Nanometer foam glass bead concrete capable of being used for door plate and preparation method of nanometer foam glass bead concrete

A technology of glass microbeads and nano-foam, which is applied in the field of concrete, can solve the problems of restricting the application of foam concrete and the decrease of strength, achieve good mechanical strength effects, reduce shrinkage and warping, and reduce the effect of foam breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

[0046] Embodiment 1-8: the preparation of nano-foam glass bead concrete

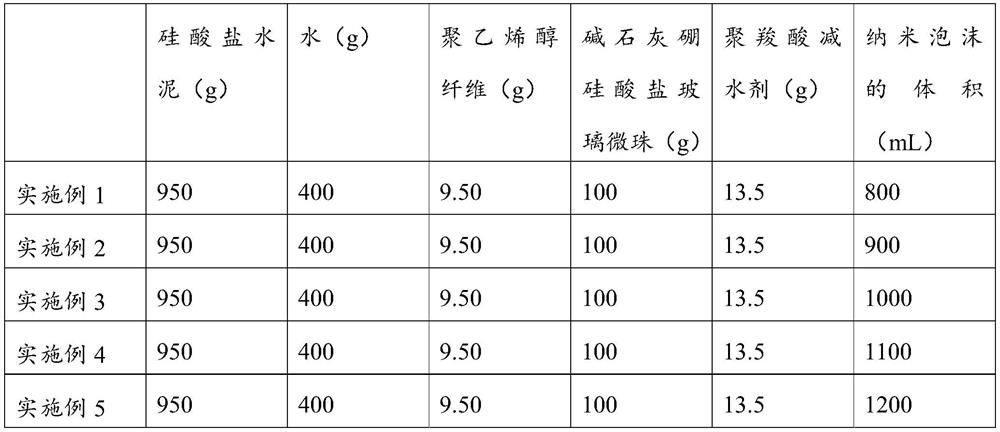

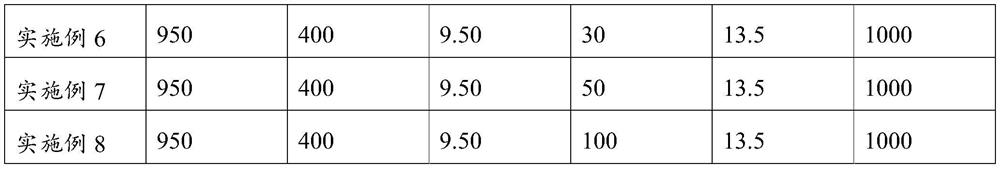

[0047] Table 1 shows the raw material components and amounts thereof used to prepare the nano-foam glass bead concrete of Examples 1-8.

[0048] Table 1

[0049]

[0050]

[0051] The preparation method of embodiment 1-8 nano-foam glass bead concrete, comprises the following steps:

[0052] (1) Pour Portland cement into the mixing pot and stir slightly (stirring speed is 50 rpm), then add water and stir to mix (the process of stirring and mixing is divided into two stages, the first stage is at 50 rpm Stirring at a high speed for 30s, the second stage is stirring at a speed of 140 rpm for 1 minute), then adding polyvinyl alcohol fibers, then adding glass microspheres (the particle size of the glass microspheres is 60-65μm), and the glass The microbeads were added in 10 times, and the quality of the glass microbeads added in the first 9 times was 1 / 2 of the remaining glass microspheres, and stirre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com