Coolant, preparation method thereof, temperature-sensitive flocculating gel and aerosol fire extinguishing device

A coolant and aerosol technology, applied in chemical instruments and methods, fire prevention equipment, heat exchange materials, etc., can solve problems such as protective objects to be studied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

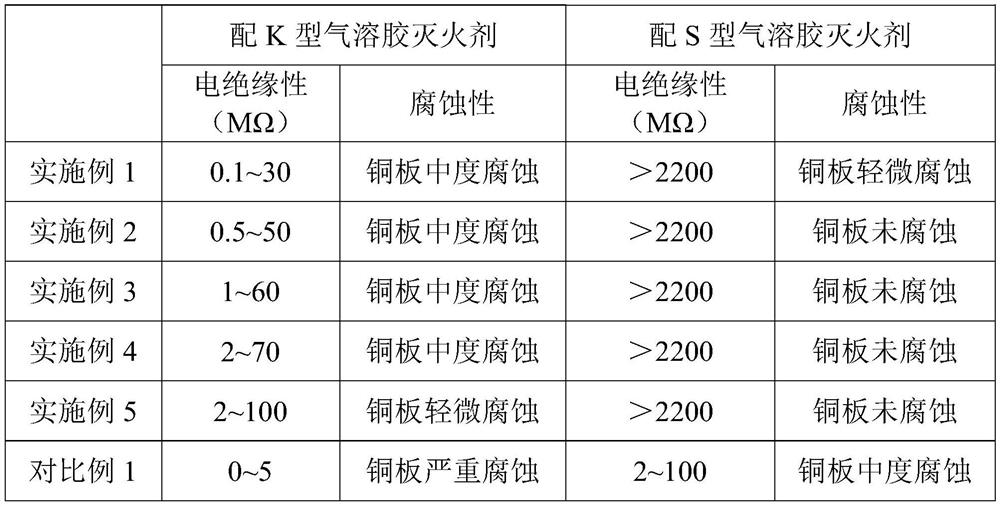

Examples

preparation example Construction

[0061] An embodiment of the present invention also provides a method for preparing a coolant as in any of the above examples, including the following steps S110 to S120.

[0062] Step S110: mixing organic acid powder and organic polyol powder.

[0063] Further, the mixing time is 15 minutes to 60 minutes. Mix organic acid powder and organic polyol powder well and evenly.

[0064] Step S120: Dissolving the binder powder in a volatile organic solvent to form a solution; adding the solution to the mixture consisting of organic acid powder and organic polyol powder, mixing evenly, sieving, and granulating.

[0065] Further, after the solution is added to the mixture composed of the organic acid powder and the organic polyol powder, the mixing time is 15 minutes to 60 minutes. Make the binder fully mix with organic acid and organic polyhydric alcohol.

[0066] Further, the standard mesh size used for sieving before granulation is 10 mesh to 40 mesh.

[0067] Furthermore, drying...

Embodiment 1

[0077] 1. Pretreatment: The raw materials furoic acid, 4-methylcinnamic acid, cinnamyl alcohol and carboxymethyl cellulose are pulverized respectively, passed through a 200-mesh standard sieve after pulverization, and then the raw materials are dried.

[0078] 2. Coolant preparation:

[0079] (1) The raw material after pretreatment is weighed by mass percentage, 15% furoic acid, 40% 4-methyl cinnamic acid, 40% cinnamyl alcohol and 5% carboxymethyl cellulose.

[0080] (2) Stir and mix the furoic acid, 4-methylcinnamic acid and cinnamyl alcohol weighed in step (1) in a powder mixer for 30 minutes, and transfer the powder mixture to a wet material mixer after the stirring is completed.

[0081] (3) The carboxymethyl cellulose taken by step (1) is dissolved in ethanol, the carboxymethyl cellulose is completely dissolved to form a solution, and the solution is added to the wet material mixer of step (2) with furoic acid, Mix 4-methylcinnamic acid and cinnamyl alcohol, stir for 15 ...

Embodiment 2

[0084] 1. Pretreatment: The raw materials behenic acid, terephthalic acid, pinacol, and methyl cellulose are pulverized separately, passed through a 200-mesh standard sieve after pulverization, and then the raw materials are dried.

[0085] 2. Coolant preparation:

[0086] (1) The raw materials after pretreatment were weighed by mass percentage, including 10% behenic acid, 45% terephthalic acid, 40% pinacol and 5% methylcellulose.

[0087] (2) Stir and mix the behenic acid, terephthalic acid, and pinacol in the powder mixer for 35 minutes in the step (1), and transfer the powder mixture to the wet material mixer after the stirring is completed.

[0088] (3) Dissolve the methyl cellulose taken by step (1) in ethanol to dissolve the methyl cellulose completely to form a solution, add the solution to the wet material mixer of step (2) with behenic acid, Mix phthalic acid and pinacol, stir for 20 minutes to make the mixture evenly mixed, then transfer the mixture to a granulator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com