Soil retaining assembly and connecting embedded steel bar anchoring method thereof

An anchoring method and bar-planting technology, applied in construction, artificial island, infrastructure engineering, etc., to achieve the effect of convenient implementation and clear process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

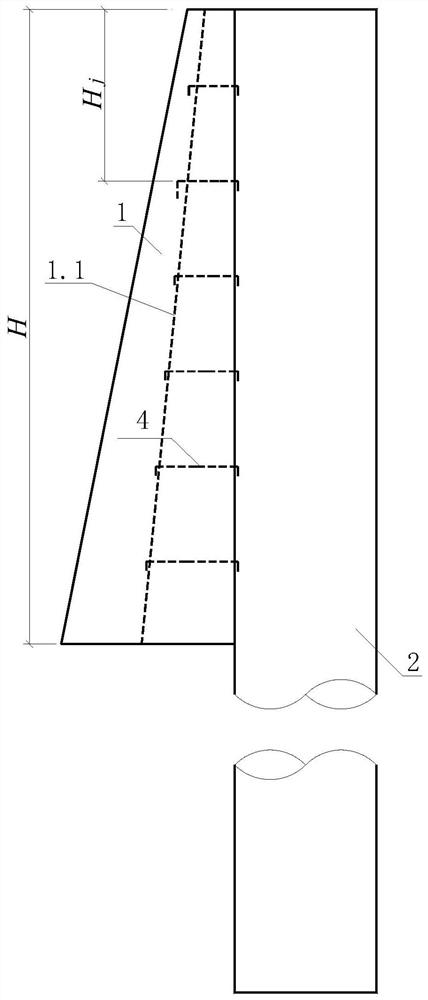

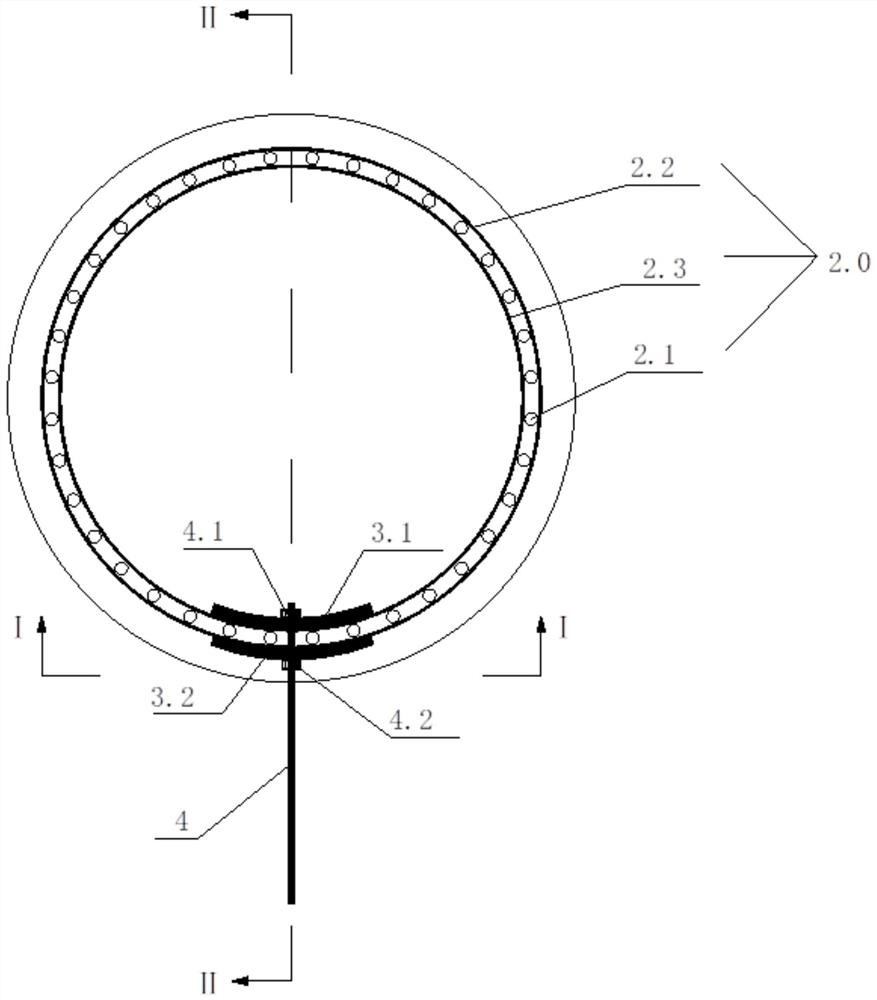

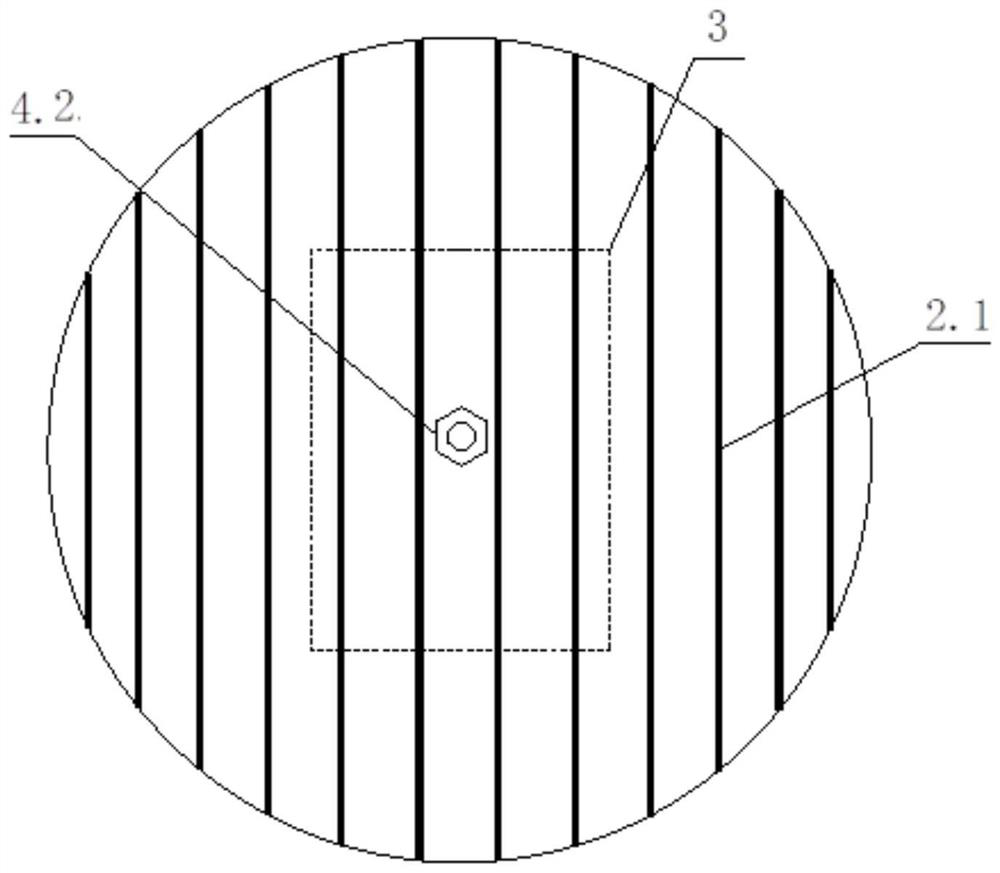

[0059] Such as Figure 1-4 As shown, a retaining assembly described in this embodiment includes a retaining wall 1, a reinforcing mesh 1.1 is embedded in the retaining wall 1, and a bored pile 2 is arranged on one side of the retaining wall 1, so that The bored pile 2 is vertically provided with an annular reinforcement cage 2.0, the inner side of the annular reinforcement cage 2.0 is provided with an inner arc-shaped steel plate 3.1, and the outer side of the annular reinforcement cage 2.0 is provided with an outer arc-shaped steel plate 3.2. The earth wall 1 is connected with a connection planting bar 4, specifically, the connection planting bar 4 is connected with the steel mesh 1.1, and the connection planting bar 4 runs through the inner arc-shaped steel plate 3.1 and the outer arc-shaped steel plate 3.2. The side of the inner curved steel plate 3.1 facing away from the annular reinforcement cage 2.0 abuts against a first lock nut 4.1, and the side of the outer curved ste...

Embodiment 2

[0069] A method for connecting and planting reinforcement anchorage in a soil retaining assembly described in the present application, wherein there are at least two bored piles 2, and all the bored piles 2 are longitudinally spaced apart along the retaining wall 1, Contains the following steps:

[0070] S1. Determine the soil internal friction angle between two adjacent bored piles and the soil weight γ between adjacent bored piles 2, the spacing l between adjacent bored piles 2, the size parameters of bored piles 2 and the size parameters of retaining wall 1 are drawn up;

[0071] S2. Obtain the horizontal cross-sectional area A of the soil and non-soil arch area 5 between the adjacent bored piles 2 based on the distance l between the adjacent bored piles 2 and the size parameters of the bored piles 2, wherein there is a gap between the adjacent bored piles 2 Soil arch ring 6, the soil inside the soil arch ring 6 is the soil and non-soil arch area 5 between the bored piles...

Embodiment 3

[0130] In this embodiment, a specific test is used to further illustrate an anchoring method for connecting planting bars in soil retaining components:

[0131] A certain section of railway is located in high mountains and deep valleys, and the weather is extremely harsh. The terrain is generally flat, with a surface elevation of 2930-2960m and a relative height difference of about 30m. The surface is mostly barren land and a small amount of vegetation is covered. The covering layer of this section is mainly the alluvial fine sand and pebble soil of the Quaternary Holocene system, the groundwater level is 12m below the surface, and the peak acceleration of ground motion in the section is 0.3g. Section DK395+570.5~DK395+620, on the left side of the line, set up cutting bored piles 2 and reinforcement retaining wall 1, and the height of retaining wall 1 is H=7.0m. The distance between the two bored piles is l=2.0m, the diameter d=1.5m, the pile length is 9.0m~20.0m, and the pile ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com