High-salt sewage pretreatment system

A high-salt sewage and pretreatment technology, applied in the direction of oxidized water/sewage treatment, water/sludge/sewage treatment, water pollutants, etc., can solve the problem of single functional modules, poor anti-fouling performance, narrow flow channel space, etc. problem, to achieve the effect of wide channel space, fast and convenient process, and slow down electrode pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

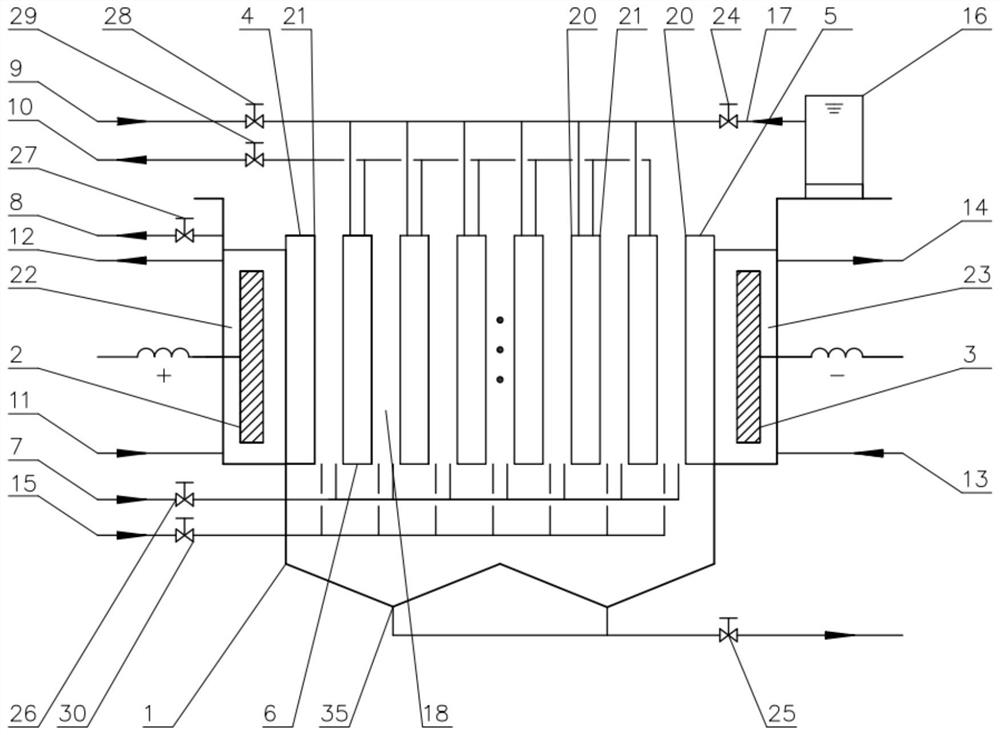

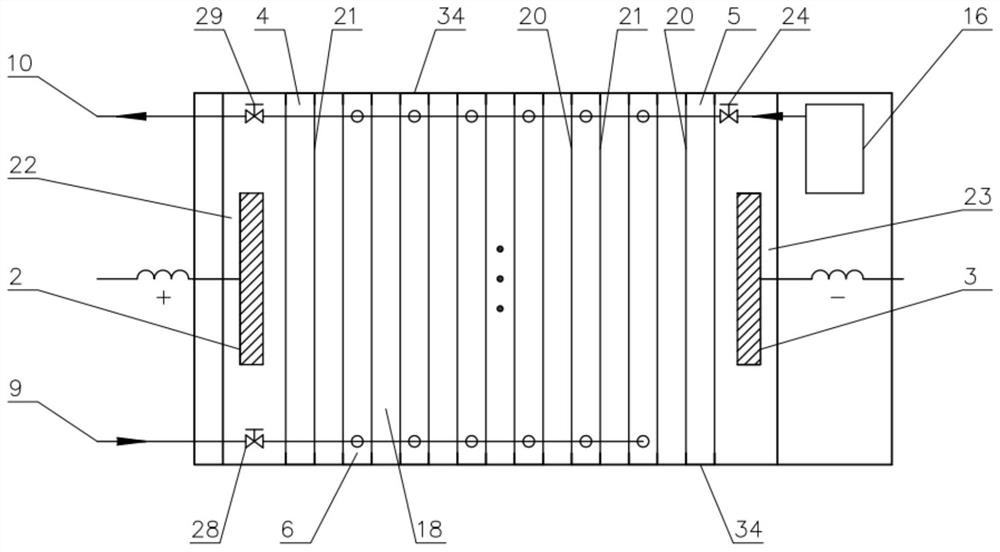

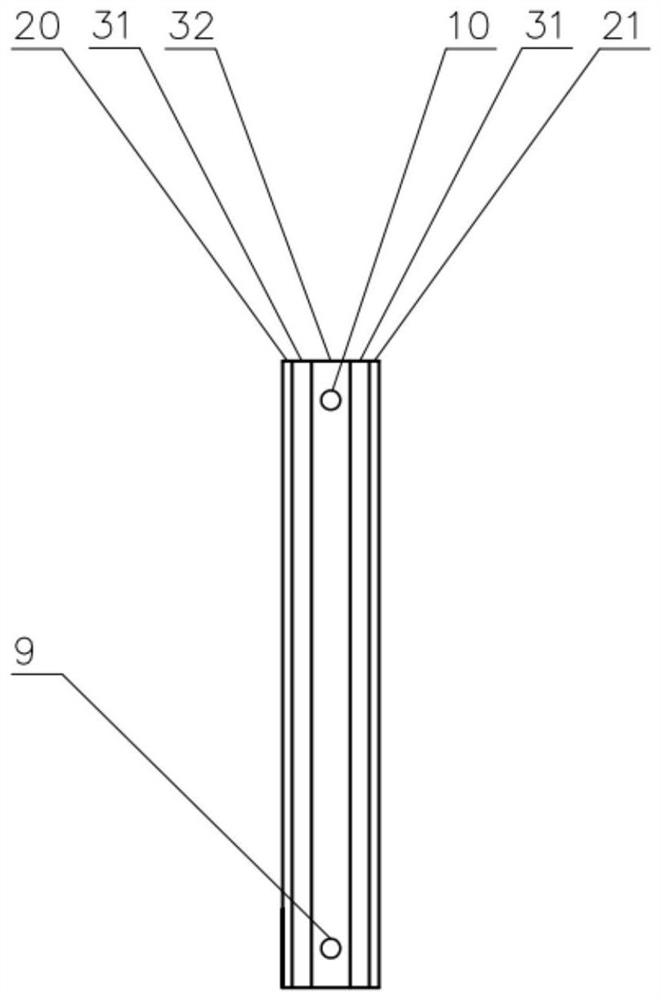

[0024] Such as figure 1 The shown high-salt sewage pretreatment system includes a composite pool 1, a plurality of u-shaped slots 34 are respectively connected to the front and rear inner walls of the composite pool 1, and the front and rear sides of a plurality of concentration chamber elements 6 are respectively Insert in the u-shaped slot 34 of composite pool 1 inner wall.

[0025] An anode chamber 22 and a cathode chamber 23 are respectively fixed on the left inner wall and the right inner wall of the composite pool 1, and an anode 2 connected to the positive pole of the power supply is arranged in the anode chamber 22. The anode chamber 22 is respectively connected to the water outlet end of the anode water inlet pipe 11 and the water inlet end of the anode water outlet pipe 12, and a cathode electrode 3 connected to the negative pole o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com