Bleaching wastewater treatment system

A wastewater treatment system and body technology, applied in separation methods, filtration separation, chemical instruments and methods, etc., can solve problems affecting filtration efficiency, reducing performance, and accumulation of impurities, so as to avoid accumulation of impurities, prevent clogging, reduce The effect of limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

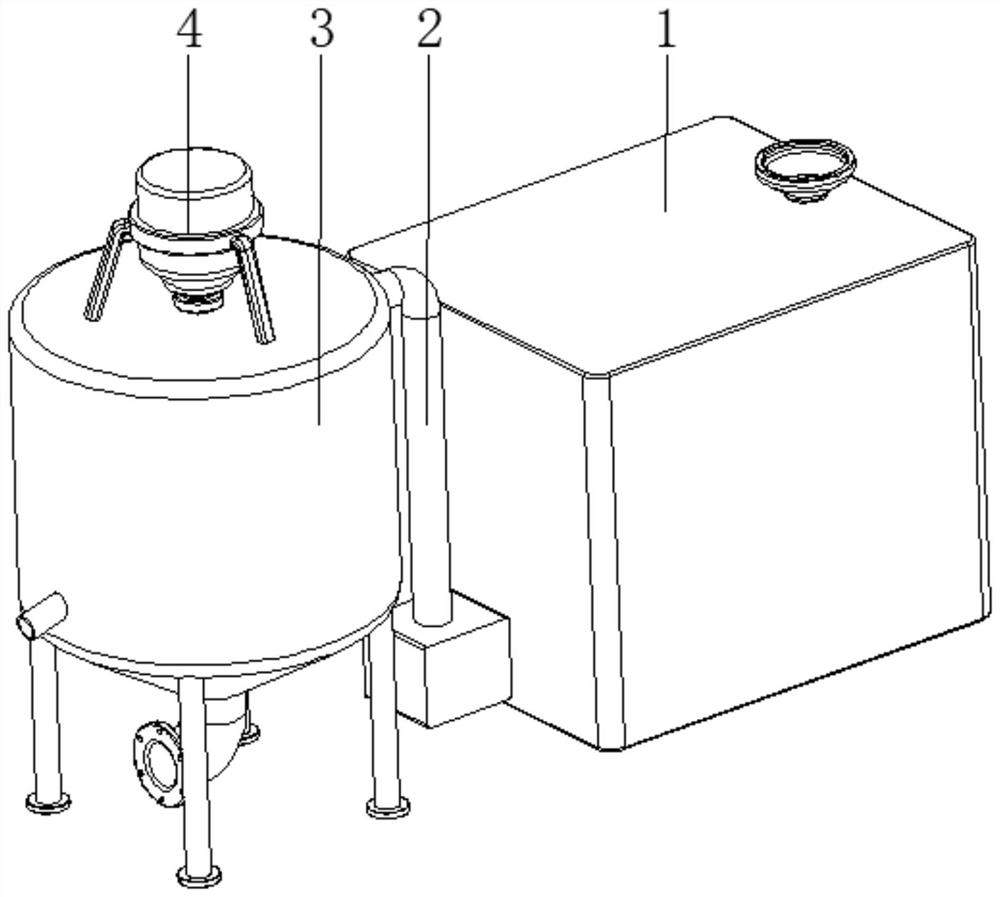

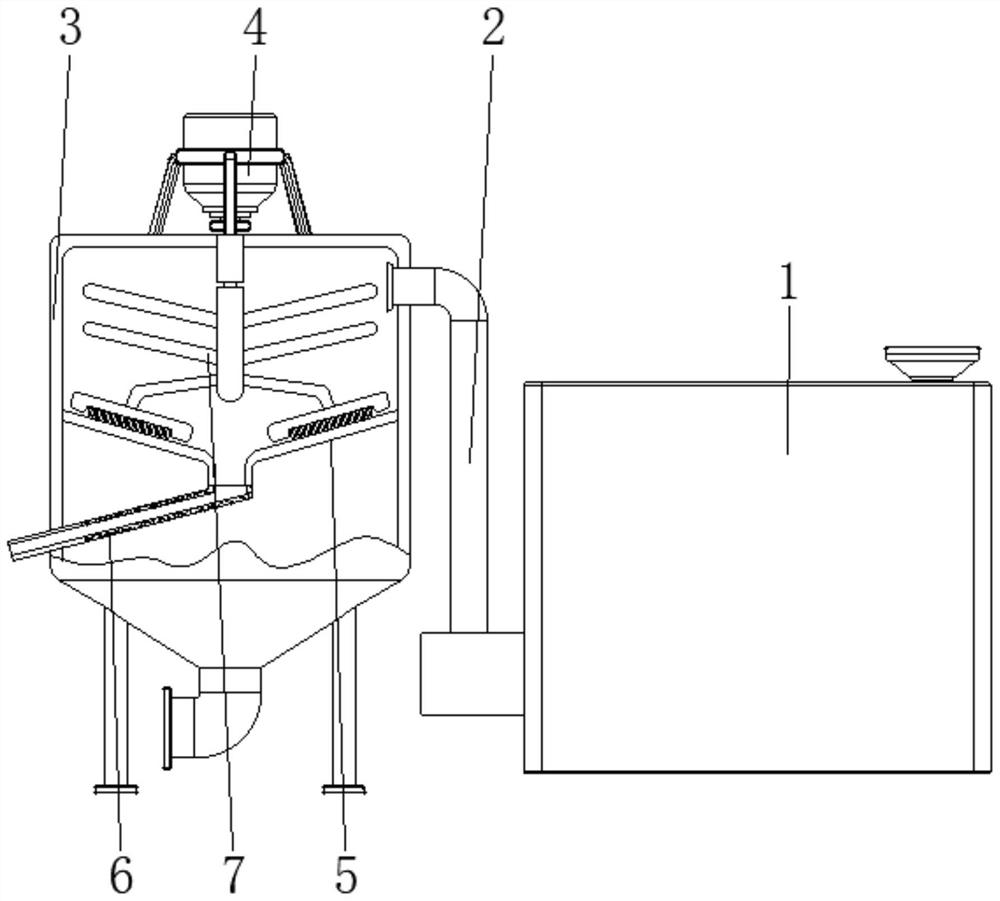

[0029] see Figure 1-6 , the present invention provides a technical solution: a bleaching wastewater treatment system, comprising a sedimentation tank 1, a conveying mechanism 2, a body 3, and a power mechanism 4, one end of the conveying mechanism 2 is arranged on the bottom side of the surface of the sedimentation tank 1, and the body 3 Set at the end of the conveying mechanism 2 away from the sedimentation tank 1, the conveying mechanism 2 communicates between the sedimentation tank 1 and the body 3, and the power mechanism 4 is set at the top center of the body 3;

[0030] The interior of the body 1 is provided with a filter device 5, an impurity guide tube 6, and a toggle device 7. The filter device 5 is arranged inside the body 3 and is located at a central position, and the impurity guide tube 6 is arranged at the bottom center of the filter device 5. One end of the impurity diversion pipe 6 runs through the inner wall of the body 3 and extends to the outside, the toggl...

Embodiment example 2

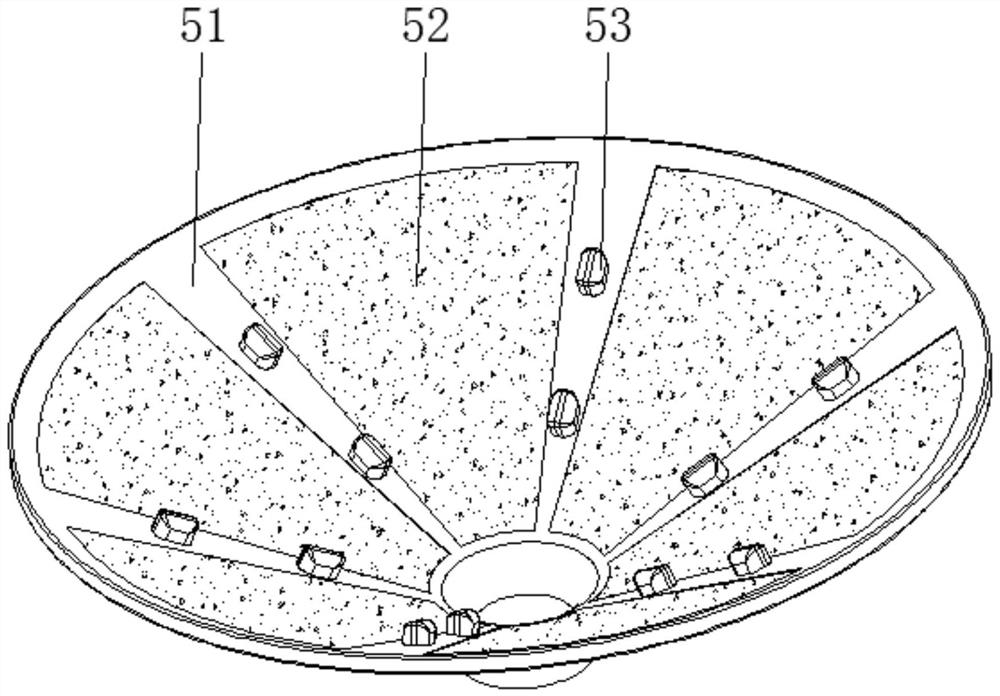

[0032] Filtration device 5 is provided with conical frame 51, fan-shaped filter screen 52, projection 53, and the surface edge of conical frame 51 is fixedly connected with the inner wall of body 3, and fan-shaped filter screen 52 is fixed on the inner wall of conical frame 51, protruding The block 53 is fixed on the inner wall of the conical frame 51 and close to the fan-shaped filter screen 52. After the bleaching wastewater is transported into the body 3 through the conveying mechanism 2, it is filtered through the fan-shaped filter screen 52, and the filter residue automatically slides down through the conical surface. And it is discharged by the impurity guide pipe 6, and with the continuous rotation of the elastic knocking device 734, and under the action of the protrusion 53, the fan-shaped filter screen 52 is elastically knocked, and then the fan-shaped filter screen 52 will be attached to the surface of the fan-shaped filter screen 52. The impurities are shot down to a...

Embodiment example 3

[0034] Actuating device 7 is provided with rotating roller 71, stirring blade 72, scrubbing device 73, and the surface top of rotating roller 71 is connected with rotation between body 3, and the top of rotating roller 71 runs through the inner wall top of body 3 and extends to its outside and Cooperate and connect with the power mechanism 4, the stirring blade 72 is fixed on the surface of the rotating roller 71, and the brushing device 73 is arranged on the surface bottom of the rotating roller 71, and the rotating roller 71 is driven by the driving mechanism 4, and the stirring blade 72, The scrubbing device 73 will also rotate rapidly thereupon, and the stirring blade 72 will evenly sprinkle the bleaching waste water on the filter device 5, so as to avoid accumulation of impurities. The impurities that come down are cleaned up, and then the effect of automatic slag discharge is realized, so as to avoid the accumulation of impurities and prevent clogging, which is helpful fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com