Paper diaper with side waists capable of being opened and closed and preparation method of paper diaper

A technology of diapers and side waist, which is applied in the field of diapers to achieve the effect of large contact area, simple preparation method and optimized cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] Please refer to Figure 1 to Figure 3 Shown, a kind of preparation method of side waist can open and close paper diaper of the present invention, comprises the following steps:

[0028] Step 1: Stretch the TPU film along its width direction; compound the first non-woven fabric and the second non-woven fabric on both sides of the stretched TPU film, and obtain waist elastic fabric after cutting;

[0029] Step 2. After the magic hook is cut, it is bonded with the waist elastic cloth obtained in step 1 to obtain a semi-finished product of the side waist;

[0030] Step 3. Cutting the semi-finished side waist product obtained in step 2 into individual side waists; performing secondary compounding of the side waist and the upper part of the diaper to obtain a secondary compounded semi-finished product;

[0031] Step 4. After the core body is cut, the secondary composite semi-finished product obtained in step 3 and the bottom layer of the diaper are integrally composited and ...

Embodiment 1

[0050] A method for preparing a paper diaper with an openable side waist, specifically comprising the following steps;

[0051] Step 1: Stretch the TPU film with a thickness of 0.025mm and a width of 200mm along its width direction; compound the first non-woven fabric and the second non-woven fabric on both sides of the stretched TPU film, and cut it to obtain a waist elastic fabric ;

[0052] Step 2. After the magic hook is cut, it is bonded with the waist elastic cloth obtained in step 1 to obtain a semi-finished product of the side waist;

[0053] Step 3, the semi-finished product of the side waist obtained in step 2 is arc-cut and sectioned to form a continuous side waist, and then the continuous side waist is divided into individual sides;

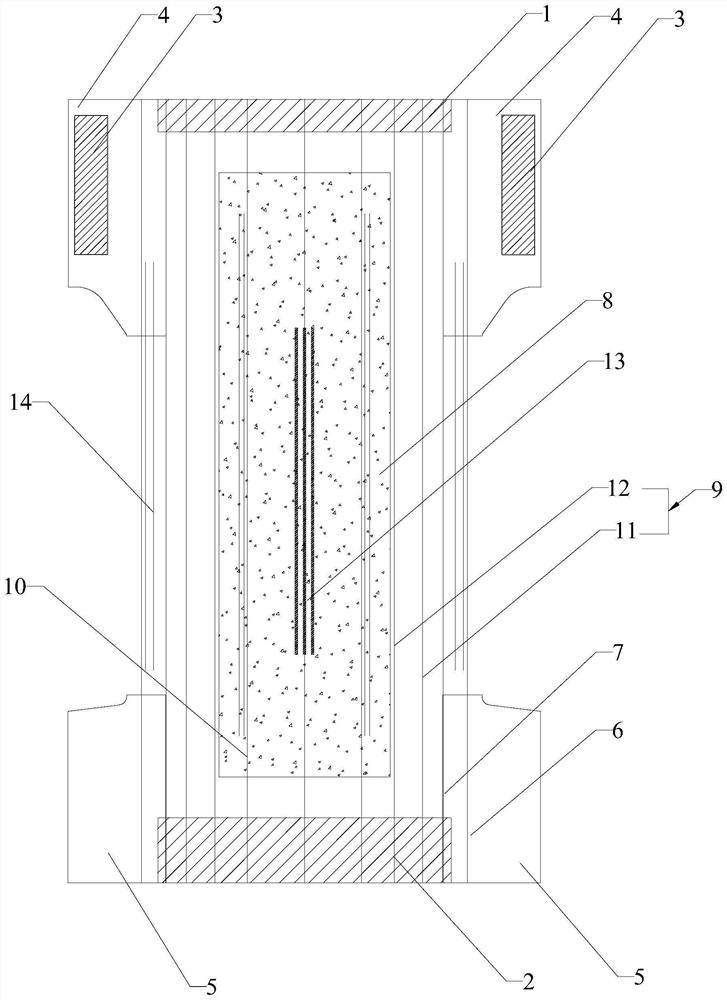

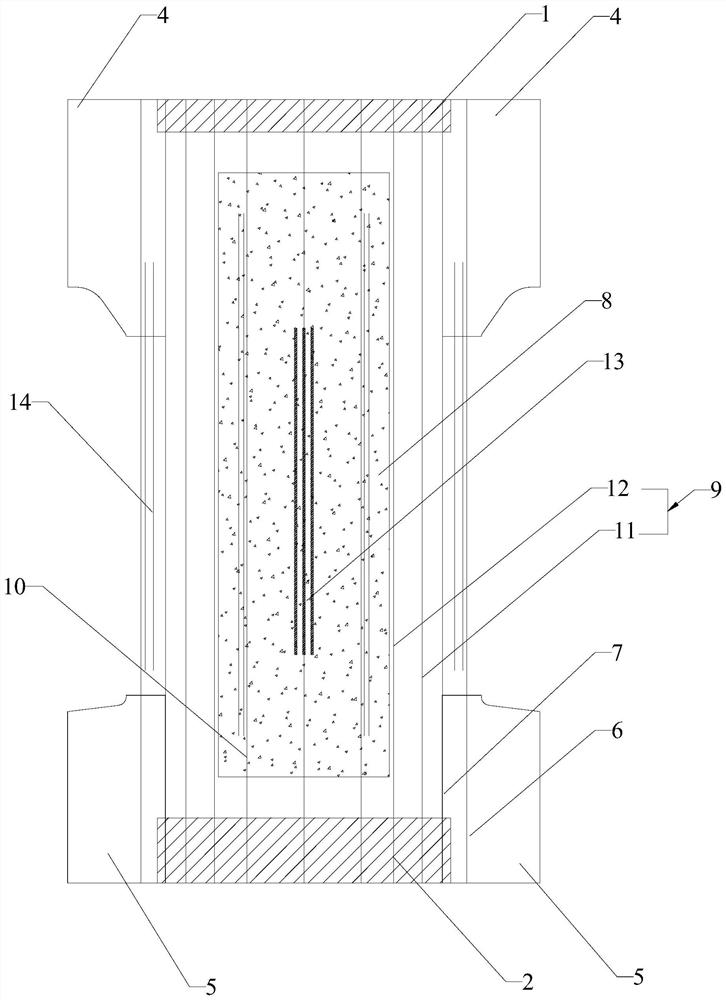

[0054] Step 4. Ultrasonically press the upper non-woven fabric 11 and the lower non-woven fabric 12 into 3D lines to obtain the surface layer non-woven fabric 9, and the leak-proof enclosure 10 obtained by compounding the protective ...

Embodiment 2

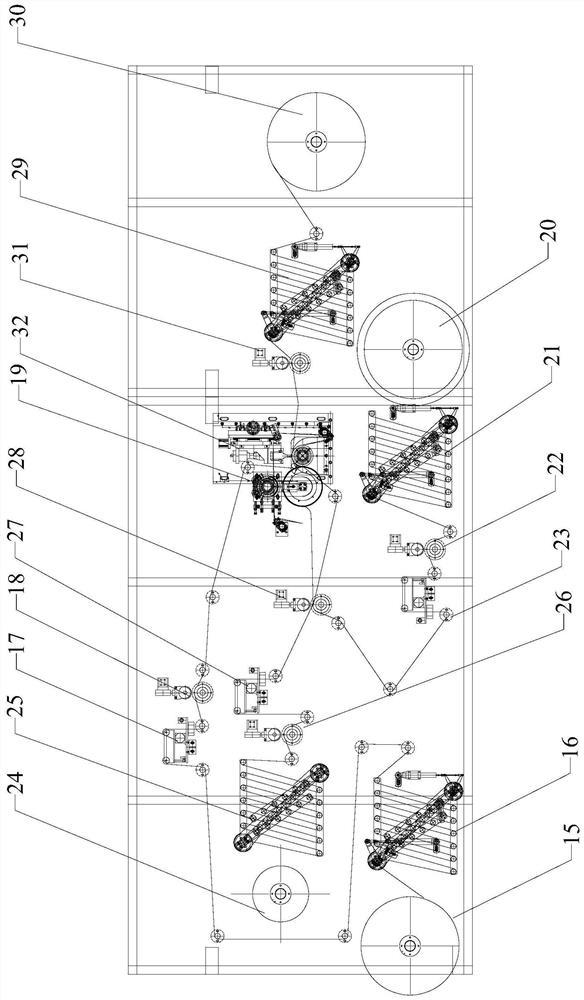

[0060] The preparation device for preparing waist elastic cloth according to Embodiment 1 of the present invention comprises a frame and a first mechanism, a second mechanism, a third mechanism and a fourth mechanism arranged on the frame:

[0061] The discharge ends of the first mechanism, the second mechanism and the third mechanism are respectively connected to the feed end of the fourth mechanism;

[0062] The first mechanism includes a first uncoiling air shaft 15, a first tension swing rod 16, a first deviation corrector 17, and a first pair of pressure rollers 18 arranged in an assembly line;

[0063] The second mechanism includes a second uncoiling air shaft 20 arranged in an assembly line, a second tension swing rod 21, a second pair of pressure rollers 22, and a second deviation corrector 23;

[0064] The third mechanism includes a third uncoiling air shaft 24, a third tension swing bar 25, a third counter-pressure roller 26, a third deviation corrector 27, and a fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com