Emergency brake prevention type hydraulic disc brake

A disc brake, emergency brake technology, applied in the direction of brakes, brake types, bicycle brakes, etc., can solve the problems of potential safety hazards, the inability to install anti-lock braking systems, etc., and achieve the effect of reducing the flow rate and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

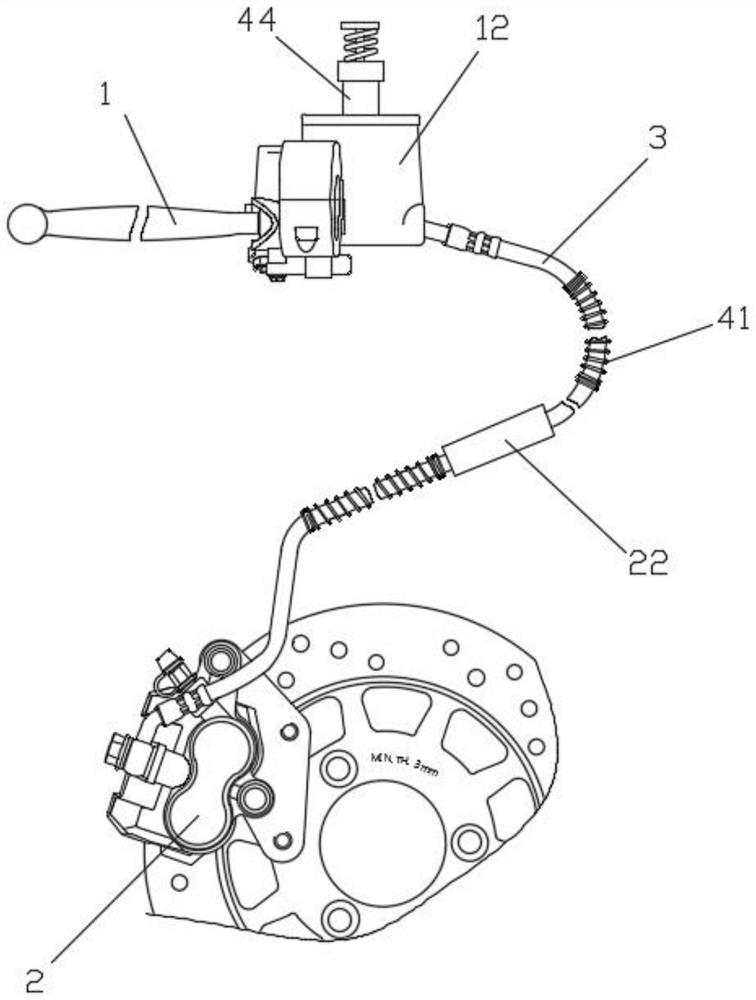

[0026] Such as Figure 1-2 As shown, an anti-sudden brake type hydraulic disc brake includes:

[0027] Handbrake 1, brake unit 2, linkage tubing 3;

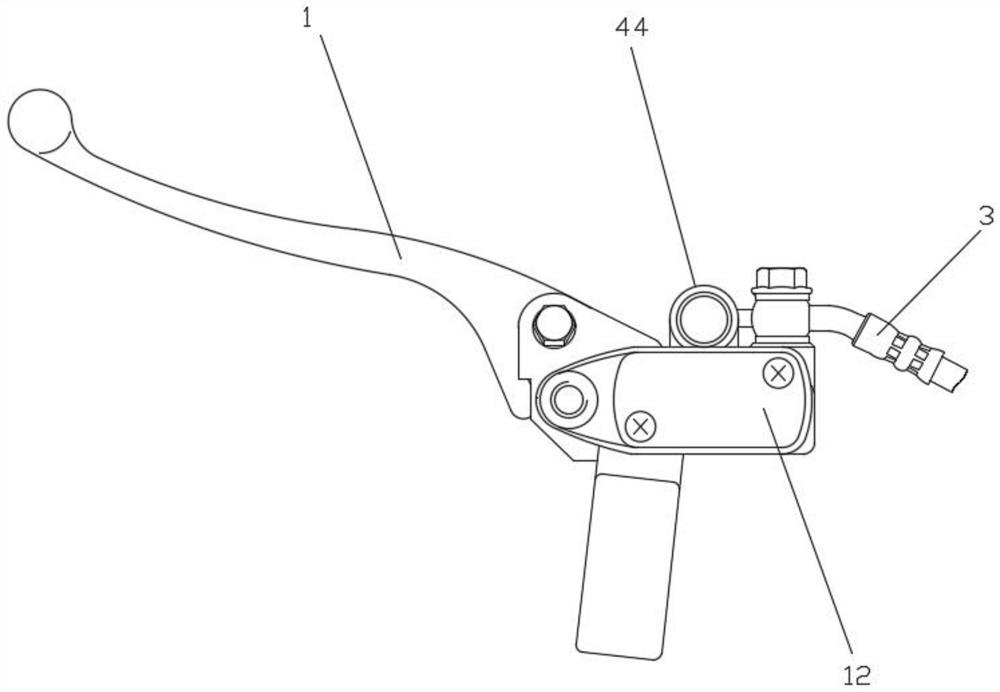

[0028] The handbrake 1 is provided with a drive cylinder 12, and the drive cylinder 12 is connected to the brake unit 2 through a linkage oil pipe 3; the linkage oil pipe 3 includes a pipe body 21 and a buffer node 22;

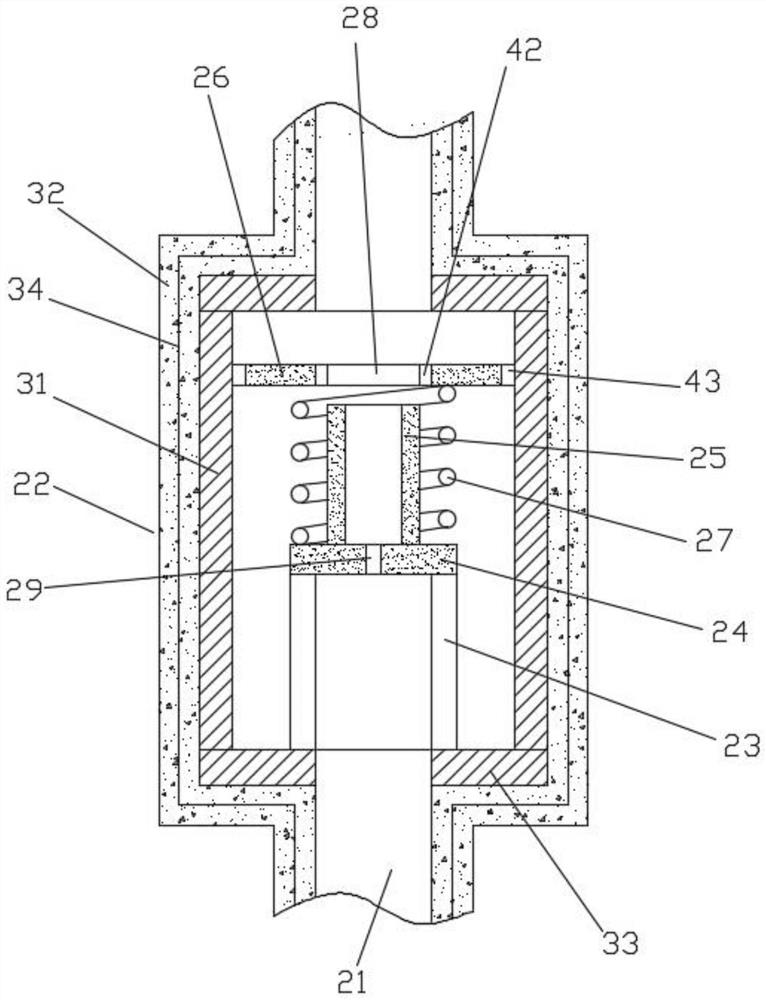

[0029] The buffer node 22 is connected to the pipe body 21, and the inside of the buffer node 22 is provided with a cavity, and a support guide post 23 is installed at the bottom of the cavity, a support plate 24 is fixed on the support guide post 23, and a sleeve 25 is fixed on the support plate 24, A floating plate 26 is slidably installed inside the cavity. A buffer spring 27 is provided between the floating plate 26 and the support plate 24. A perforation 28 is provided in the middle of the floating plate 26. When the floating plate 26 moves in the cavity, the sleeve 25 can be inserted into the perforation. ...

Embodiment 2

[0033] On the basis of Example 1, such as Figure 1-5 As shown, the buffer node 22 includes a cylinder liner 31 and an outer rubber layer 32, the two ends of the cylinder liner 31 are respectively equipped with connecting end caps 33, the support guide post 23 is fixed on one of the connecting end caps 33, and the outer rubber layer 32 is looped on the Outside the cylinder liner 31, a steel wire mesh 34 is embedded in the outer rubber layer 32.

[0034] A protective spring 41 is sheathed on the outside of the pipe body 21 .

[0035] An inner sealing rubber ring 42 is embedded inside the perforation 28 , and the inner sealing rubber ring 42 and the sleeve 25 are interference fit.

[0036] The outer ring of the floating plate 26 is surrounded by an outer sealing rubber ring 43 , and the outer sealing rubber ring 43 and the cylinder liner 31 are in an interference fit.

[0037] A display oil column 44 is installed on the handbrake 1, and the inside of the display oil column 44 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com