Barrier coating, preparation method thereof and recyclable paper

A technology of barrier coating and acrylic emulsion, which is applied in coating, papermaking, paper coating, etc., and can solve the problems that materials cannot be recycled and construction is complicated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

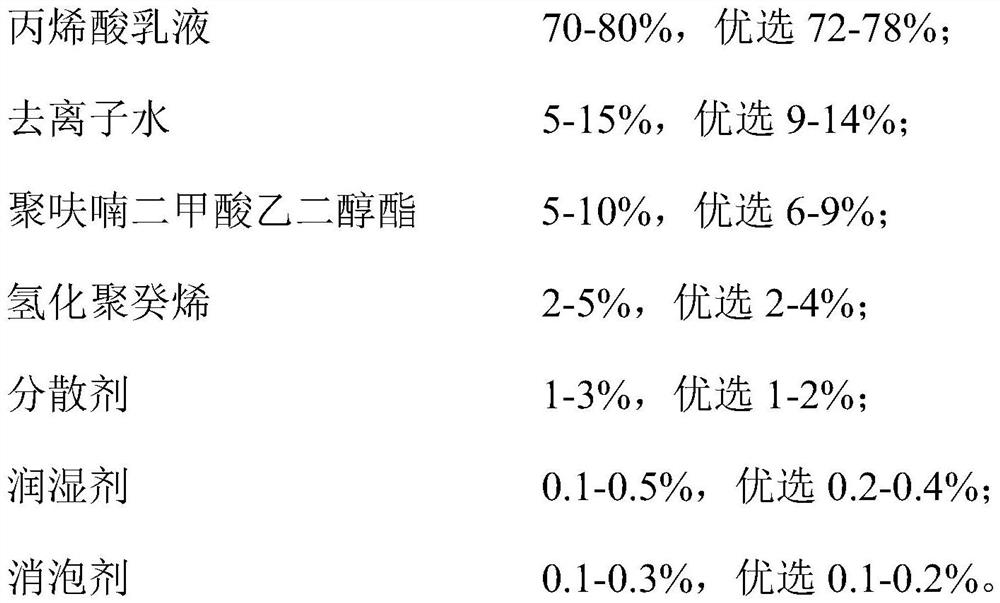

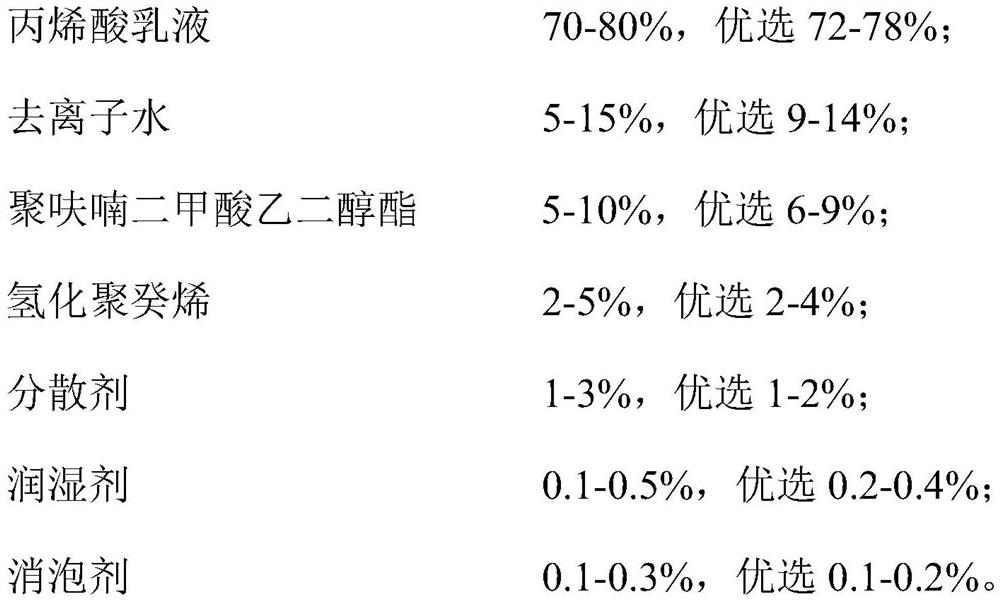

Method used

Image

Examples

Embodiment 1

[0028] (1) Add 10 parts of PEF-30, 5 parts of hydrogenated polydecene, and 2 parts of BYK-190 into the dispersion tank, heat to 70°C, add 12.5 parts of water to disperse, and cool to room temperature.

[0029] (2) 70 parts of Add to the above blend under stirring condition, add 0.3 parts of BYK-346 and 0.2 parts of AIRASE-5355 in turn, and then discharge.

[0030] Substrate: 250g / m 2 White cardboard, coating method: knife coating, drying condition: 100℃, 30s. Coating amount: 12g / m 2 .

Embodiment 2

[0032] (1) 5 parts of Dagot-90, 5 parts of hydrogenated polydecene, 1 part Add HLD-69 into the dispersion tank, heat to 90°C, add 8.7 parts of water to disperse, and cool to room temperature.

[0033] (2) put 80 copies of Add to the above blend under stirring condition, add 0.2 part of BYK-348, 0.1 part of Foamaster WO 2360 in sequence, and then discharge.

[0034] Substrate: 250g / m 2 White cardboard, coating method: blade coating, drying condition: 80°C, 40s. Primer coating amount: 6g / m 2 .

Embodiment 3

[0036] (1) Add 8 parts of Dagot-90, 2 parts of hydrogenated polydecene, and 1 part of BYK-190 into the dispersion tank, heat to 60°C, add 13.5 parts of water to disperse, and cool to room temperature.

[0037] (2) 75 parts of Add to the above blend under stirring condition, add 0.3 parts of BYK-348 and 0.2 parts of AIRASE-5355 in sequence, and then discharge.

[0038] Substrate: 250g / m 2 White cardboard, coating method: knife coating, drying condition: 120°C, 30s. Primer coating amount: 20g / m 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com