Production method of low-cost low-temperature high-strength container steel 07MnNiVDR

A production method and technology for container steel are applied in the production field of low-cost, low-temperature, high-strength container steel 07MnNiVDR, which can solve the problems of increasing the cost of heat treatment of steel plates and unfavorable market competition, and achieve the effect of avoiding mixed crystal phenomenon and ensuring mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

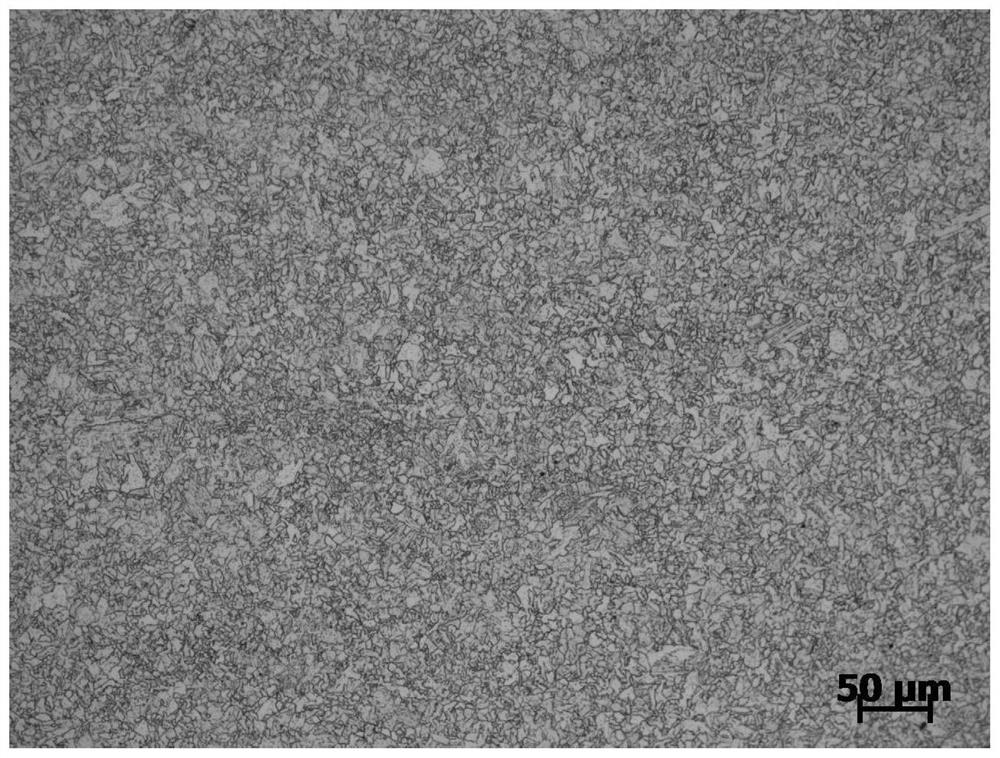

Embodiment 1

[0025] (1) Composition design: In the technical plan, the steel plate 07MnNiVDR with a thickness of less than 60mm and a high-strength tempered pressure vessel contains the following mass percentages (unit, wt%): C: 0.07%, Si: 0.20%, Mn: 1.42%, P: 0.012%, S: 0.003%, Als: 0.020%, Ni: 0.35%, Cr: 0.22%, Mo: 0.15%, V: 0.025, others are Fe and residual elements, crack sensitivity coefficient Pcm = 0.18.

[0026] (2) Heating process: use 210mm cross-section steel billet to produce 15mm thick finished steel plate, the temperature of preheating section is controlled at 1050°C, the temperature of secondary heating is controlled at 1250°C, the temperature of soaking section is controlled at 1230°C, and the heating time is 210min.

[0027] (3) Controlled rolling and controlled cooling: the starting rolling temperature is 1100°C. In order to realize the refinement of the core grain structure of the billet, the single-pass reduction in the rough rolling link is 30mm, the thickness of the i...

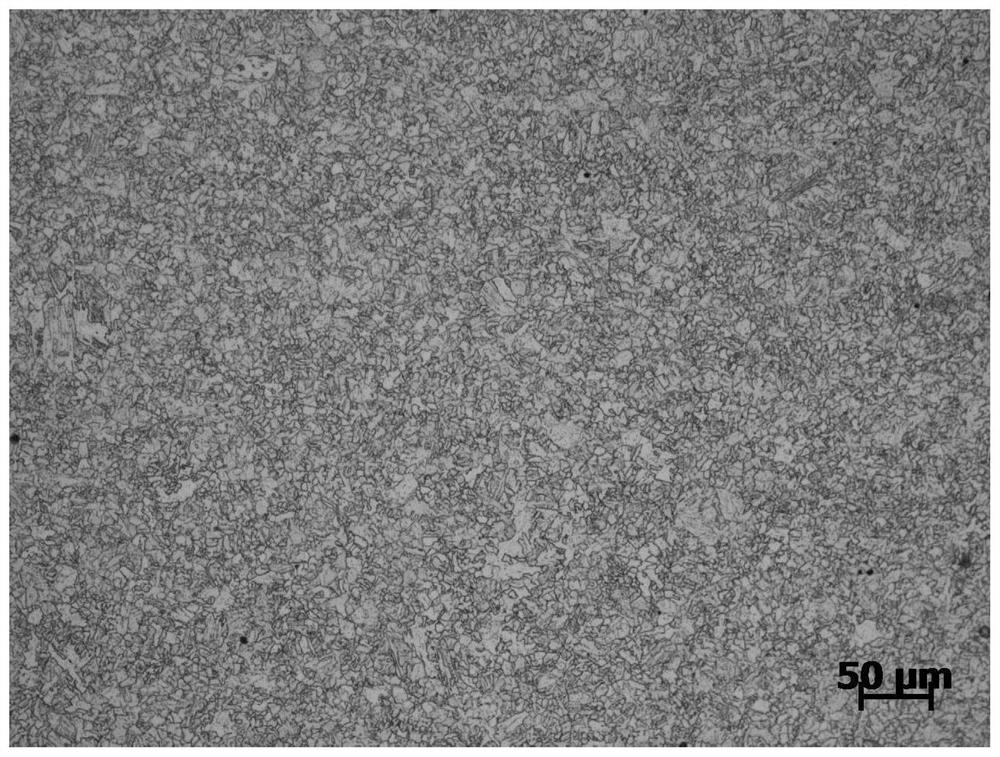

Embodiment 2

[0031] (1) Composition design: In the technical plan, the steel plate 07MnNiVDR with a thickness of less than 60mm and a high-strength tempered pressure vessel contains the following mass percentages (unit, wt%): C: 0.08%, Si: 0.25%, Mn: 1.45%, P: 0.012%, S: 0.003%, Als: 0.022%, Ni: 0.36%, Cr: 0.23%, Mo: 0.17%, V: 0.030, others are Fe and residual elements, crack sensitivity coefficient Pcm = 0.19.

[0032] (2) Heating process: 300mm cross-section steel billet is used to produce 60mm thick finished steel plate, the temperature of the preheating section is controlled at 1040°C, the temperature of the second heating section is controlled at 1260°C, the temperature of the soaking section is controlled at 1250°C, and the heating time is 300min.

[0033] (3) Controlled rolling and controlled cooling: the starting rolling temperature is 1108°C. In order to realize the refinement of the core grain structure of the billet, the single-pass reduction in the rough rolling link is 25mm, t...

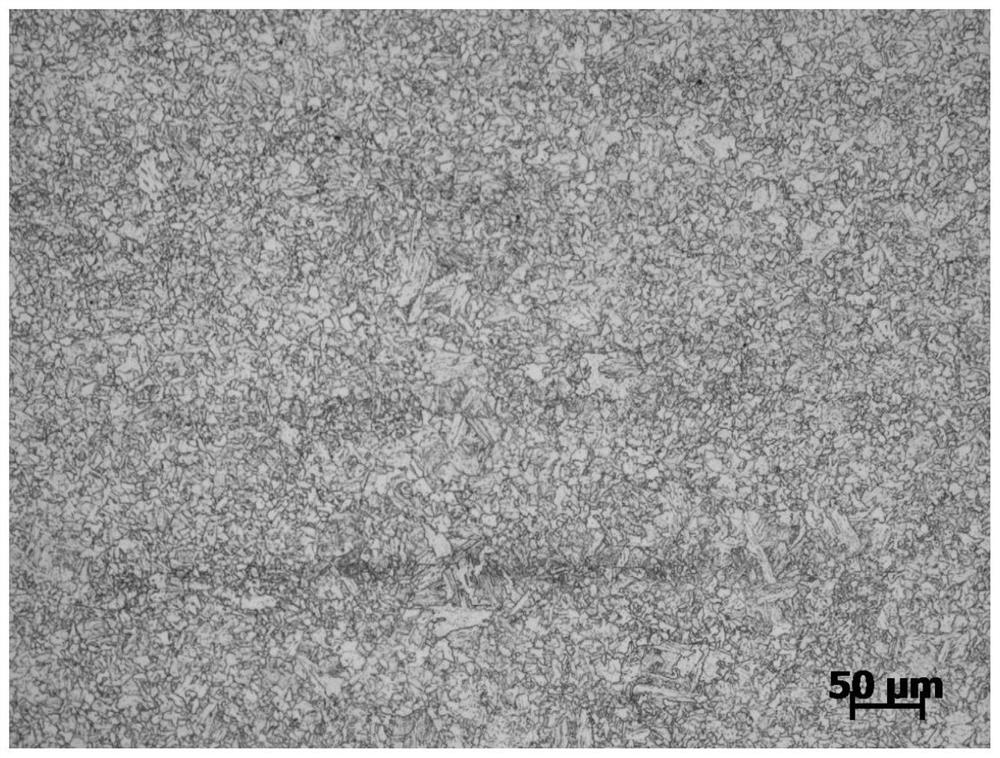

Embodiment 3

[0037] (1) Composition design: In the technical plan, the steel plate 07MnNiVDR with a thickness of less than 60mm and a high-strength tempered pressure vessel contains the following mass percentages (unit, wt%): C: 0.08%, Si: 0.25%, Mn: 1.41%, P: 0.011%, S: 0.003%, Als: 0.025%, Ni: 0.32%, Cr: 0.26%, Mo: 0.15%, V: 0.029, others are Fe and residual elements, crack sensitivity coefficient Pcm = 0.19.

[0038] (2) Heating process: use 300mm cross-section steel billet to produce 38mm thick finished steel plate, the temperature of preheating section is controlled at 1038°C, the temperature of secondary heating is controlled at 1255°C, the temperature of soaking section is controlled at 1247°C, and the heating time is 300min.

[0039](3) Controlled rolling and controlled cooling: the starting rolling temperature is 1110°C. In order to realize the refinement of the core grain structure of the steel billet, the single-pass reduction in the rough rolling link is 27mm, the thickness of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com