Preparation process of high-strength porcelain insulator for power transmission

A porcelain insulator and a preparation process technology, which is applied in the preparation process of high-strength power transmission porcelain insulators and the field of porcelain insulators, can solve the problems of low mechanical strength and achieve the effects of improving texture uniformity, improving quality, and improving load-bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

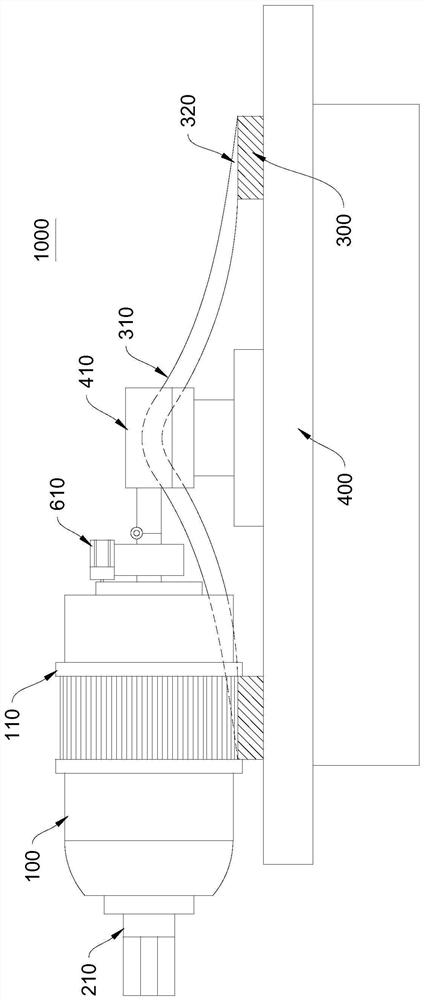

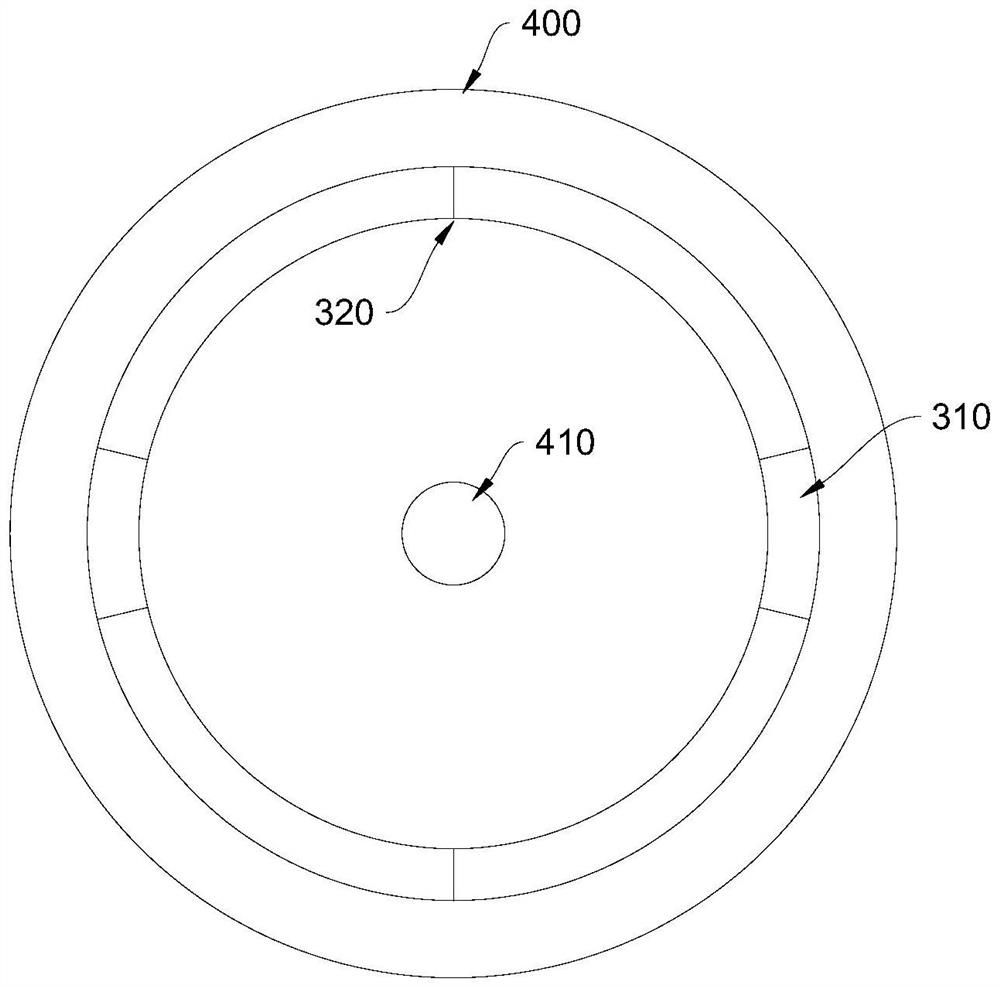

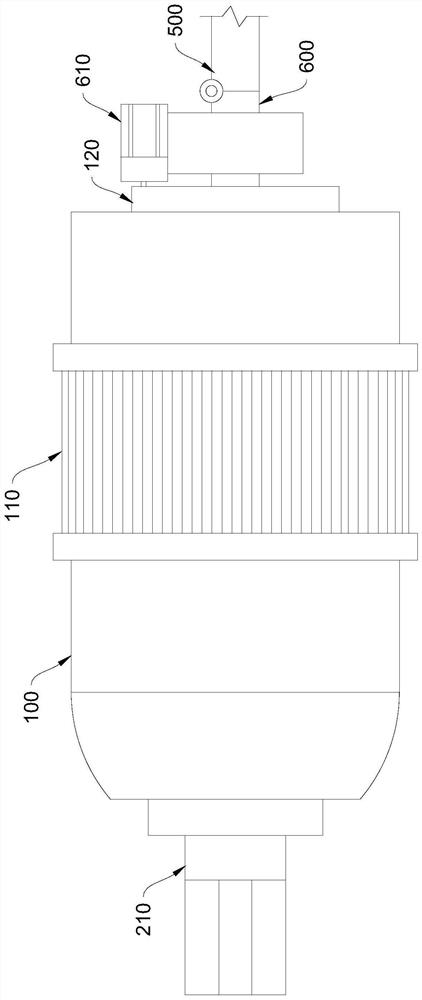

[0064] This embodiment provides a preparation process of a high-strength porcelain insulator for power transmission. The preparation process of a high-strength power transmission porcelain insulator includes the following steps:

[0065] S1. Mix the raw materials of the blank layer evenly;

[0066] S2, adding deionized water with 50% raw material quality of the embryo material layer, and ultrasonic treatment for 5-8min to obtain the embryo material layer slurry;

[0067] S3. Squeeze the mud after removing iron from the embryo material layer slurry, extrude the obtained mud cake in a vacuum mud refining machine, and then perform electric shade drying on the obtained mud section, and obtain a green body after drying;

[0068] S4. Mix the raw materials of the enamel layer evenly, add deionized water with a mass of 30% of the raw material of the enamel layer, and stir evenly to obtain the enamel layer slurry;

[0069] S5. Carry out glazing, firing, and glue-fitting of the enamel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com