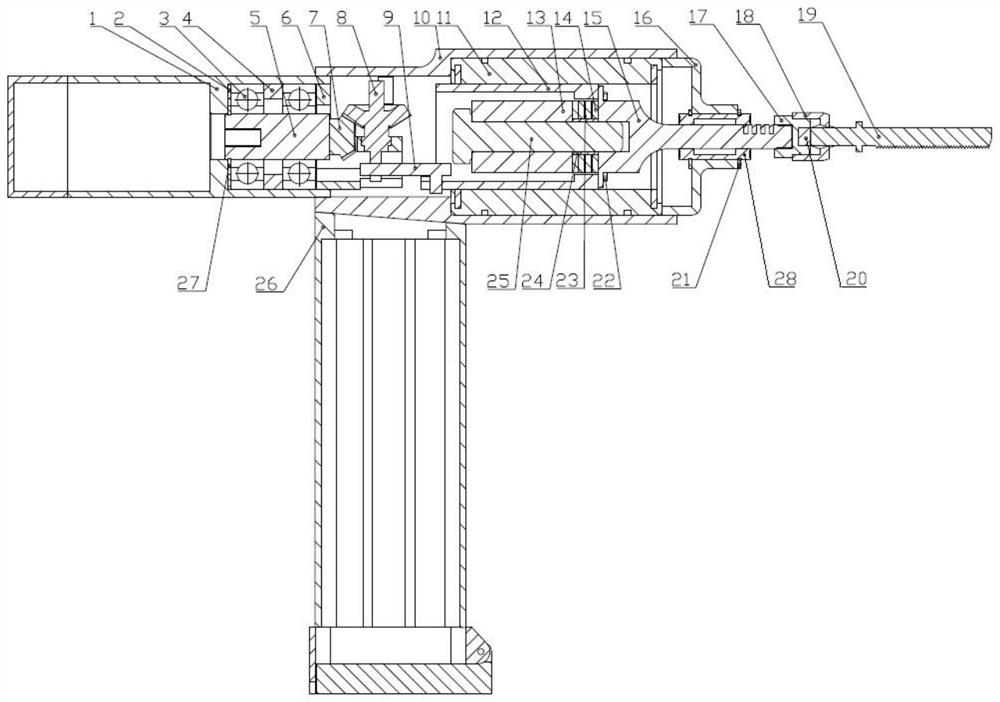

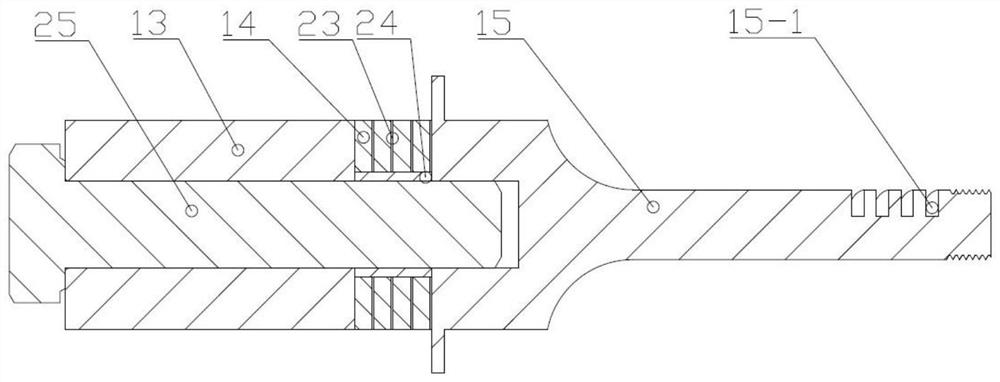

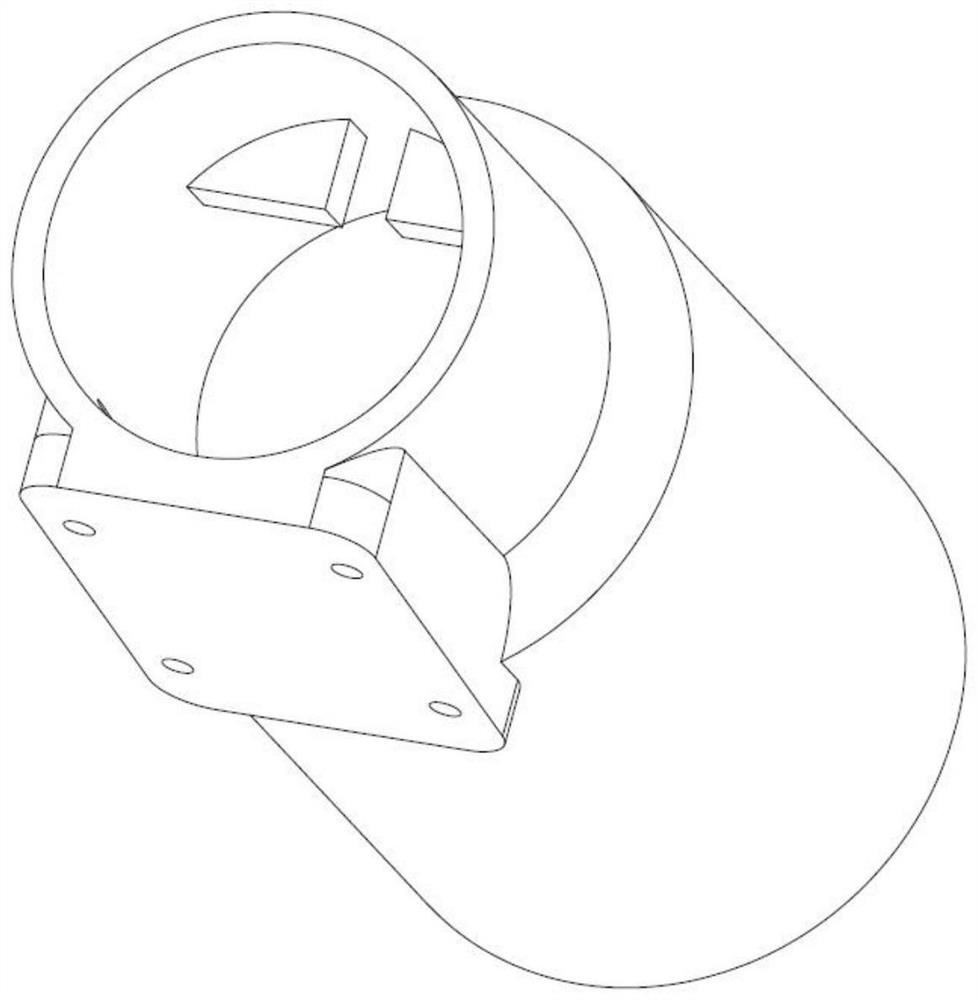

[0054] as attached Figure 1 to Figure 10 As shown, a longitudinal bending composite ultrasonic vibration reciprocating sternum saw includes a body and a saw blade 19, wherein the body mainly includes three parts, the saw blade chuck, the main body of the sternum saw and the tail of the sternum saw, which are sequentially connected.

[0055] The saw blade chuck is used to clamp the saw blade 19. In this embodiment, the existing saw blade chuck is adopted, and the saw blade chuck includes a collet base 17, a collet 20 for clamping the saw blade 19, and a collet that cooperates with the collet base 17 to clamp the collet 20. Collet nut 18, insert the saw blade 19 into the collet 20, and then tighten the collet nut 18 to realize the complete fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com