Cold-grinding sharp-turning hot-melting type separation and regeneration equipment and regeneration method for waste asphalt

A technology for waste asphalt and recycling equipment, applied in roads, buildings, road repair and other directions, can solve the problems of asphalt performance impact, reduced pavement structural strength, difficult to remove, etc., to improve separation efficiency, reduce toughness, and facilitate separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, not to limit the present invention.

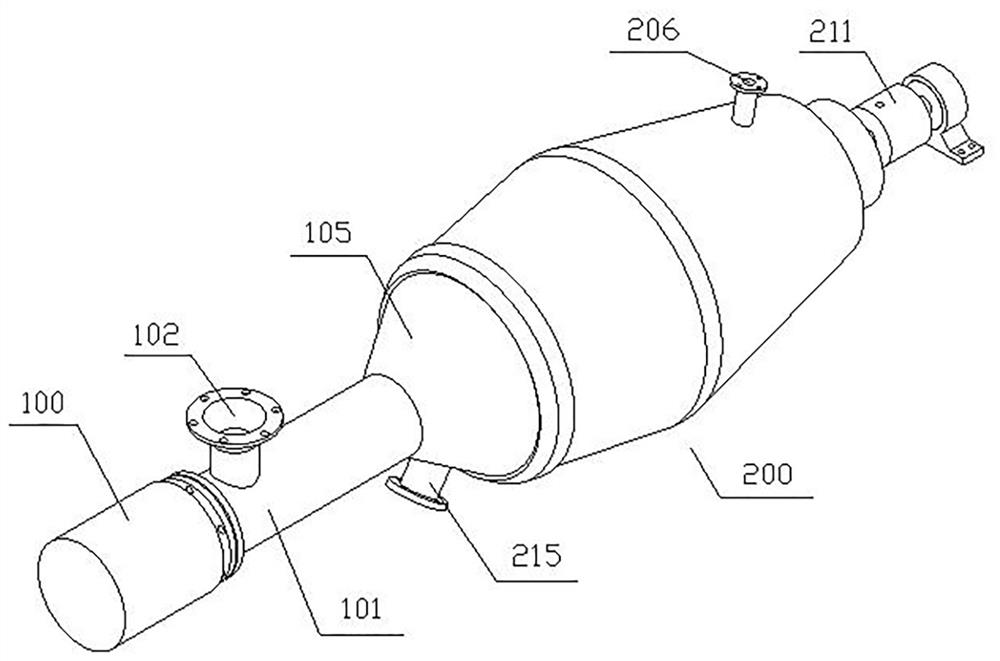

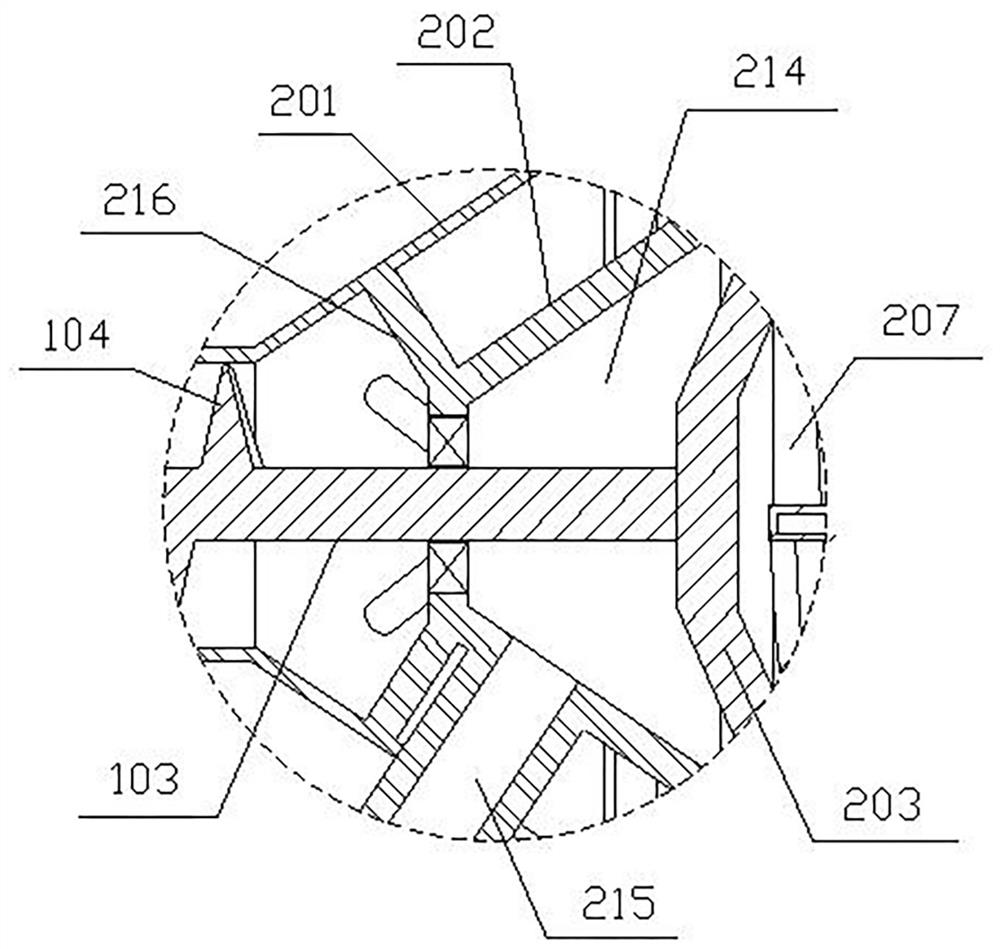

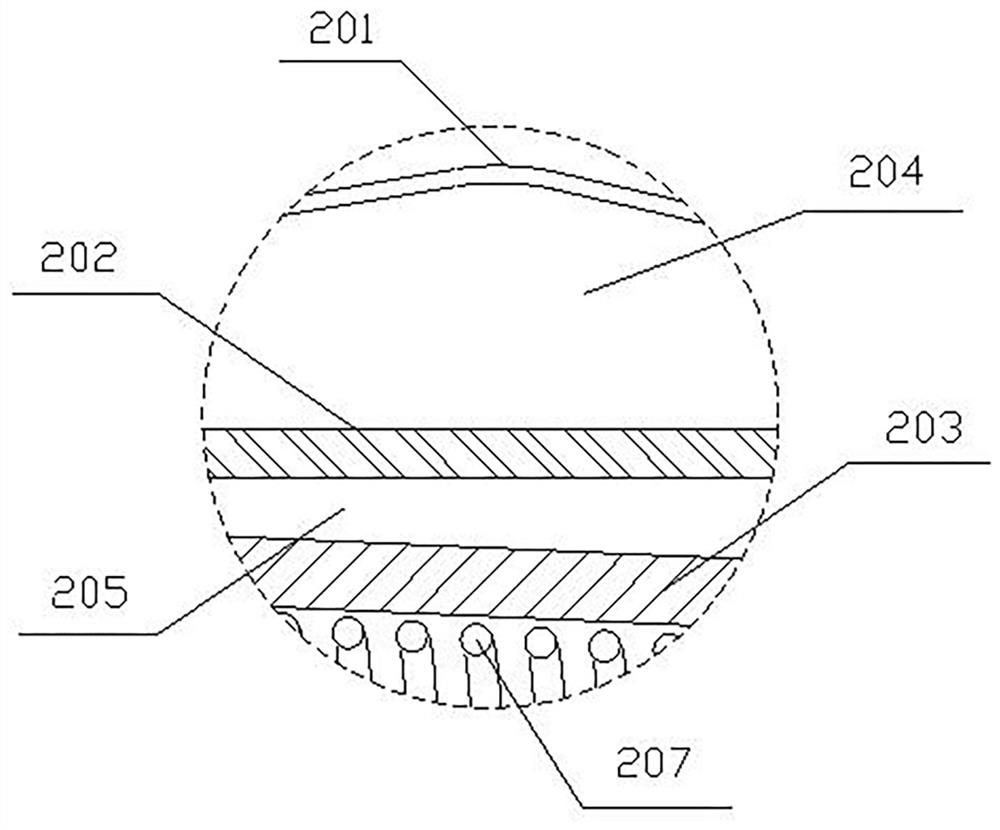

[0039] The invention discloses a waste asphalt cold-grinding and rapid-turning hot-melt separation regeneration equipment, such as Figure 1-12 As shown, it includes a cold grinding mechanism 200 and a hot melt mechanism, wherein the material from the outlet end of the cold grinding mechanism 200 is sieved through a material sieve, so that the asphalt powder is sieved out and collected, and is sieved by the material sieve The separated asphalt stone coating body and asphalt sand material coating body containing stone and sand material enter the hot melt mechanism through the inlet of the hot melt mechanism, and the stone material, sand material and asphalt are separated by hot melting; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com