Portable engineering quality detection equipment based on network

A technology of engineering quality and testing equipment, which is applied in the direction of measuring devices, testing material hardness, instruments, etc., can solve the problems of unfavorable environmental protection scribing devices, a large amount of debris and dust, cumbersome operation, etc., and increase the convenience of installation , Enhanced mobile efficiency and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

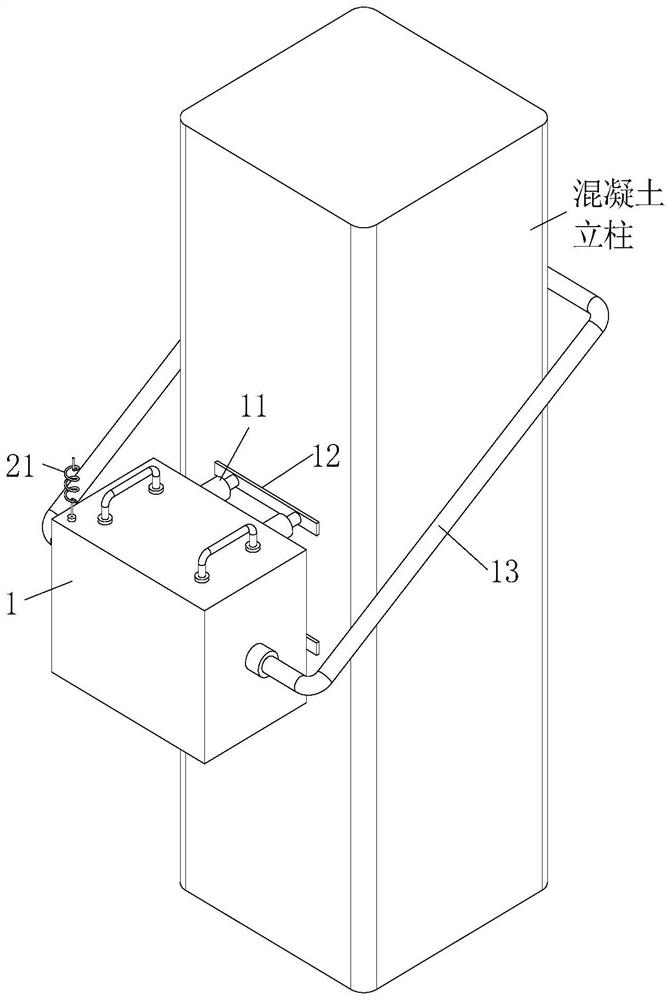

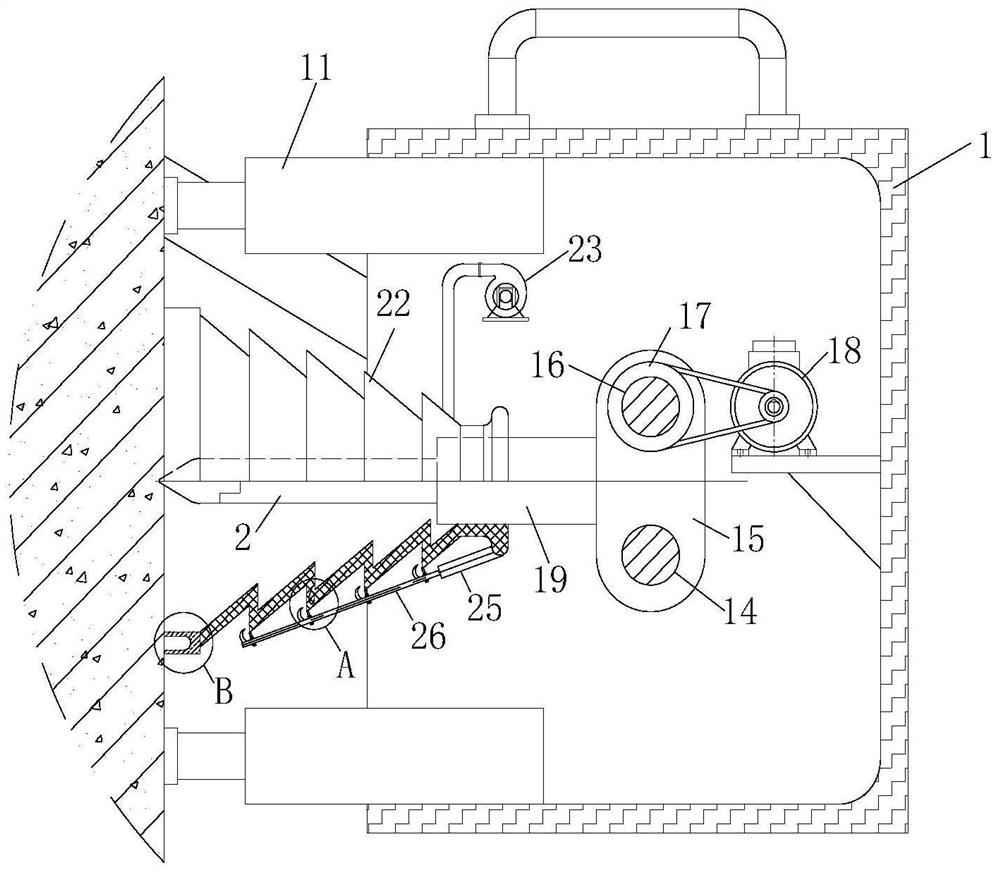

[0030] Such as Figure 1 to Figure 2 As shown, a network-based portable engineering quality inspection device described in the embodiment of the present invention includes a body 1; a set of push cylinders 11 are arranged on one side of the body 1, and a top plate 12 is fixedly connected to the movable end of the push cylinders 11. The two sides of the body 1 are rotated and connected with C-shaped holding bars 13, the body 1 is fixedly connected with the slide bar 14, the slide bar 14 is covered with a slide table 15, and the slide table 15 is slidably connected with the slide bar 14; The side of table 15 away from slide rod 14 runs through a screw rod 16, which is rotationally connected with body 1, and the screw rod 16 is connected with slide table 15 through a screw nut pair, and the screw rod 16 is fixedly connected with a pulley 17 near the end, and the body 1 The position corresponding to the pulley 17 is fixedly connected with a motor 18 through a bracket, and the outp...

Embodiment 2

[0041] Such as Figure 5 Shown, comparative example one, wherein another kind of implementation mode of the present invention is:

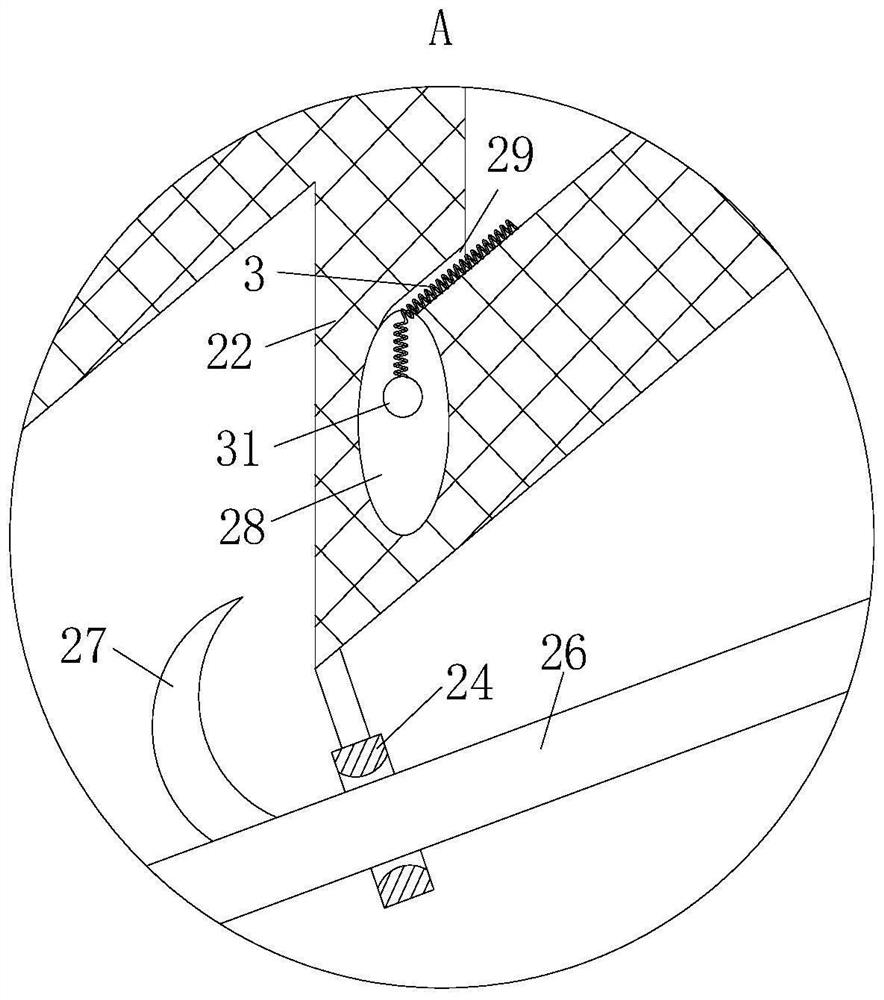

[0042] A group of exhaust holes 44 are evenly distributed on the inner circumference of the magnetic sheet 42, and one end of the exhaust holes 44 near the outer circumference of the nozzle pipe 41 is inclined toward the end of the nozzle pipe 41; The edge is hinged with a baffle 45, the baffle 45 has magnetism, and the baffle 45 and the magnetic sheet 42 repel each other, the baffle 45 and the magnetic block 43 near the bottom are mutually attracted; The direction of the end of the nozzle 41 is inclined to increase the transport efficiency of the residual dust and debris near the end of the nozzle 41, and the airflow at the end of the nozzle 41 passes through the residual dust in the inner periphery of the nozzle 41 to further move closer. The inner center position of the dust cover 22 is transported, and when the elastic ring 32 inside the annu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com