Processing aid for thermoplastic polymer and melt-processable composition containing same

A technology for thermoplastic polymers and processing aids, applied in the field of processing aids for thermoplastic polymers and melt-processable compositions, can solve the problems of performance degradation and cost reduction of processing aids, achieve cost reduction and improve use effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

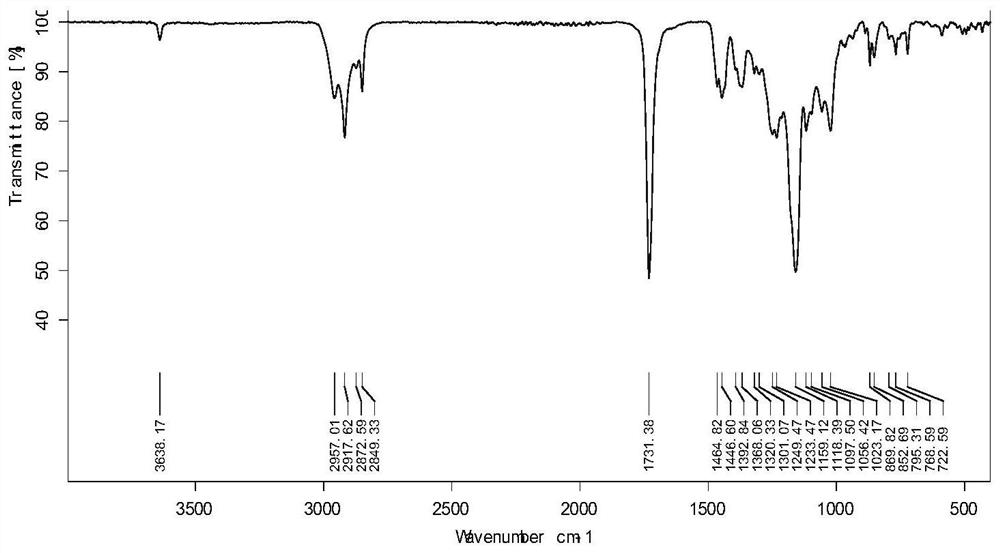

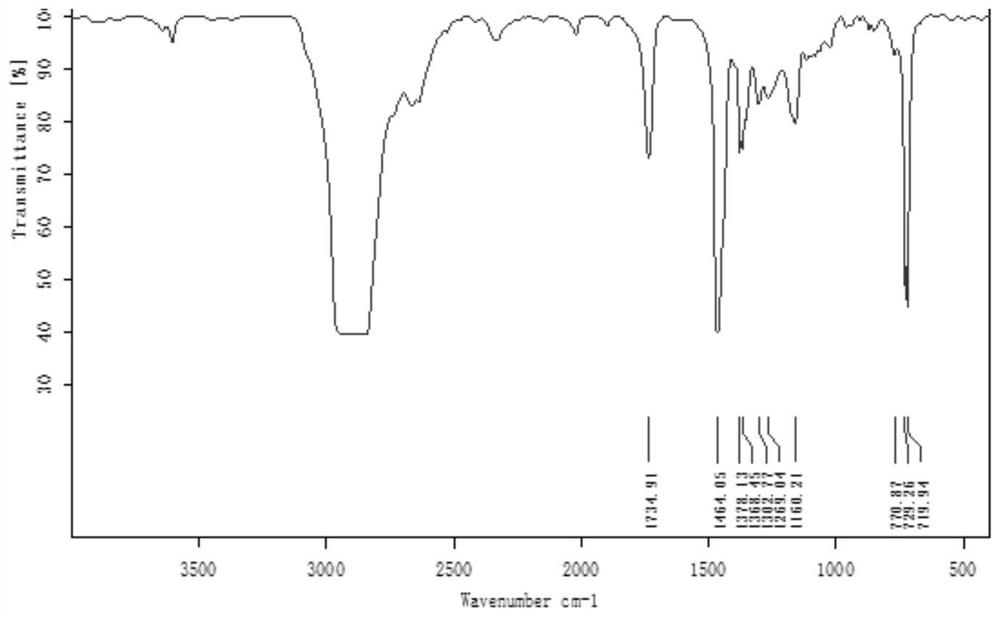

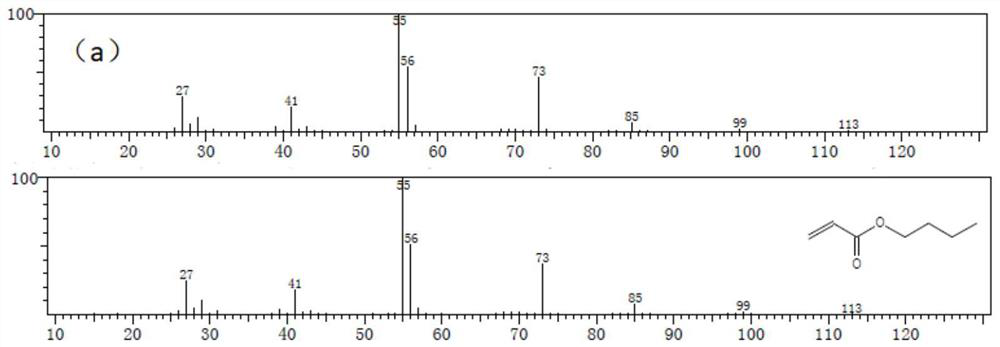

Method used

Image

Examples

Embodiment 1

[0047] Preparation and use of processing aid for embodiment 1PPA-1 thermoplastic polymer

[0048] (1) In a container with stirring and mixing, add 56.5 parts (weight) of ethyl acrylate, 33.5 parts (weight) of butyl acrylate, 10 parts (weight) of acrylic acid and 0.01 part (weight) of positive Dodecanethiol, stirred evenly to obtain a monomer mixture;

[0049] Then in the reactor with heating and stirring device, add the water of 400 parts (weight), the sodium stearate of 0.6 part (weight) and the potassium persulfate of 0.04 part (weight), after stirring and being heated to 65 ℃, in Add the above-obtained monomer mixture into the reactor uniformly and continuously within 2-3 hours, keep the temperature for 0.5 hours and then lower the temperature to 30° C. to obtain a polyacrylate emulsion. Sampling detects that the particle diameter of the latex is 127nm, and the solid content is 20%. The weight-average molecular weight of the polyacrylate is 1.34 million as measured by the ...

Embodiment 2

[0053] Preparation and use of processing aid for embodiment 2PPA-2 thermoplastic polymer

[0054] (1) In a container with stirring and mixing, add 56.5 parts (weight) of ethyl acrylate, 33.5 parts (weight) of butyl acrylate, 10 parts (weight) of acrylic acid and 0.07 parts (weight) of positive Dodecanethiol, stirred evenly to obtain a monomer mixture.

[0055] Then in the reactor with heating and stirring device, add the water of 400 parts (weight), the sodium stearate of 0.6 part (weight) and the potassium persulfate of 0.05 part (weight), after stirring and being heated to 65 ℃, in Add the monomer mixture obtained above to the reactor uniformly and continuously within 2-3 hours, keep the temperature for 0.5 hours and then lower the temperature to 30° C. to obtain a polyacrylate emulsion. The particle size of the latex was 102nm and the solid content was 20% as detected by sampling. The weight average molecular weight of the polyacrylate measured by GPC was 560,000.

[0056...

Embodiment 3

[0059] Preparation and use of processing aid for embodiment 3PPA-3 thermoplastic polymer

[0060] Get 30 parts of (weight) the PPA-1 that obtains in the embodiment 1 and join in the disperser, then add 70 parts of (weight) molecular weight again and be the Polyethylene Glycol of 10000, obtain fluorine-containing polymer content 10% after mixing, A processing aid for thermoplastic polymers containing 20% polyalkyl acrylate elastomer and 70% polyethylene glycol is denoted as PPA-3.

[0061] Preparation of melt processable composition: 3 parts (weight) of PPA-3 and 97 parts (weight) of thermoplastic polyolefin resin LLDPE are first mixed uniformly, then continuously fed into twin-screw extruder, under the condition of 190 ° C , extruded strands, cooled and solidified in a water bath, pelletized and dried to obtain a processing aid masterbatch with a PPA-3 content of 3%, denoted as MB-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com