Flat plate type target plate for ultrahigh thermal load component of fusion device and processing method of flat plate type target plate

An ultra-high heat, flat-plate technology, used in fusion reactors, thermonuclear fusion reactors, nuclear engineering, etc., can solve problems such as rupture or quenching, insufficient heat transfer capacity, and experiment termination, to ensure heat transfer capacity and avoid functions. Failure, the effect of improving the thermal load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

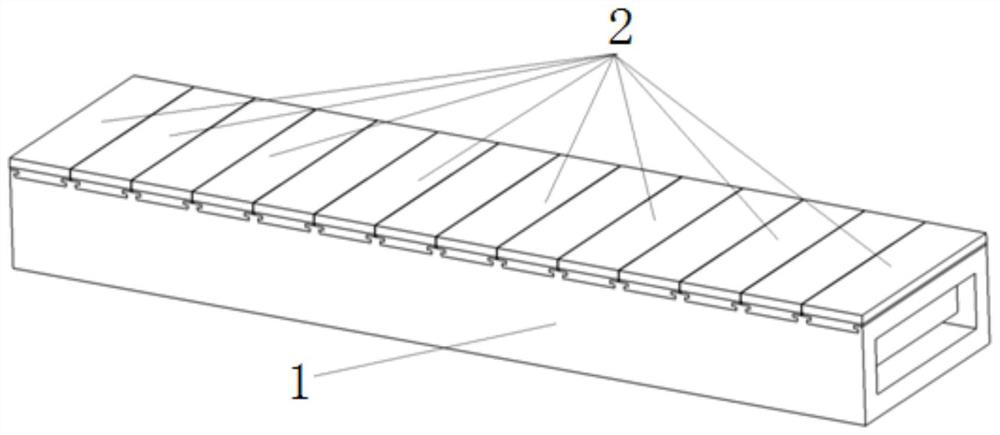

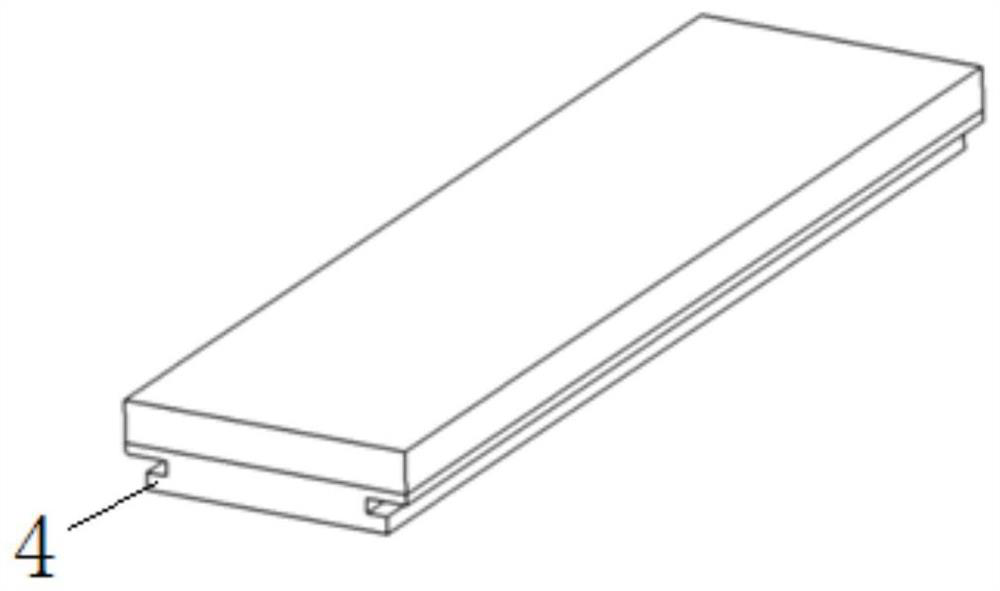

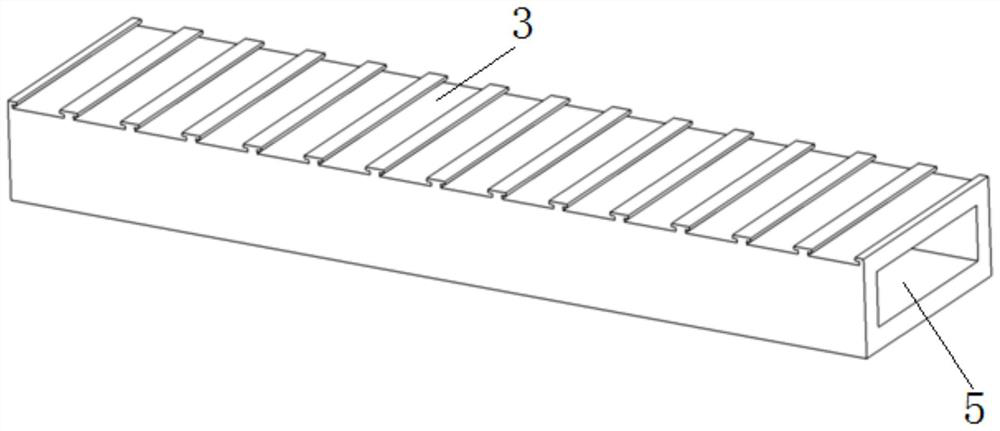

[0033] Such as Figure 1-Figure 3 The shown invention relates to a flat plate target plate for ultra-high thermal load components of a fusion device, including a heat sink 1 and several tungsten copper sheets 2 installed above the heat sink 1 . The number of tungsten copper sheets 2 can be set as required. The first connection part 3 is provided on the heat sink 1, and the second connection part 4 is provided on the tungsten copper sheet 2, and the first connection part 3 and the second connection part 4 are snap-fitted. The heat sink 1 is made of a single material or a composite material, and contains a cooling channel 5 inside, and its main function is to exchange and take away the heat deposited on the components. The tungsten-copper sheet 2 is a composite component composed of tungsten-based materials and copper-based materials through diffusion welding and other methods. Its main function is to withstand the ultra-high thermal load in the fusion test and transfer heat to...

Embodiment 2

[0048] Such as Figure 4-Figure 6 In the illustrated flat plate target plate used for the ultra-high thermal load parts of the fusion device, in this embodiment, the first connecting part is a groove, and the second connecting part is a boss. The longitudinal sections of the connecting part 1 and the connecting part 2 are truncated isosceles triangles. Others are the same as embodiment one.

[0049] The flat plate structure has a higher upper limit of heat load, and it exists in the fusion experimental device as a strike point component, and the main risk of the flat plate component is the shedding of the tungsten copper sheet, which is the reason why the flat plate structure has not been widely used in the world so far , the present invention finds in the test of the flat plate that the tungsten-copper sheet still falls off even after the flow channel is improved. The present invention designs a connection structure with bosses and grooves through improved technology and st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com