Cutter for machining straight bevel gear

A technology of straight bevel gears and cutting tools, which is applied in the direction of gear tooth manufacturing tools, manufacturing tools, components with teeth, etc., can solve the problems of insufficient machining accuracy, low production efficiency, fast wear, etc. Threshold, cutting line speed increase, the effect of increasing cutting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The gear ratio of a pair of bevel gears is 20:21, the big end modulus is 1mm, the pressure angle is 20 degrees, the tooth width is 5mm, the addendum height coefficient is 1, and the head clearance coefficient is 0.2. This embodiment provides a tool for machining large gears, which is used for semi-finishing of the soft tooth surface of straight bevel gears, finishing of workpieces and removal of burrs.

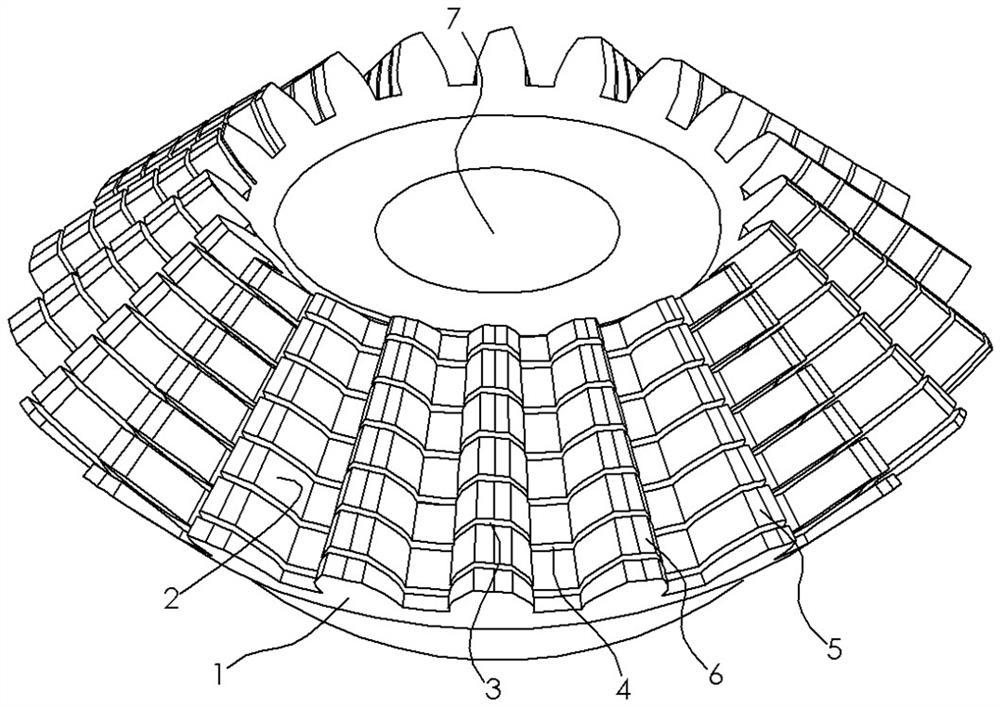

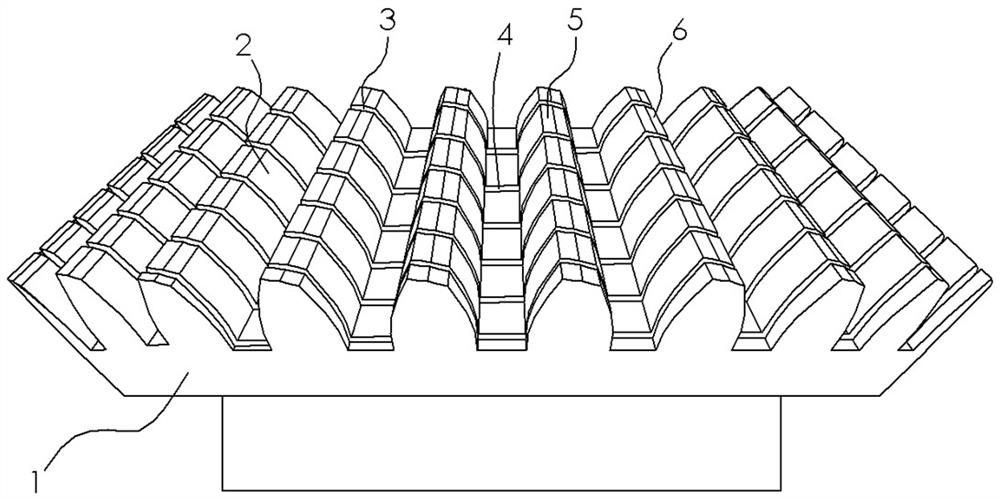

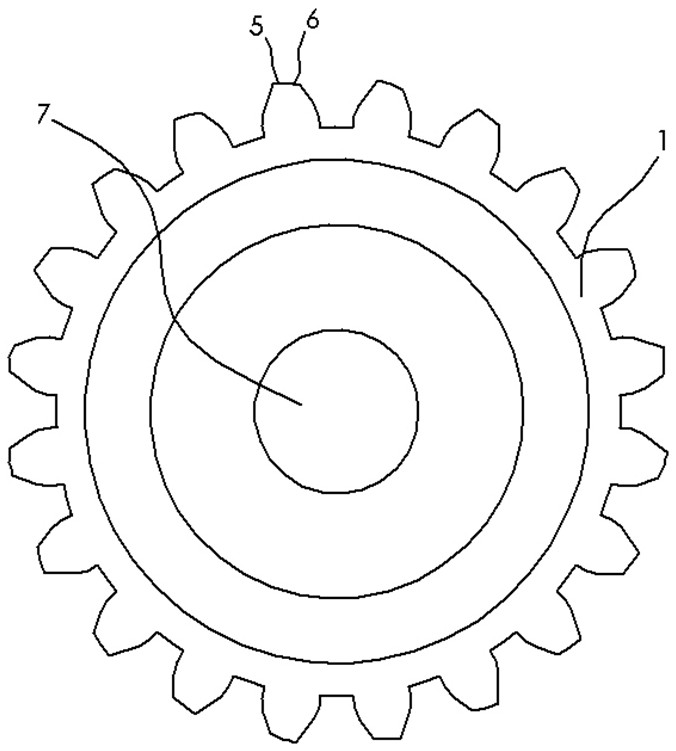

[0027] see figure 1 with figure 2 , according to the design requirements: the shape of the cutter body 1 is the same as that of the pinion in the pair of straight-toothed bevel gears, and the modulus, pressure angle, number of teeth, addendum height coefficient, and head clearance coefficient are all consistent with the pinion; each There are 7 cutter teeth evenly distributed on the straight teeth of the bar, and a tooth groove 3 is opened between two adjacent cutter teeth 2 along the cutter tooth width B direction; the tooth top of each cutter tooth 2 is provided wit...

Embodiment 2

[0031] The gear ratio of a pair of bevel gears is 20:17, the big end modulus is 1mm, the pressure angle is 20 degrees, the tooth width is 4mm, the addendum height coefficient is 1, and the head clearance coefficient is 0.2. This embodiment provides a cutting tool for processing pinion gears, which is used for semi-finishing the soft tooth surface of straight bevel gears, smoothing the workpiece and removing burrs.

[0032] According to the design requirements: the shape of the cutter body 1 is the same as that of the large gear in the pair of straight-toothed bevel gears, and the modulus, pressure angle, number of teeth, addendum height coefficient, and head clearance coefficient are all consistent with the pinion gear; each There are 4 cutter teeth evenly distributed on the straight teeth, and a tooth groove 3 is opened between two adjacent cutter teeth 2 along the cutter tooth width B direction; the tooth top of each cutter tooth 2 is provided with a top edge 5 and a side edg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com