Method and device for protecting combustion chamber of internal combustion engine and improving combustion efficiency

A combustion efficiency and combustion chamber technology, applied in combustion air/combustion-air treatment, adding non-fuel substances to fuel, charging system, etc., can solve the problem of unsatisfactory fuel saving effect, poor carbon deposit removal effect, and reduced power performance. and other problems, to achieve the effect of improving fuel combustion efficiency, simple and reasonable structure, and reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will now be further described in conjunction with the accompanying drawings and specific embodiments, wherein the controller, additive box, atomizer, air compressor, atomization chamber, proportional valve and check valve are all existing structural components, so in the description No specific structural description will be made, and the new design part will be described in detail in the following embodiments.

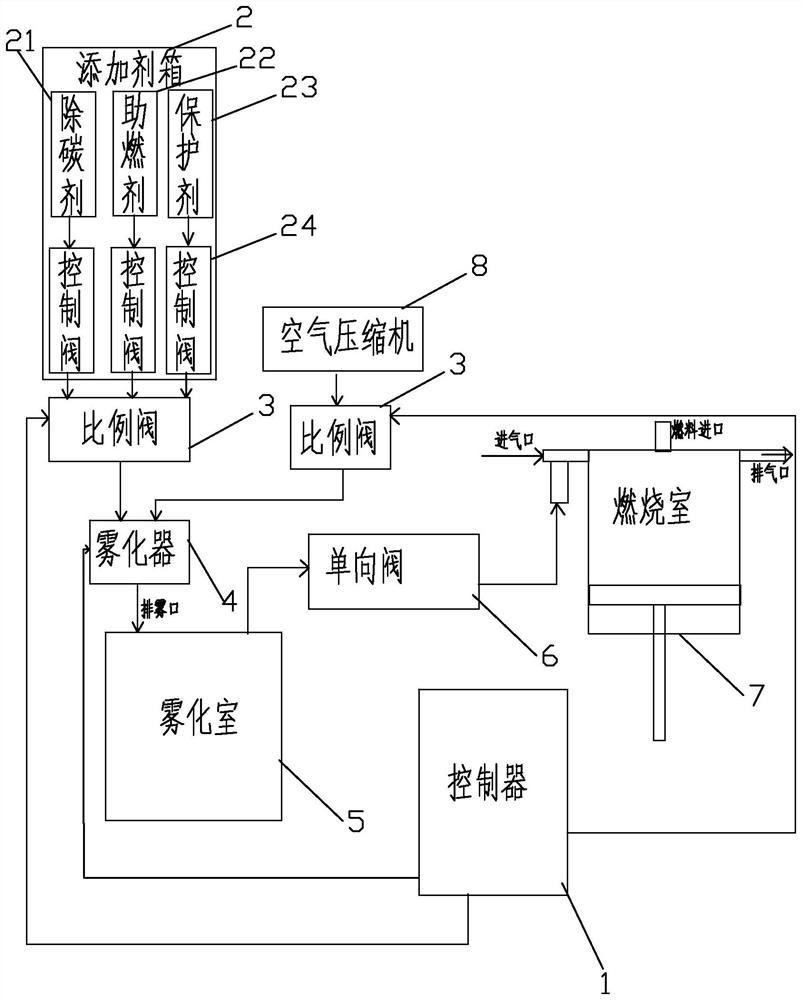

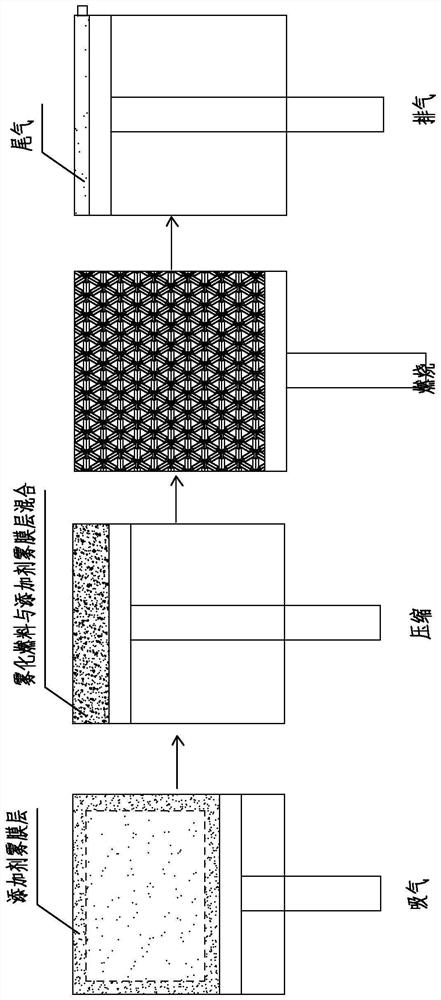

[0020] refer to figure 1 , the preferred device for protecting the combustion chamber of an internal combustion engine and improving combustion efficiency of the present invention includes a controller 1, an air compressor 8, three control valves 24, an additive box 2, an atomizer 4, an atomizing chamber 5, and two proportional valve 3 and one-way valve 6, the additive box 2 is divided into three units and the carbon remover 21, combustion accelerant 22 and protective agent 23 are respectively placed in the three units, and the decarburize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com