In-situ battery device for soft X-ray microscopic imaging

A technology for microscopic imaging and battery devices, which can be used in measuring devices, secondary battery testing, and secondary battery repair/maintenance. It can solve problems such as irreversible changes, technical difficulties, and high prices, and achieve accurate and high-resolution soft X-rays. Imaging, wide applicability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

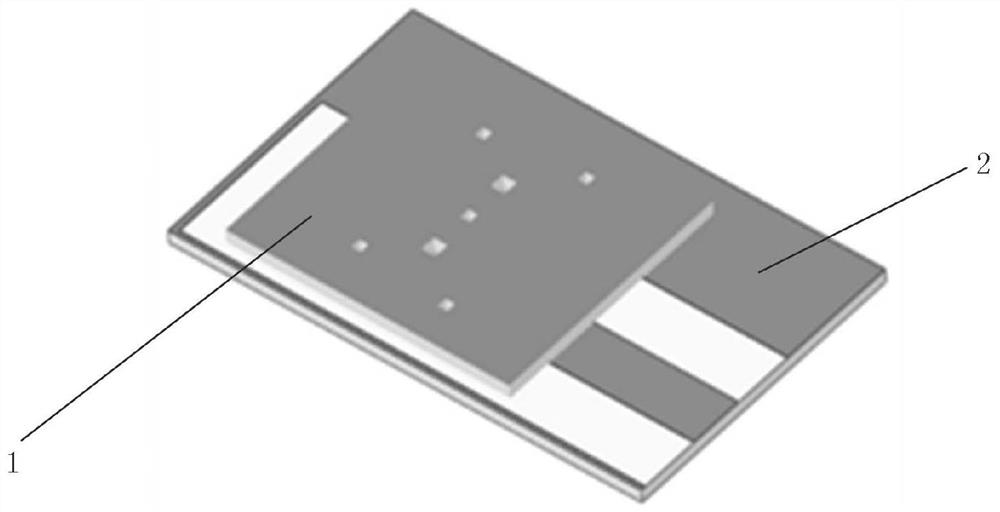

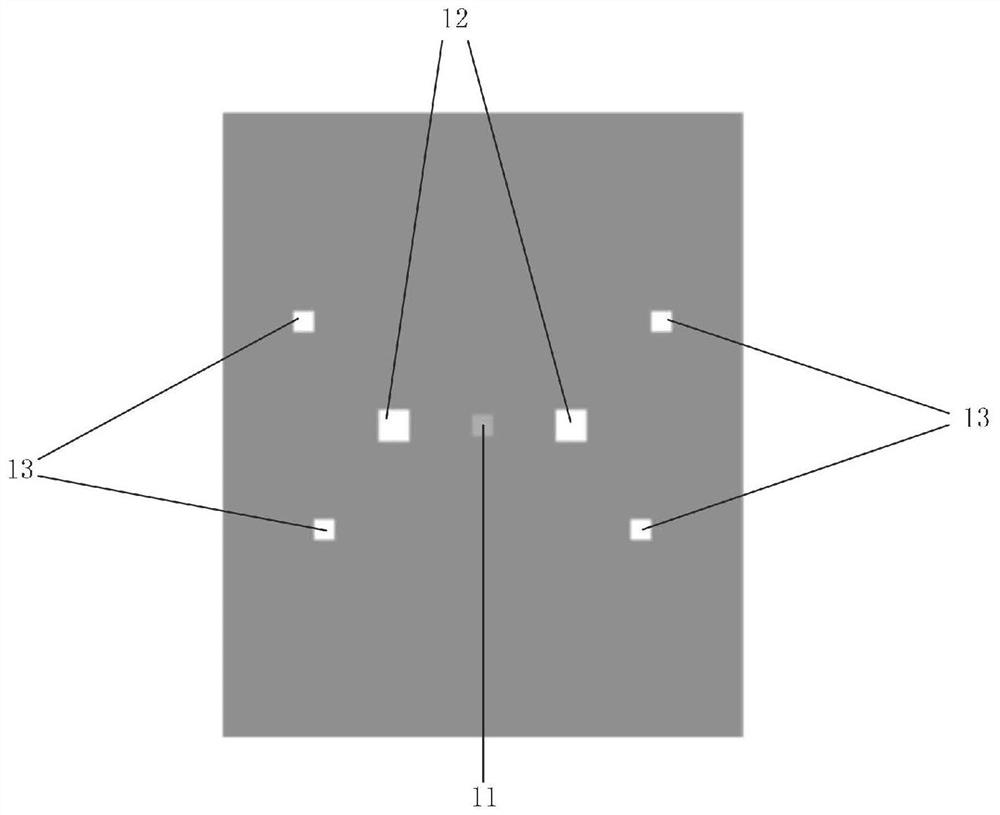

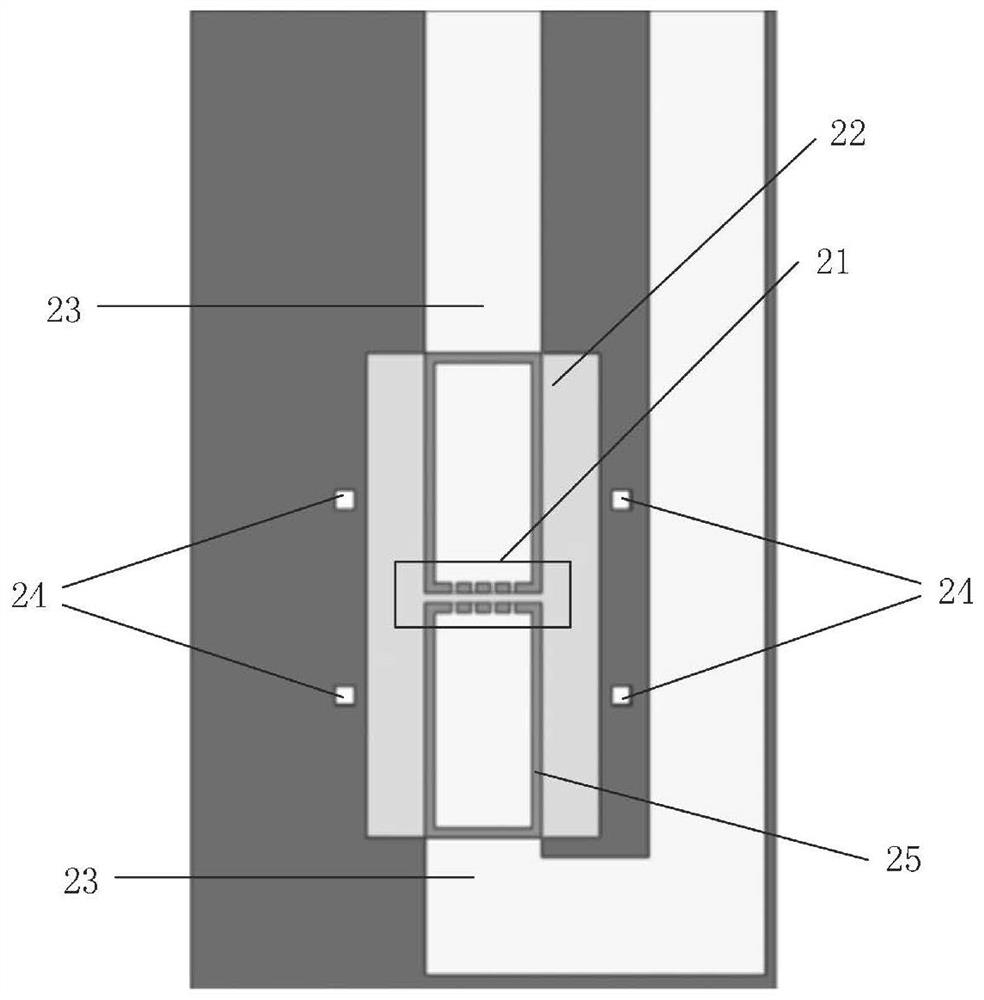

[0017] An in-situ battery device for soft X-ray microscopic imaging provided by an embodiment of the present invention includes:

[0018] An upper silicon wafer (1) and a lower silicon wafer (2); respectively open an upper observation window (11) and a lower observation window (21) on the upper silicon wafer (1) and the lower silicon wafer (2). A liquid injection port (12) is opened on both sides of the observation window (11); a liquid pool (22) is opened on the lower silicon wafer (2), so that the width of the liquid pool (22) is greater than two liquid injection ports (12) Distance between them; 2 electrodes (23) are made on the lower silicon wafer (2), so that one end of the 2 electrodes (23) is relatively placed in the liquid pool (22) and separated by a certain gap, and the gap is located at the upper observation window (11 ) and the area covered by the lower observation window (21), the electrode (23) area in the liquid pool (22) is only left with a single layer of elec...

Embodiment 2

[0026] Due to the small size of the injection port of the upper silicon chip of the in-situ battery in the embodiment of the present invention, the electrolyte needs to be added in a glove box, and the traditional method of first dropping the electrolyte and then aligning the two chips for sealing is no longer necessary Be applicable. In order to facilitate the operation and prevent the silicon wafer from moving, it is necessary to align the upper and lower silicon wafers under the microscope, and then use ultraviolet glue to fix the edges of the connection between the two chips, then remove the silicon wafer from the microscope, and use epoxy resin to completely seal the two silicon wafers. Gap between slices. In the glove box, drop the electrolyte solution at the liquid injection port, completely cover the liquid suction port with a flat syringe with a hose, and slowly pull up the core rod, you can see that the liquid drop at the liquid injection port gradually becomes small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com