Sealed sample pool for laser high-temperature molten carbonate sample and use method thereof

A technology of high-temperature melting and sample pool, which is applied in the direction of material analysis, instruments, and measuring devices through optical means. It can solve the problems of good reproducibility, gas leakage, and reproducibility of cover falling off and falling to the ground. Good performance, avoid the incorporation of air, and ensure the fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

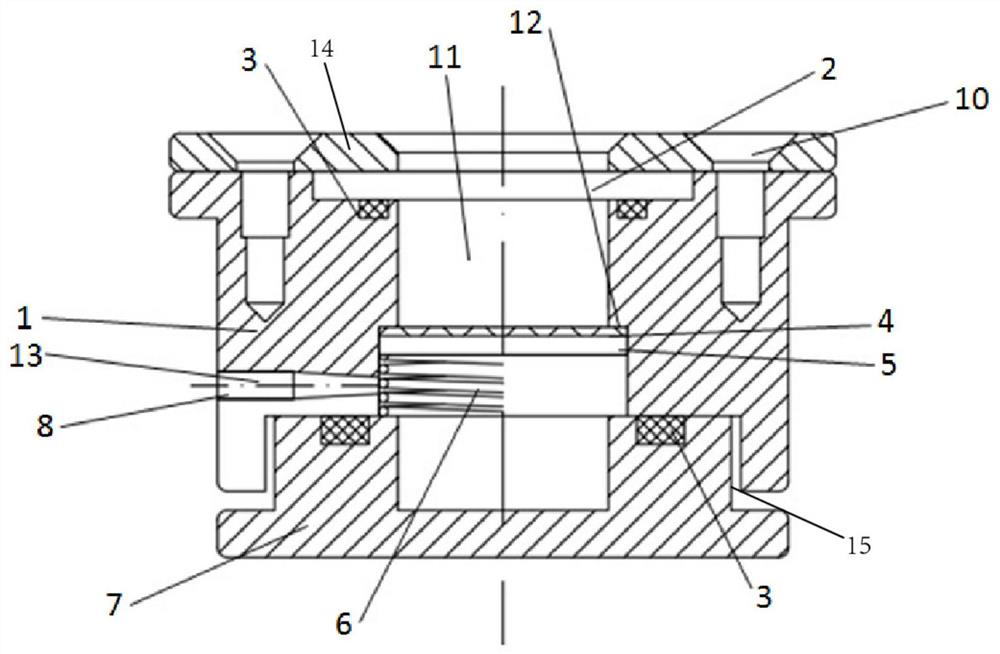

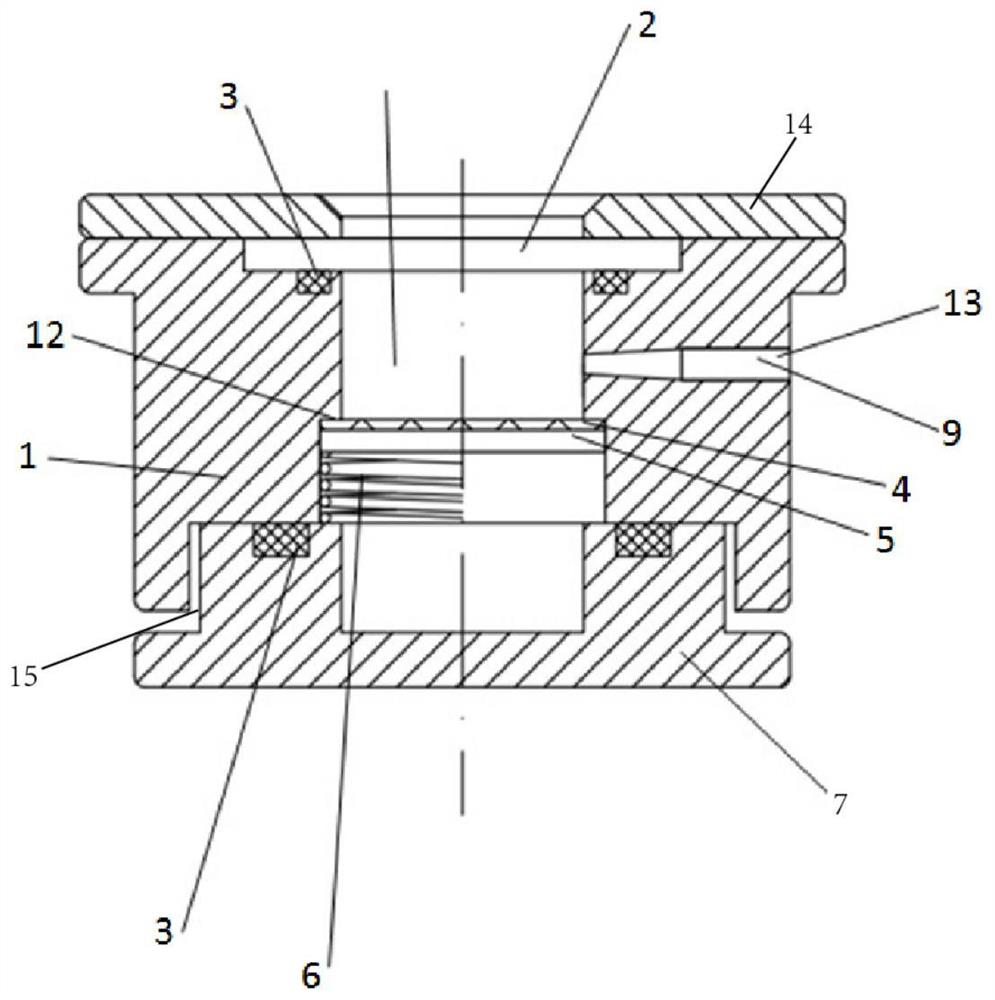

[0024] A sealed sample cell for laser high-temperature molten carbonate samples, including a sample cell upper seat 1 and a sample cell base 7, a sealed slot is formed on the lower surface of the sample cell upper seat 1, and the sample cell base 7 adopts a "convex" shape structure, the tail end of the upper seat 1 of the sample cell is inserted into the head end of the base 7 of the sample cell to achieve the purpose of sealing. The center hole of the step on the upper seat of the pool, the center counterbore is connected with the center hole of the step to form a sealed cavity 11, the center hole of the step is composed of a sample placement hole and a sealing hole, and a sample limiting hole is formed at the connection between the sample placement hole and the sealing hole Step 12, the sample 4 is set at the sample limit step 12, and a support assembly is arranged between the lower surface of the sample 4 and the upper surface of the sample cell base 7 for supporting the sam...

Embodiment 2

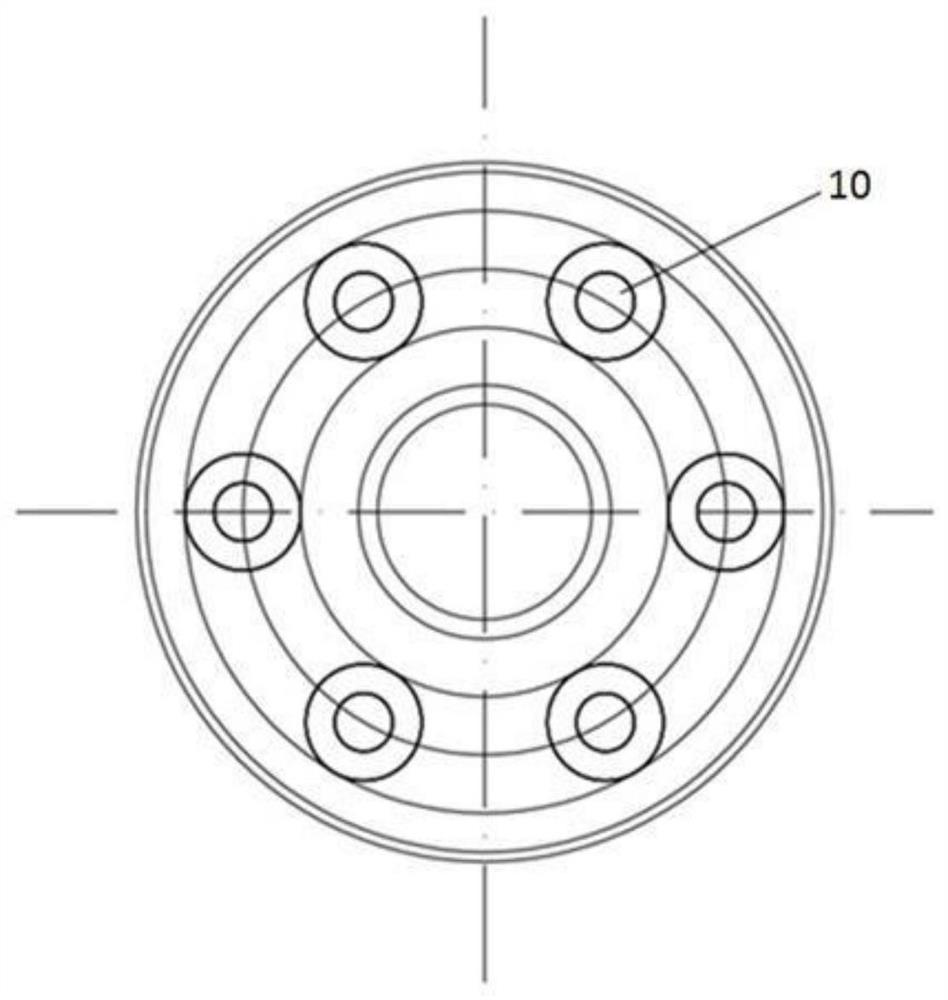

[0026] On the basis of Embodiment 1, a fixed cover 14 is also provided on the upper surface of the sample cell upper seat 1, and a fixed through hole is formed at the center of the fixed cover 14, and the fixed through hole is arranged opposite to the sealing hole, so that the laser beam can After passing through the fixed through hole-zinc sulfide window mirror 2, it is injected into the sealed cavity 11.

[0027] Fixed screw holes are provided on the fixed cover 14 on both sides of the fixed through hole, and screw holes are provided at corresponding positions on the upper surface of the sample cell upper base 1. After fixing the screw holes and the screw holes, the fixing cover 14 is fixed on the upper surface of the sample cell upper base 1, thereby realizing the purpose of fixing the zinc sulfide window mirror 2 in the window mirror placement groove.

[0028] A window mirror sealing groove is provided on the upper surface of the window mirror placement groove, a sealing g...

Embodiment 3

[0030] On the basis of Embodiment 2, an external thread 15 is formed on the outer wall of the protruding part of the sample cell base 7, and an internal thread is formed on the side wall of the sealing groove, and the sample cell base 7 is connected to the upper seat of the sample cell through the external thread. 1 internal thread thread connection.

[0031] A ferrule interface 13 is formed in both the air inlet 8 and the air outlet 9, so as to communicate with the pipeline.

[0032] The size of the ferrule interface 13 is 1 / 16 inch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com