Efficient feeding transmission device suitable for stacking wafers

A kind of transmission device, high-efficiency technology, applied in the direction of transportation and packaging, sustainable manufacturing/processing, electrical components, etc., can solve the problems of unfavorable adsorption of different materials or wafers, inconvenient adjustment, small capacity of wafer cassettes, etc., to achieve The effect of reducing the risk of wafer drop, increasing work efficiency, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

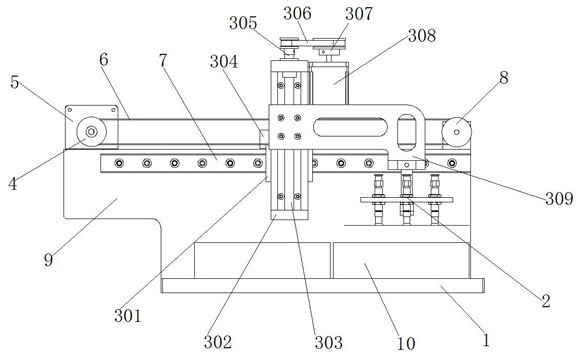

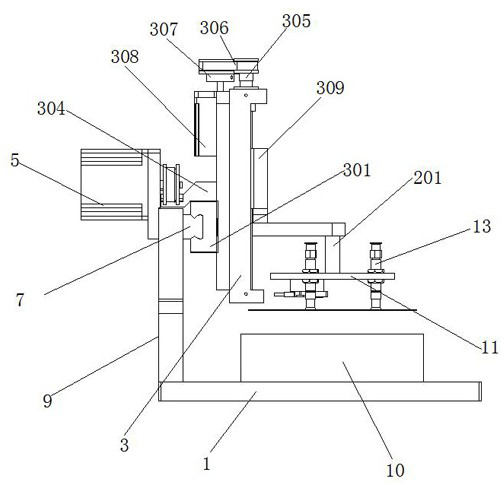

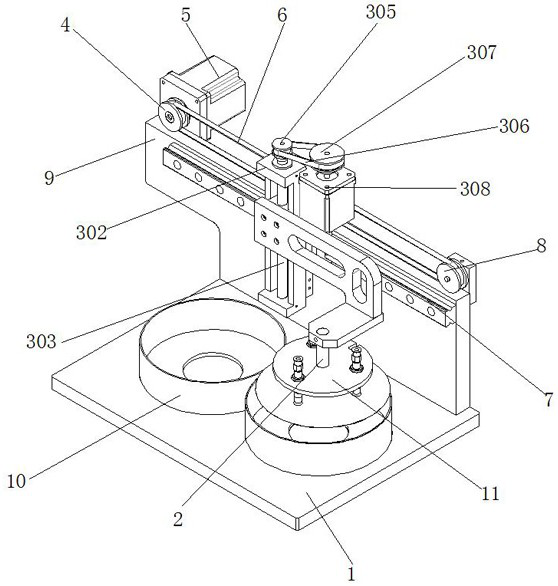

[0038] Example 1, such as Figure 1-4 As shown, the circular magazine 10 filled with wafers is placed above the bottom plate 1 of the magazine, and the second servo motor 5 drives the first synchronous tooth profile through the second driving pulley 4 and the second driven pulley 8. The belt 6 reciprocates horizontally, and the 匚-shaped plate 302 moves horizontally reciprocatingly through the timing belt splint 304 clamped on the first synchronous toothed belt 6 at the same time, and the sliding sleeve 301 on the 匚-shaped plate 302 guides and slides on the guide rail 7 , to ensure the stability and precision of the movement of the 匚-shaped plate 302, the first servo motor 308 works to drive the first driven pulley 305 and the first driving pulley 307 to rotate, and at this time drives the threaded rod 303 to perform forward and reverse rotation, so that the connection The arm 309 moves in the vertical direction, sucks the wafer inside the round magazine 10 through the three va...

Embodiment 2

[0039] Example 2, such as Figure 5-6 As shown, when the vacuum suction head 13 needs to be replaced, the hinge block 204 is pushed at this time to make the two sets of second hinge rods 210 rotate to change positions, and then under the restriction of the limit rod 206, the two sets of L-shaped rods 207 are The horizontal direction is far away from each other. At this time, the vacuum suction head 13 can be unrestricted. At this time, the vacuum suction head 13 can be slid in the installation groove 12, and the vacuum suction head 13 can be replaced, and then the other vacuum suction head 13 can be replaced. The suction head 13 slides to the inside of the installation groove 12 and between the two sets of arc splints 208, under the elastic force of the spring 205, the hinge block 204 is reset, so that the two sets of arc splints 208 are close to each other to clamp the vacuum suction head 13 Live fixed.

[0040] Working principle: Place the round material box 10 full of wafe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com