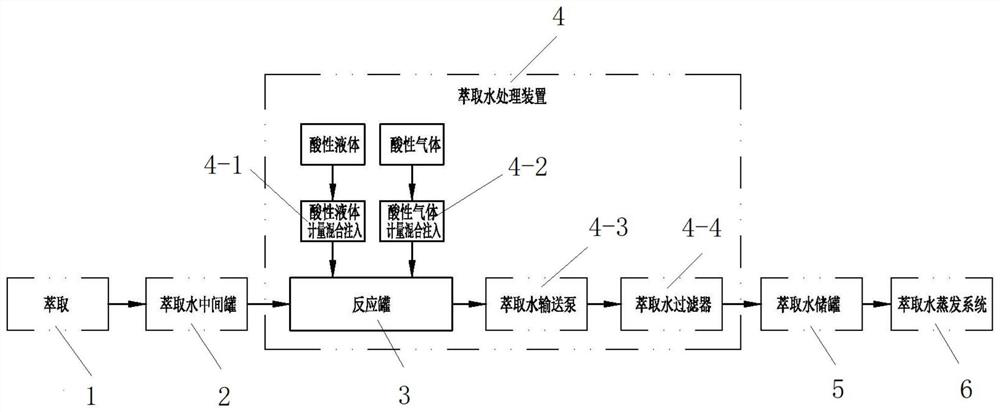

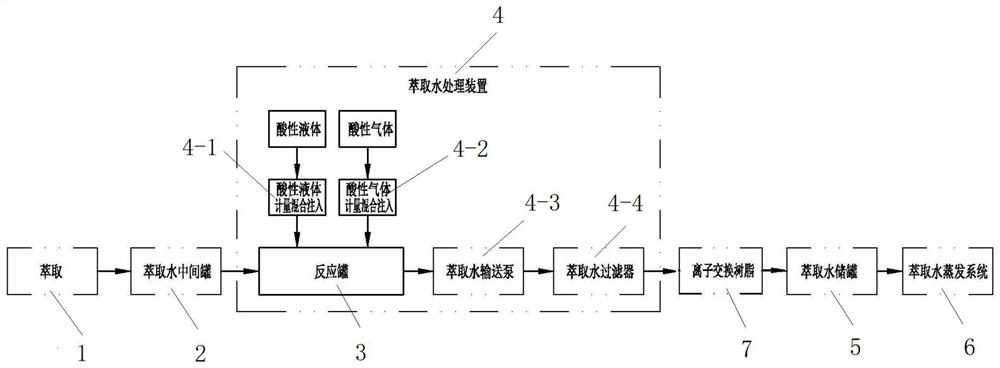

Device, system and process for treating PA6 polymerization extraction water

A treatment device and water extraction technology, applied in natural water treatment, water treatment parameter control, heating water/sewage treatment, etc. Limit and other issues, to reduce the number of cleaning and replacement, prolong the continuous running time, improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] In an existing production facility of an enterprise, the extracted water is directly fed into the extracted water storage tank from the extracted water intermediate tank without other treatment, and then reused after being evaporated and concentrated.

[0043] The situation of the above-mentioned implementation factories before the transformation is as follows:

[0044] Inorganic ions in the extracted water are continuously enriched during the recycling process. After the enrichment reaches a certain concentration, the normal production is seriously affected, resulting in a very short operating period of the melt filter in the recycled material polymerization line, sometimes even 2 to 3 days, which has seriously affected normal operation of production. If the current common treatment method "ion exchange resin device" is used to treat monomer water, the initial investment of the equipment is about 3 million yuan, most of which is the cost of ion exchange resin. The ion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com