Acetone sensor, preparation method and application

A sensor and gas sensor technology, applied in the field of gas sensor preparation, can solve the problems of cumbersome synthesis process and high template cost, and achieve the effects of improving specific surface area and sensitivity, avoiding template cost, and excellent sensitivity characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

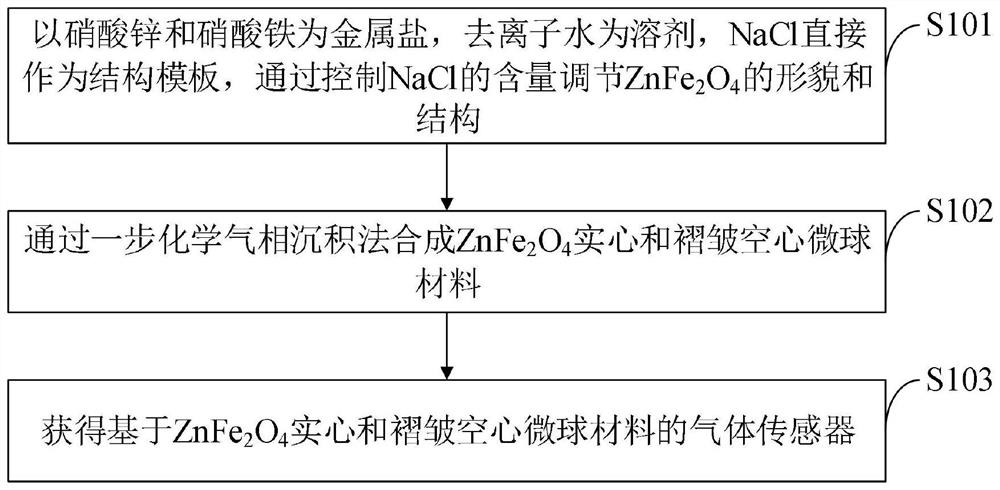

[0043] Such as figure 1 As shown, the preparation method of the acetone sensor provided by the embodiment of the present invention comprises the following steps:

[0044] S101, using zinc nitrate and iron nitrate as metal salts, deionized water as solvent, NaCl directly as a structural template, and adjusting ZnFe by controlling the content of NaCl 2 o 4 shape and structure;

[0045] S102, Synthesis of ZnFe by one-step chemical vapor deposition 2 o 4 Solid and pleated hollow microsphere materials;

[0046] S103, obtained based on ZnFe 2 o 4 Gas sensors of solid and pleated hollow microsphere materials.

Embodiment 1

[0049] The preparation method and application of the acetone sensor based on the green NaCl template provided by the embodiment of the present invention include the following steps:

[0050] (1) Zinc nitrate and ferric nitrate are used as metal salts, deionized water is used as solvent, and NaCl is directly used as a green, pollution-free and easy-to-remove structural template, and the ZnFe is effectively adjusted by controlling the content of NaCl. 2 o 4 shape and structure;

[0051] (2) Synthesize ZnFe with ZnFe by one-step chemical vapor deposition 2 o 4 Solid and pleated hollow microsphere materials;

[0052] (3) Obtained based on ZnFe 2 o 4 Gas sensors of solid and wrinkled hollow microsphere materials and their application to acetone detection.

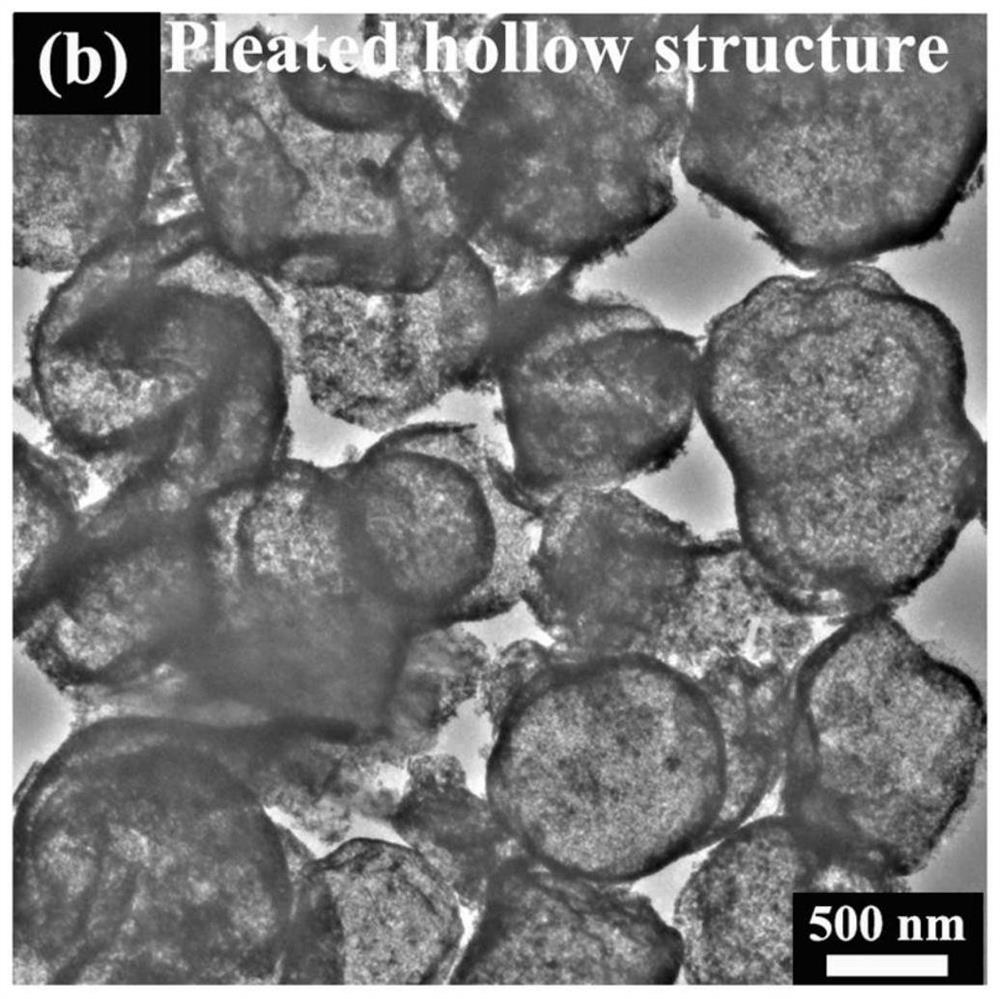

[0053] ZnFe of the present invention 2 o 4 The content of chemical reagents in the preparation process of the wrinkled hollow microsphere gas-sensing material is 3mmol and 6mmol of zinc nitrate and ferric nitrate respect...

Embodiment 2

[0071] The preparation method and application of the acetone sensor based on the green NaCl template provided by the embodiment of the present invention include the following steps:

[0072] (1) Zinc nitrate and ferric nitrate are used as metal salts, deionized water is used as solvent, NaCl is directly used as a green, pollution-free and easy-to-remove structural template, and ZnFe is effectively regulated by controlling the content of NaCl. 2 o 4 shape and structure;

[0073] (2) Synthesize ZnFe with ZnFe by one-step chemical vapor deposition 2 o 4 Solid and pleated hollow microsphere materials;

[0074] (3) Obtained based on ZnFe 2 o 4 Gas sensors of solid and wrinkled hollow microsphere materials and their application to acetone detection.

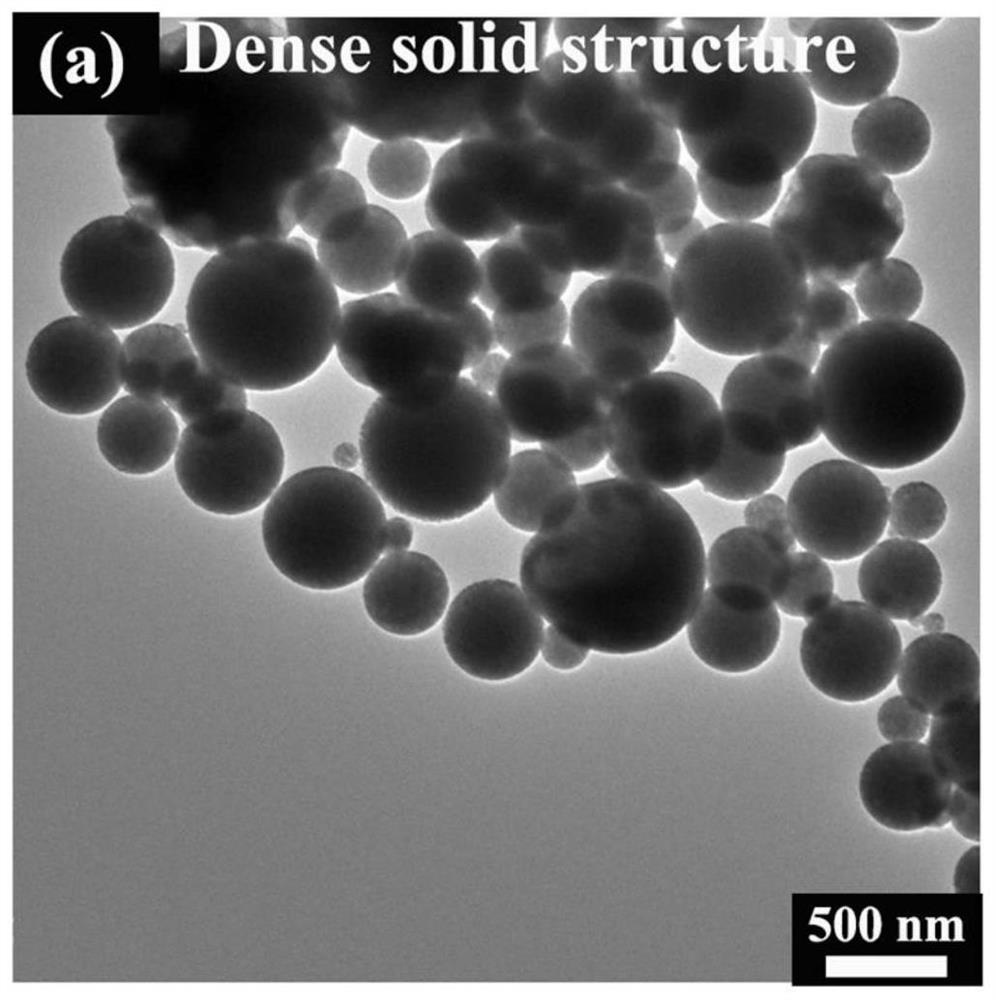

[0075] ZnFe of the present invention 2 o 4 The content of chemical reagents in the preparation process of the solid microsphere gas-sensing material is 3mmol and 6mmol of zinc nitrate and ferric nitrate respectively; the conten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com