Sucker rod cleaning device

A technology for cleaning devices and sucker rods, applied in cleaning methods and tools, cleaning methods using liquids, cleaning methods using tools, etc., can solve the problems of sucker rod body corrosion, low work efficiency, and easy to be polluted, etc. Achieve the effect of quickly loosening dirt and avoiding inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

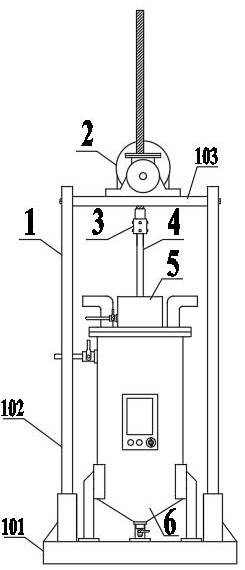

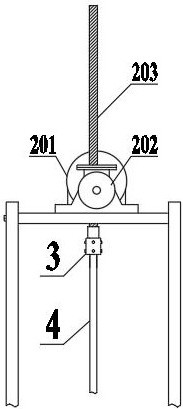

[0048] Such as figure 1 As shown, the sucker rod cleaning device includes a load-bearing frame 1, a screw lifter 2, a connecting device 3, a flushing device 5, and a heating device 6. In the figure, the load-bearing frame 1 is the main part, specifically composed of a base 101, two vertical plates 102 and horizontal plate 103 are formed, and two vertical plates 102 are oppositely arranged, and horizontal plate 103 is installed between two vertical plates 102, and the two ends of horizontal plate 103 are fastened by screw. figure 2 Among them, the lead screw lifter 2 is arranged on the top of the horizontal plate 103, the lead screw lifter 2 includes a motor 201, a transmission gear box 202 and a lead screw 203, the motor 201 drives the lead screw 203 to move up and down through the transmission gear box 202, and the transmission gear box 202 is In the existing structure, in the figure, the connecting device 3 is installed on the bottom of the lead screw 203 for fixing the suc...

Embodiment 2

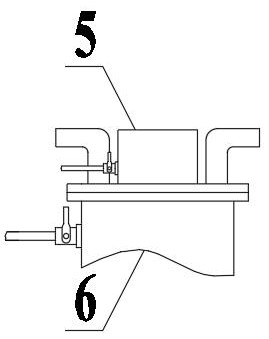

[0051] Such as Figure 4 As shown, the flushing device 5 includes a cavity 501 and a flange 502 located at the bottom of the cavity 501. The inner wall of the cavity 501 is provided with an annular high-pressure pipeline 503, and a plurality of high-pressure nozzles 504 are evenly distributed on the high-pressure pipeline 503, wherein : The high-pressure pipeline 503 includes a single-layer or multi-layer loop, and the high-pressure nozzles 504 on the loop are arranged in a staggered manner. Specifically, in this embodiment, two rows of high-pressure pipelines 503 are arranged in parallel. Specifically, the spraying directions of the high-pressure nozzles 504 all point to the central position, and the spraying angle can be horizontal or inclined downward by 5°-30°.

[0052] It should be noted that the flushing device 5 can also be equipped with a cover 505, and the cover 505 and the cavity 501 are connected by threads. Figure 5 Among them, the inner wall of the cover body 5...

Embodiment 3

[0055] Such as Figure 8 As shown, the heating device 6 includes a heating tank 601, a water inlet pipe 602, a sewage discharge pipe 603, an air inlet 604, an exhaust port 605 and a temperature control box 606, wherein: the water inlet pipe 602 is installed on the upper part of the side wall of the heating tank 601, and the sewage discharge The pipe 603 is installed at the bottom of the heating tank 601, and the liquid added can be clear water or cleaning liquid. The air inlet 604 and the exhaust port 605 are both arranged on the top of the heating tank 601, the air inlet 604 and the exhaust port 605 can be closed freely, and a fan is connected to discharge steam, and the temperature control box 606 is arranged on the side of the heating tank 601 For adjusting the temperature, the heating device 6 can adopt the prior art, and this embodiment is used to show the layout structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com