Artificial unfired solid core ceramsite, ceramsite concrete and preparation method thereof

A ceramsite concrete and concrete technology, applied in the field of building materials, can solve problems such as troublesome processing of recycled aggregates, and achieve the effects of improving strength, improving pumping efficiency, and increasing fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

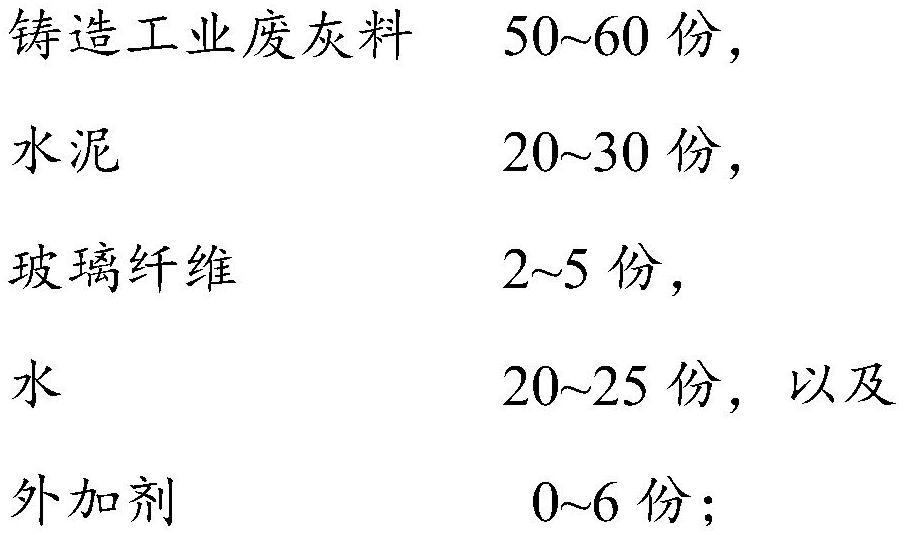

Method used

Image

Examples

Embodiment 1

[0037] This embodiment provides a kind of artificial fire-free solid core ceramsite, and its raw material composition is shown in the following table:

[0038] raw material name Dosage (parts) foundry waste ash 52 cement 28 glass fiber 3.5 VAE rubber powder 1.8 Superplasticizer 0.24 early strength agent 0.32 water 24.8

[0039] The preparation method of the artificial fire-free solid core ceramsite of the present embodiment comprises the steps:

[0040]S1. Put water, VAE rubber powder, water reducer and early strength agent in a liquid mixer according to the formula in the above table, and stir at a speed of 20-50 R / min for 15 minutes to prepare a mixed solution, and then mix it at 2-5 R / min Stir continuously at high speed for later use.

[0041] S2, according to the formula in the above table, put foundry industrial waste ash, cement and glass fiber in a solid mixer, stir at a speed of 100-150 R / min for 5 minutes, then...

Embodiment 2

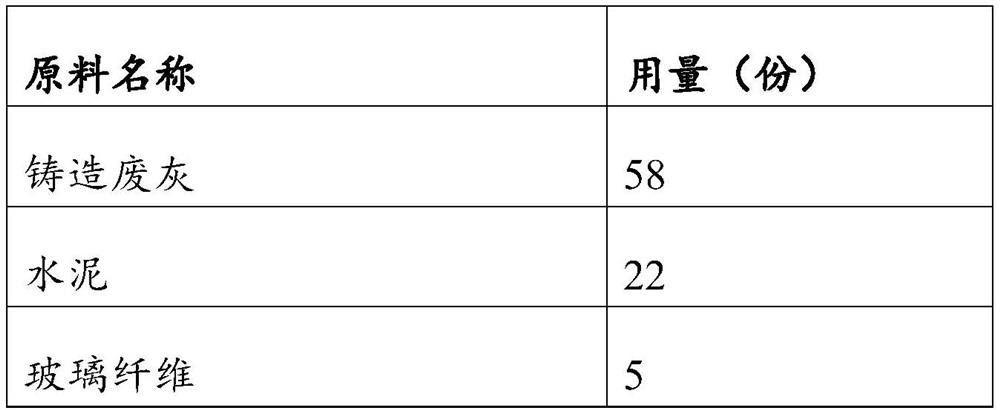

[0044] This embodiment provides a kind of artificial fire-free solid core ceramsite whose raw material composition is shown in the following table:

[0045]

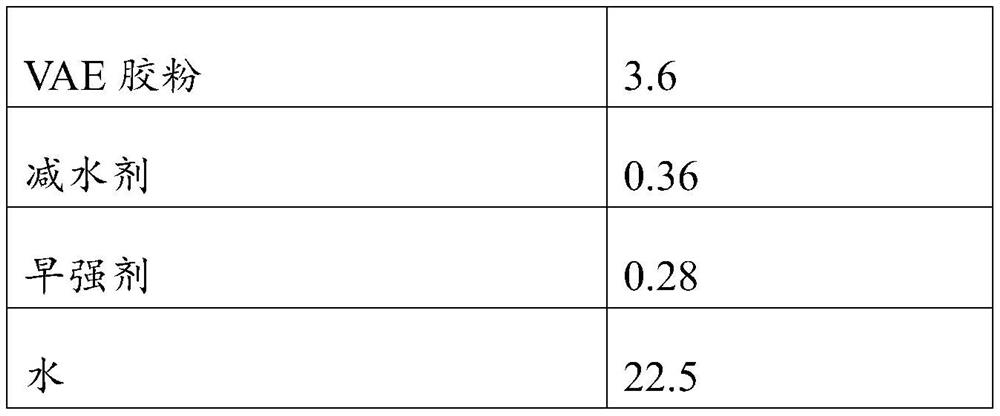

[0046]

[0047] The preparation method of the artificial fire-free solid core ceramsite in this embodiment is basically the same as that in Embodiment 1.

Embodiment 3

[0049] This embodiment provides a kind of ceramsite concrete, and its raw material composition is shown in the following table:

[0050] raw material name Dosage (parts) cement 7.8 fly ash 3.2 water 4 Superplasticizer 0.24 The artificial fire-free solid core ceramsite (5~20mm) prepared in embodiment 1 24 Medium stone aggregate (20~35mm) 32 river sand 9 Machine-made sand 17.5

[0051] The preparation method of present embodiment ceramsite concrete comprises the steps:

[0052] S1, according to the amount in the above table, weigh the artificial non-fired solid core ceramsite (5-20mm), Zhongshi aggregate, river sand and machine-made sand prepared in Example 1, and add them to the mixing equipment, at a speed of 100-200R / min Stir for 2-5 minutes to obtain the first mixture.

[0053] S2. Add cement and fly ash to the first mixture in step S1 according to the dosage in the above table, and stir at 100-200 R / min for 2-5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com