Technical process for treating sewage generated by chemical treatment of animals died of illness

A technology for the treatment of dead animals and sewage. It is applied in the field of sewage treatment of dead animals. It can solve the problems of substandard effluent quality of COD and ammonia nitrogen, unstable water quality components, and difficult water quality treatment. The effect of the reaction cycle and the improvement of sewage treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

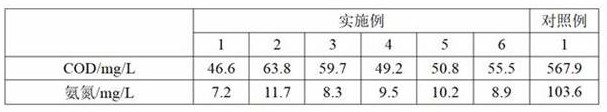

Examples

Embodiment 1

[0018] A technological process for treating sick and dead animal sewage, the treatment process comprising the following steps:

[0019] (1) Pretreatment separation process

[0020] Cool the sewage in the sewage tank of sick and dead animals to 35°C, seal and heat-preserve the deep water anaerobic stirring for 24 hours, the sewage is separated by a tube-bundle centrifuge, and the solid phase is returned to the crusher; the liquid phase is kept at 35°C through a microflow reactor Anaerobic reaction for 90 minutes, the sewage is centrifuged by a three-phase horizontal centrifuge, and the solid phase is returned to the crusher; after the liquid phase and activated microorganisms are mixed evenly, the aerobic reaction temperature is controlled at 40°C for 56 hours of biochemical reaction, and the sewage is passed through three After centrifugation in a horizontal centrifuge, the solid phase is returned to the temporary storage tank for activated microorganisms, and the liquid phase...

Embodiment 2

[0026] A technological process for treating sick and dead animal sewage, the treatment process comprising the following steps:

[0027] (1) Pretreatment separation process

[0028] Cool the sewage in the sewage tank of sick and dead animals to 30°C, seal and heat-preserve the deep-water anaerobic stirring for 24 hours, the sewage is separated by a tube-bundle centrifuge, and the solid phase is returned to the crusher; the liquid phase is kept at 30°C through a microflow reactor Anaerobic reaction for 180 minutes, the sewage is centrifuged by a three-phase horizontal centrifuge, and the solid phase is returned to the crusher; after the liquid phase and activated microorganisms are mixed evenly, the aerobic reaction temperature is controlled at 35°C for 72 hours of biochemical reaction, and the sewage is passed through three After centrifugation in a horizontal centrifuge, the solid phase is returned to the temporary storage tank for activated microorganisms, and the liquid phas...

Embodiment 3

[0034] A technological process for treating sick and dead animal sewage, the treatment process comprising the following steps:

[0035] (1) Pretreatment separation process

[0036] Cool the sewage in the sewage tank of sick and dead animals to 45°C, seal and heat-preserve the deep-water anaerobic stirring for 24 hours, the sewage is separated by a tube-bundle centrifuge, and the solid phase returns to the crusher; the liquid phase is kept at 45°C through a microflow reactor Anaerobic reaction for 15 minutes, the sewage is centrifuged by a three-phase horizontal centrifuge, and the solid phase is returned to the crusher; after the liquid phase and activated microorganisms are mixed evenly, the aerobic reaction temperature is controlled at 58 ° C for 72 hours of biochemical reaction, and the sewage is passed through three After centrifugation in a horizontal centrifuge, the solid phase is returned to the temporary storage tank for activated microorganisms, and the liquid phase i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com