Treatment method for salt-containing wastewater

A technology of salty wastewater and treatment methods, applied in the directions of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of increasing sewage treatment costs, secondary pollution, and low desulfurization efficiency, etc. problems, to achieve the effect of improving industrial water utilization, saving treatment costs, and good treatment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

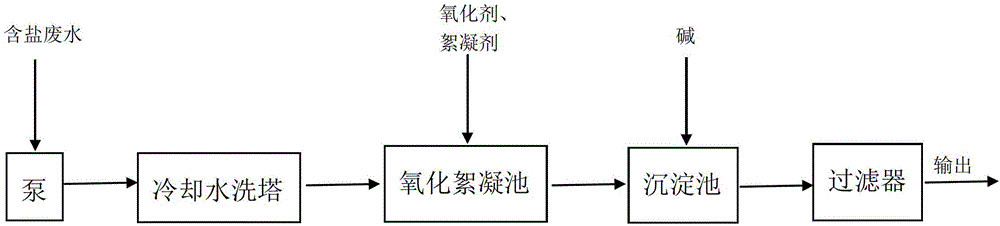

[0047] 1.4 million tons / year catalytic cracking unit in an oil refinery, with a flue gas volume of 150,000 NM 3 / h, temperature 200℃, adopt wet flue gas desulfurization technology, 20t / h reverse osmosis concentrated water enters cooling water washing tower, adopts figure 1 The process flow shown, its operating conditions are as follows:

[0048] After the reverse osmosis concentrated water reacts in the cooling water washing tower for 2 minutes, it enters the oxidation flocculation tank for aeration and oxidation. The volume ratio of air to water is 3:1, the addition amount of flocculant polyaluminum chloride is 9 mg / L, and the residence time is 20 minutes. .

[0049] The reverse osmosis concentrated water enters the neutralization and sedimentation tank from the oxidation flocculation tank, and sodium hydroxide is added to adjust the pH to 7.5, and the residence time is 30 minutes. After precipitation, the inclined plate enters into a multi-media filter with coal and quartz s...

Embodiment 2

[0054] 1.4 million tons / year catalytic cracking unit in an oil refinery, with a flue gas volume of 150,000 NM 3 / h, the temperature is 200 °C, the wet flue gas desulfurization technology is used, and the 40 tons / hour reverse osmosis concentrated water, circulating water sewage, reclaimed reverse osmosis concentrated water, electrodialysis concentrated water and other salty wastewater are mixed. Water is used as the process water of the washing tower, using figure 1 The process flow shown, its operating conditions are as follows:

[0055] After the reverse osmosis concentrated water reacts in the cooling water washing tower for 5 minutes, it enters the oxidation flocculation tank, and the oxidant ozone is added at 40 mg / L, the flocculant polymerized iron sulfate is added at 9 mg / L, and the residence time is 10 minutes.

[0056] The wastewater enters the neutralization and sedimentation tank from the oxidation flocculation tank, and potassium hydroxide is added to adjust the pH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com