Small polymer battery processing equipment

A kind of processing equipment and polymer technology, which is applied in the field of small polymer battery processing equipment, can solve the problems of inconsistent product quality, high manual labor intensity, high production cost, etc., and achieve the effect of high degree of automation, reduced labor cost, and consistent processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

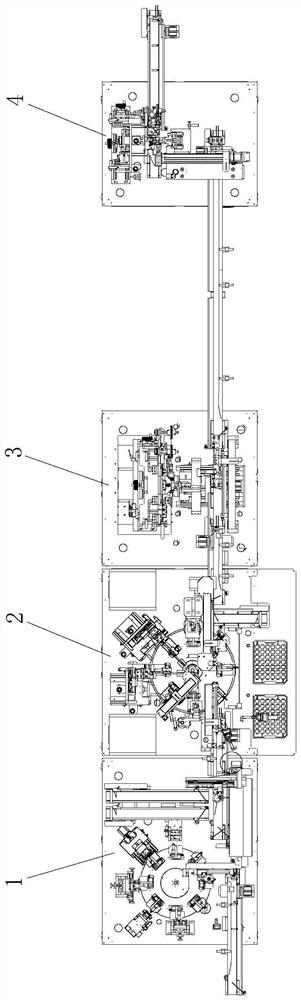

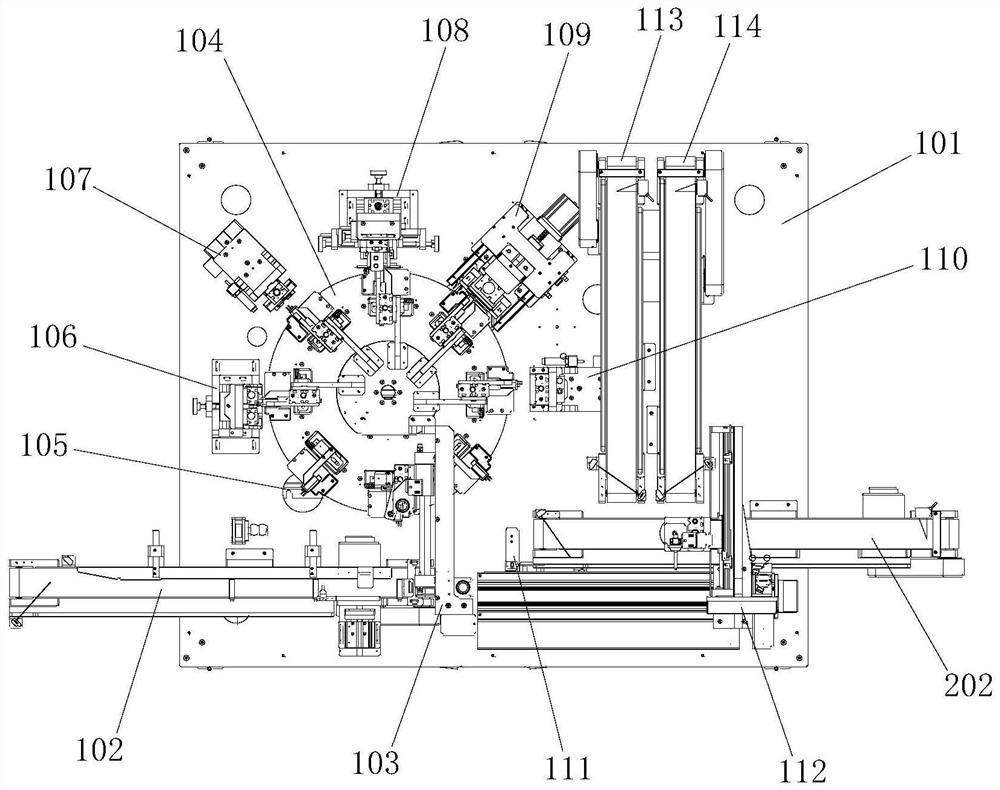

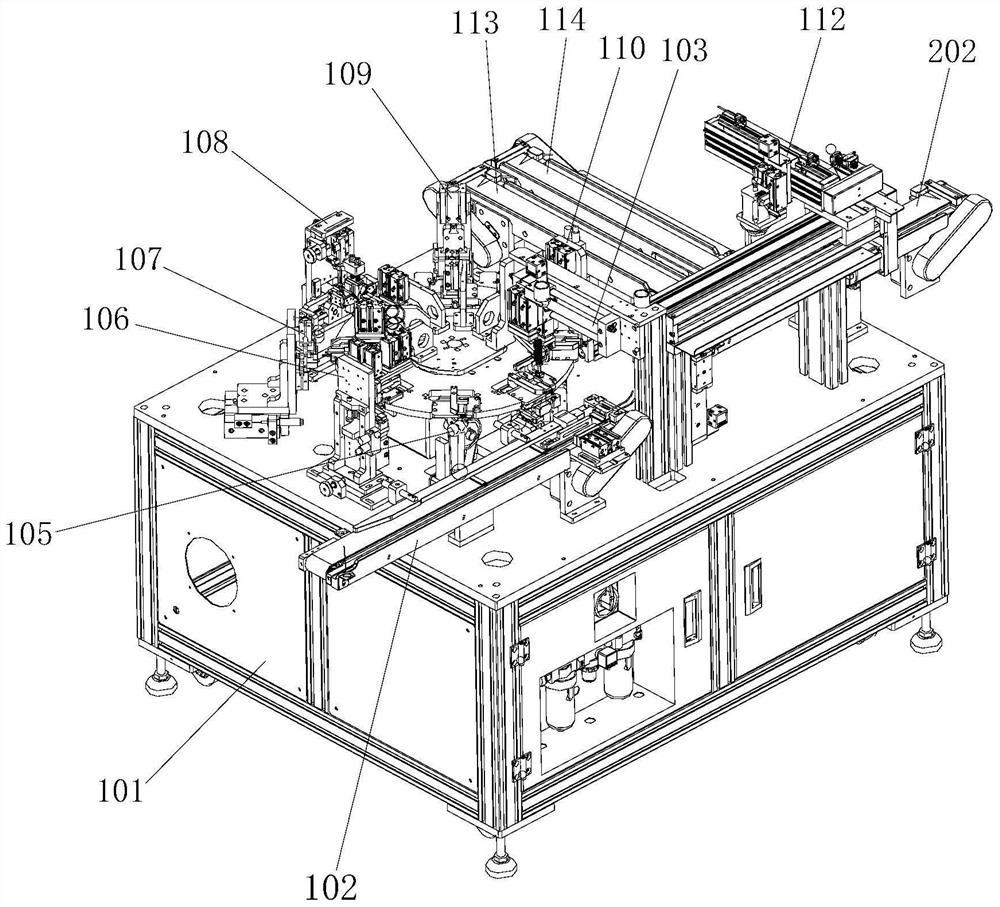

[0043] see figure 1 , this embodiment provides a small polymer battery processing equipment, the small polymer battery processing equipment is combined with a tab shearing machine 1, an automatic double-station resistance welding machine 2, and a head gluing machine 3 along the battery processing direction And the head winding machine 4, among which the tab shearing machine 1 can automatically complete the loading, OCV test, cup mouth shaping, side voltage test, tab cutting, tab leveling, good and defective product unloading, automatic The double-station resistance welding machine 2 can realize automatic docking with the tab shearing machine 1, combined with manual loading of the battery protection board, to complete the automatic deviation correction welding of the battery protection board and the battery, and the head gluer 3 can be connected with the automatic duplex The position resistance welding machine 2 realizes automatic docking, and through the up and down dislocatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com