Method and device for rapidly measuring residual gas content of underground coal sample

A gas content and rapid determination technology, applied in measuring devices, sampling, fuel oil testing, etc., can solve the problems that electric energy cannot be easily obtained underground, easy to generate electric sparks, and cannot quickly obtain measurement results, etc., so as to improve the efficiency of parameter measurement As well as the accuracy of the measurement results, the convenience of repair and maintenance, and the effect of good use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

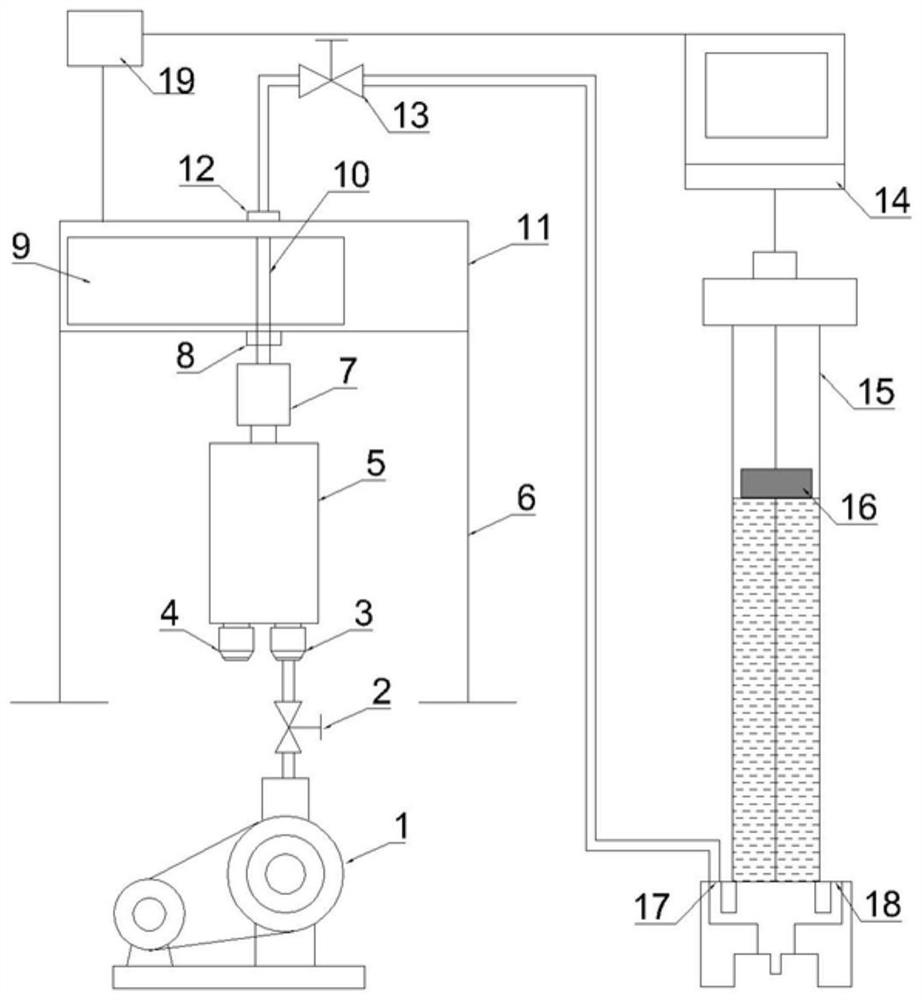

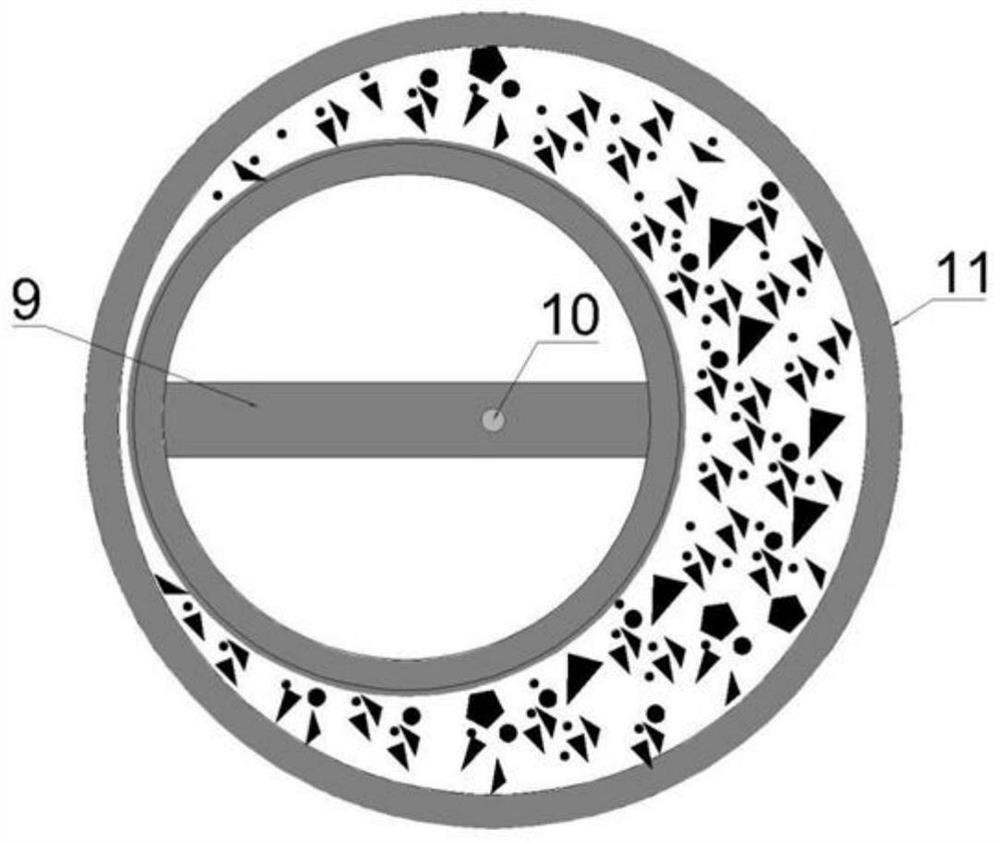

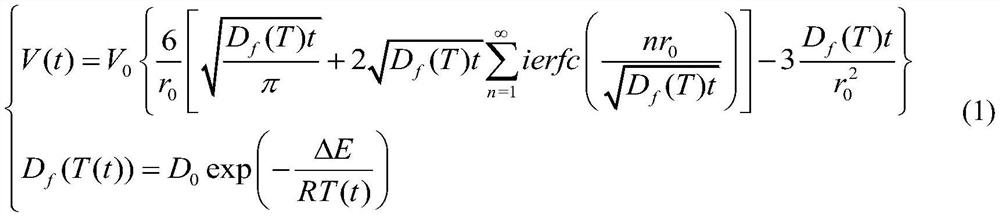

[0032] Such as figure 1 and figure 2 As shown, a rapid determination method for the residual gas content of underground coal samples. There is a certain mathematical relationship between the residual gas content of coal samples and the gas desorption law. By measuring the gas desorption data of coal samples for 10 to 20 minutes underground, the mathematical method for the gas desorption law of coal samples is established. Model, further can accurately calculate residual gas content, the present invention comprises the following steps:

[0033] ①Collect coal samples on site in the coal mine, put the coal samples to be tested into the crushing tank 11, fill the desorption measuring cylinder 15 with water, and reset the liquid level gauge 16 to zero;

[0034] ② Connect the underground compressed air source 1, open the needle valve I2 and needle valve II13, start the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com