Tower type camera structure applied to coaxial four-mirror optical system

An optical system and tower-type technology, which is applied in the field of tower-type camera structures, can solve the problems of not meeting the high rigidity requirements of large-scale space cameras, reducing the thermal stability of camera structures, and the influence of camera optical systems, etc., achieving good athermalization effects and good The effect of structural stability and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0122] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0123] see Figure 1 to Figure 11 shown;

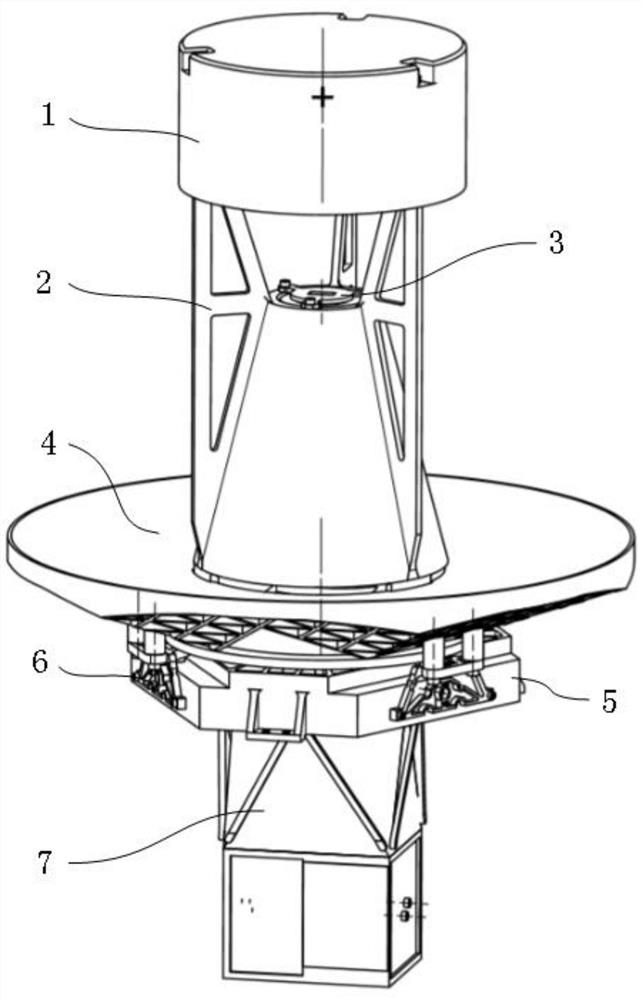

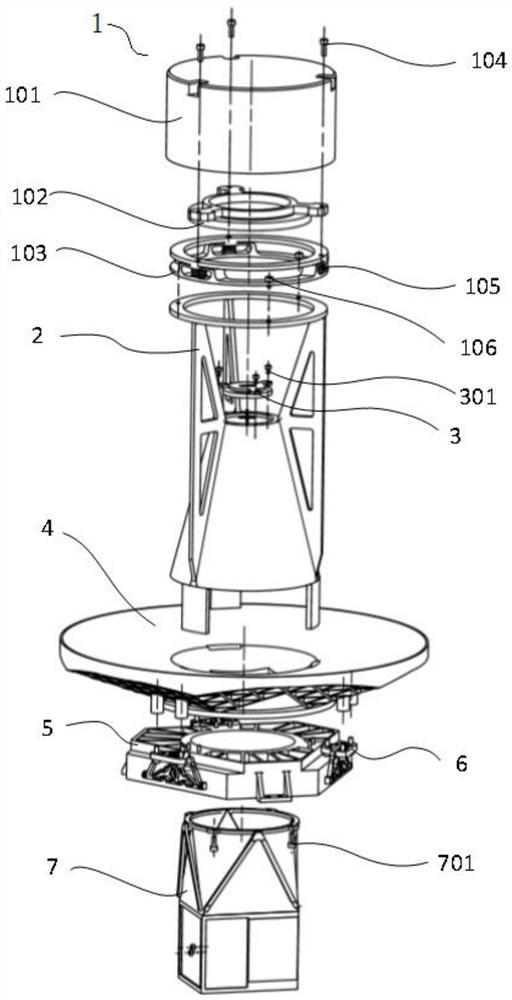

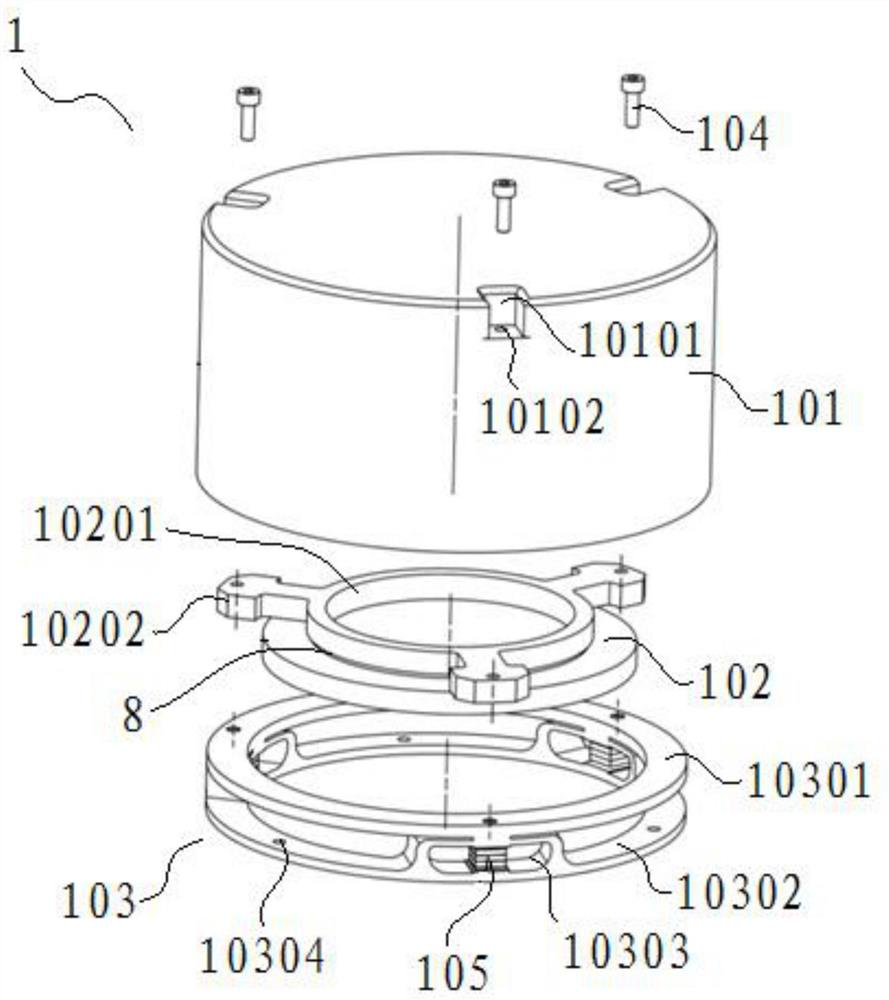

[0124] A tower camera structure applied to a coaxial four-mirror optical system of the present invention, the tower camera structure includes:

[0125] Main three mirrors 4;

[0126] The secondary mirror assembly 1 integrated on the side of the reflecting surface of the primary three mirror 4 through the supporting tower 2;

[0127] The secondary mirror assembly 1 is coaxial with the primary three mirrors 4, and the four mirrors 3 arranged coaxially with the secondary mirror assembly 1 and the primary three mirrors 4 are installed on the supporting tower 2;

[0128] The tower camera structure also includes:

[0129] Substrate 5;

[0130] The substrate 5 is assembled on the back of the main three mirro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com