Preparation method and application of conductive electrode and composite cover plate glass

A cover glass and conductive electrode technology, which is applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve problems such as increasing costs and increasing process flow, and achieve the effects of prolonging service life, simplifying the preparation process, and highly efficient waterproofing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The present invention also provides a method for preparing the above-mentioned composite cover glass, comprising the following steps:

[0052] A) Design a mask with lotus leaf vein texture structure;

[0053] B) Composite waterproof base material layer on the outside of the cover glass, then cover the mask plate on the surface of the waterproof base material layer, then compound the lotus leaf vein texture layer, remove the mask plate, and obtain the composite cover plate glass .

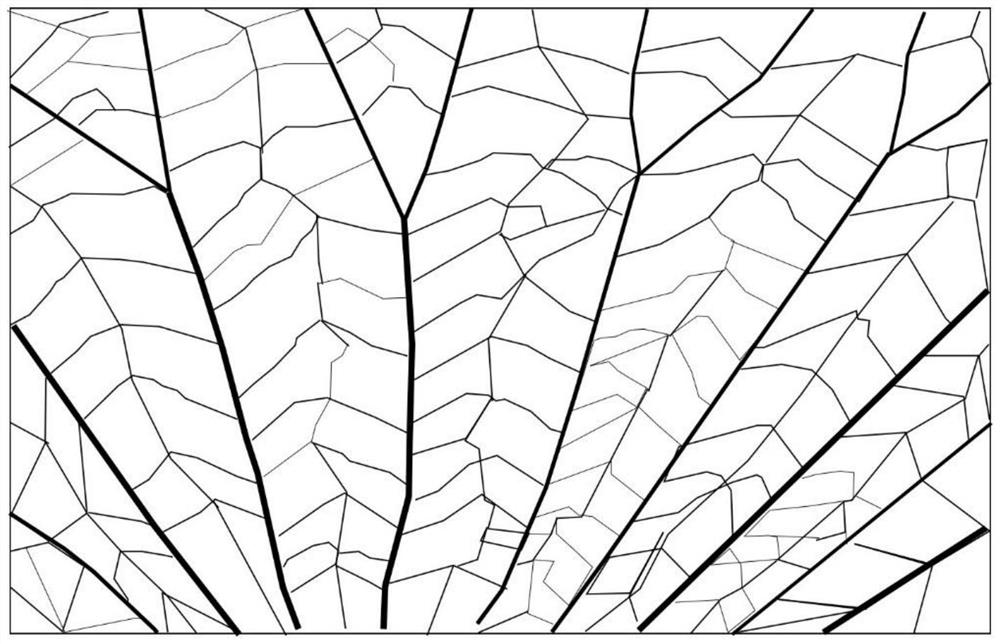

[0054] The present invention firstly designs a mask plate with a lotus leaf vein texture structure. see image 3 , image 3 It is a schematic diagram of a mask with lotus leaf vein texture structure. In the figure, the vein texture structure of the lotus leaf with black stripes is a hollow structure, and the leaf position is a solid structure, or the vein texture structure of the lotus leaf with black stripes is a solid structure, and the leaf position is a hollow structure.

[0055] (1)...

Embodiment 1

[0128] This embodiment provides a perovskite battery prepared based on the transparent conductive electrode and cover glass of the present invention, and the specific preparation method is as follows:

[0129] S1) MgF was deposited by vacuum evaporation 2 Deposit on the back side of cover glass (6), obtain the waterproof substrate layer that thickness is 10nm, then image 3 After the mask plate shown is covered on the surface of the waterproof substrate layer, the lotus leaf vein-like texture layer is vacuum-evaporated to form a bionic nano-grid texture with a raised structure; the raised structure has a width of 1 nm and a height of 0.05nm.

[0130] Wherein, the specific preparation parameters of the vacuum evaporation are as follows: the evaporation power is 254W; the evaporation rate is: 0.1 Angstroms / second. The background vacuum is -4 Pa. Target base distance: 40cm.

[0131]S2) Place Au / ITO on the inner side of the cover glass (6) sequentially by vacuum evaporation me...

Embodiment 2

[0142] This embodiment provides a perovskite battery prepared based on the transparent conductive electrode and cover glass of the present invention, and the specific preparation method is as follows:

[0143] S1) MgF was deposited by vacuum evaporation 2 Deposit on the back side of cover glass (6), obtain the waterproof substrate layer that thickness is 10nm, then image 3 After the mask plate shown is covered on the surface of the waterproof substrate layer, the lotus leaf vein-like texture layer is vacuum-evaporated to form a bionic nano-grid texture with a raised structure; the width of the raised structure is 0.1nm, and the height 0.05nm.

[0144] Wherein, the specific preparation parameters of the vacuum evaporation are as follows: the evaporation power is 254W; the evaporation rate is: 0.3 Angstroms / second. The background vacuum is -4 Pa. Target base distance: 40cm.

[0145] S2) Place Au / ITO on the inner side of the cover glass (6) sequentially by vacuum evaporation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com