Full-automatic supercritical drying instrument

A supercritical drying, fully automatic technology, applied in the direction of drying gas arrangement, drying, dryer, etc., can solve the problems of long experimental period, difficult safety and low output of supercritical drying process, and achieve convenient drying process. Fast, time- and labor-cost savings, and improved cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

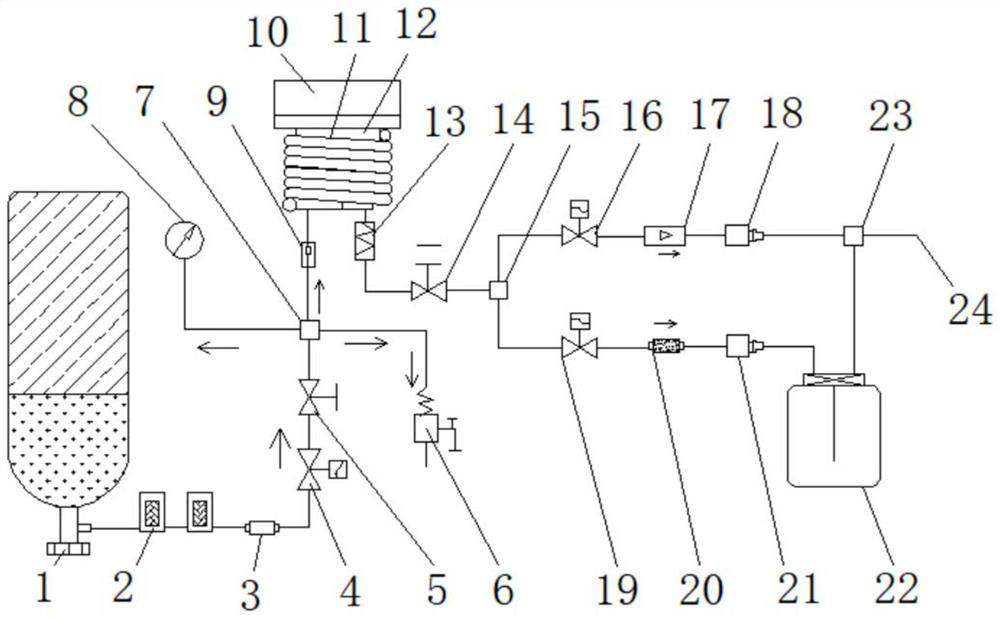

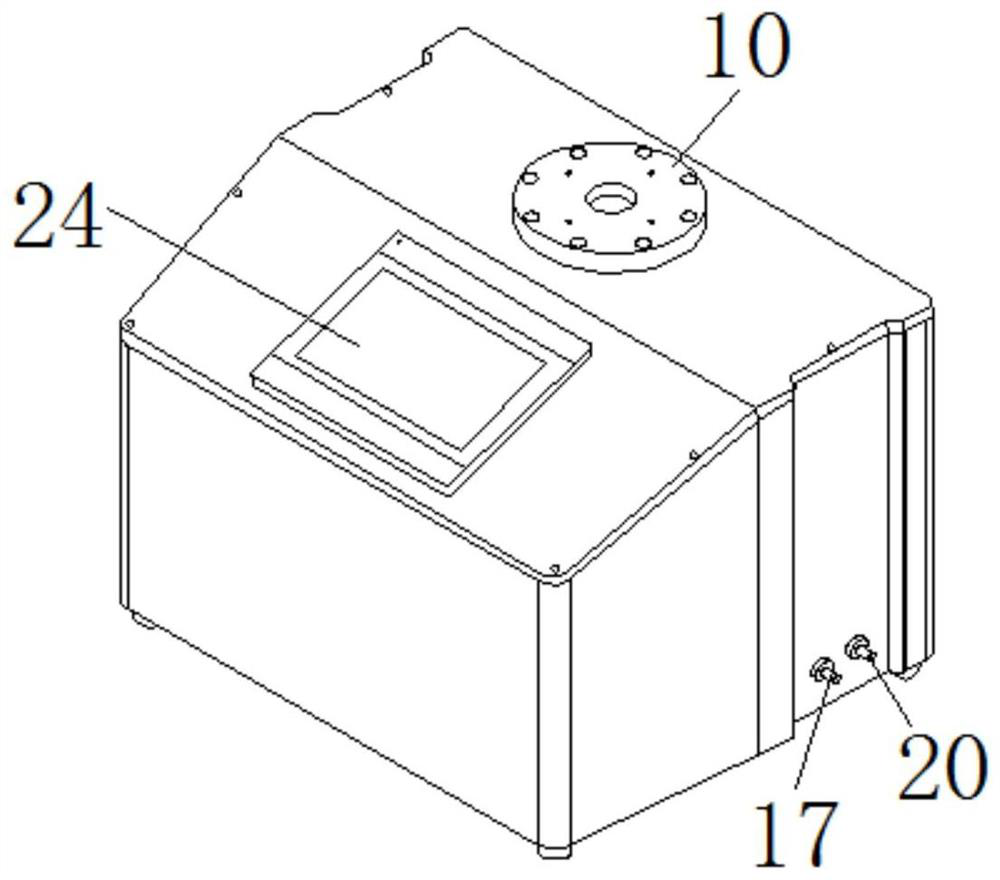

[0037] Example 1, such as figure 1 and 2 As shown, when drying a sample, the power is first turned on, and then the user puts the sample to be dried into the high-pressure sample cell 10, and at the same time adds the liquid solvent required to maintain the sample structure, closes the high-pressure sample cell cover and locks it effectively. Tight, and set the parameters required for the drying experiment on the touch software interface of the fully automatic touch LCD screen 24. After the setting is completed, directly click to run. At this time, the gas inside the supercritical fluid gas source 1 passes through the high-precision filter A2, Ultra-high-precision filter 3, liquid inlet high-pressure solenoid valve 4 and liquid inlet automatic fine-tuning valve 5, the liquid inlet automatic fine-tuning valve 5 can decompress the air flow to ensure the pressure in the high-pressure sample cell rises steadily and slowly, and then the air flow passes through the four-way joint 7...

Embodiment 2

[0038] Example 2, such as figure 1 and 2 As shown, when the air pressure temperature is high, the refrigeration module 11 and the heating module 12 start to control the temperature inside the high-pressure sample cell 10, so that the supercritical fluid reaches the temperature required for the supercritical state, and then the airflow passes through the high-precision filter B13 and the micro-flow adjustment module 14 enter the tee joint A15, at this time, the gas passes through the high-pressure solenoid valve A16, the electronic flow sensor 17, the exhaust through-plate interface 18 and the tee joint B23, and then is discharged outside or the laboratory fume hood. The liquid enters the designated anti-corrosion gas-liquid separation bottle 22 through the high-pressure solenoid valve B19, high-precision filter C20 and liquid discharge through-plate interface 21, and the anti-corrosion gas-liquid separation bottle 22 fully separates the residual gas in the liquid again, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com