Super-thick aluminum alloy quenched plate and preparation method thereof

An aluminum alloy, ultra-thick technology, applied in the field of aluminum alloy, can solve the problems of large difference in performance between surface and core, immature production process, gap in production level, etc., achieve small deformation, eliminate ingot composition segregation, water quenching fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

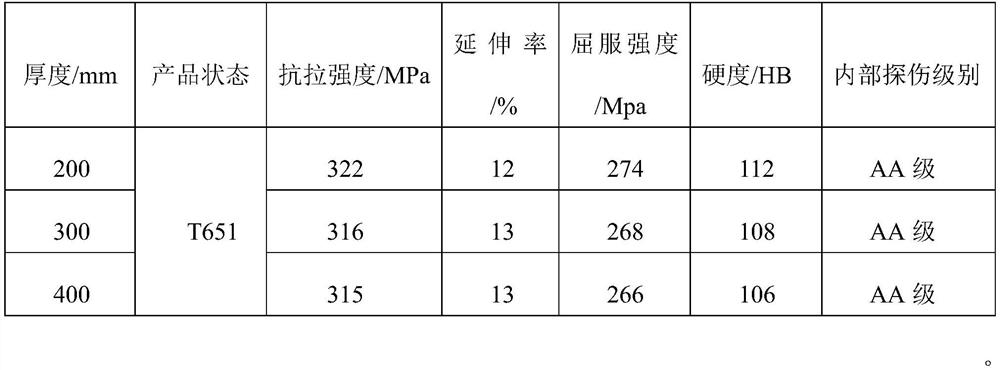

Examples

Embodiment 1

[0034]The present invention is an ultra-thick aluminum alloy quenching plate, expressed in terms of mass percentage content, the super-thick aluminum alloy quenching plate in each alloy element and its content is Si 0.2%, Fe 0.16%, Cu 0.24%, Mn 0.005%, Mg 1.1%, Cr 0.21%, Zn0.007%, Ti 0.02%, the margin is Al.

Embodiment 2

[0036] The present invention is an ultra-thick aluminum alloy quenching plate, expressed in terms of mass percentage content, the super thick aluminum alloy quenching plate in each alloy element and its content is Si 0.21%, Fe 0.25%, Cu 0.26%, Mn 0.008%, Mg 1.13%, Cr 0.21%, Zn 0.008%, Ti 0.025%, the residual amount is Al.

Embodiment 3

[0038] The ultra-thick aluminum alloy quenching plate of the present invention, expressed in terms of mass percentage content, the super-thick aluminum alloy quenching plate in each alloy element and its content is Si 0.23%, Fe 0.17%, Cu 0.25%, Mn 0.009%, Mg 1.13%, Cr 0.22%, Zn 0.006%, Ti 0.026%, the residual amount is Al.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com