High-nitrogen type macroelement water-soluble fertilizer powder, production process and preparation device of high-nitrogen type macroelement water-soluble fertilizer powder

A technology of a large number of elements and a preparation device, which is applied in fertilization devices, nitrogen fertilizers, urea compound fertilizers, etc., can solve problems such as affecting product quality and affecting production efficiency, and achieve the effect of reducing production costs and preventing easy agglomeration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The high-nitrogen macronutrient water-soluble fertilizer powder comprises the following components in parts by weight: 22 parts of potassium nitrate, 17 parts of ammonium dihydrogen phosphate, 54 parts of urea, 4 parts of sodium silicate, 2 parts of boric acid, and 1 part of zinc sulfate.

Embodiment 2

[0035] The production process of high-nitrogen type macroelement water-soluble fertilizer powder comprises the following steps:

[0036] Step 1: Potassium nitrate, ammonium dihydrogen phosphate, and urea are weighed and transported to the mixer in proportion at the raw material feeding port to obtain a first-grade mixed product;

[0037] Step 2: Put boric acid, zinc sulfate and sodium silicate solutions in a small amount of water in proportion, and mix them uniformly to obtain a boron-zinc-silicon solution; the small amount of water is the water used to just dissolve boric acid, zinc sulfate and sodium silicate;

[0038] Step 3: Spray the boron-zinc-silicon solution evenly on the primary mixture in step 1 through the Jiaolong internal spraying device, and fully stir it at 40 degrees to obtain a high-nitrogen type macronutrient water-soluble fertilizer powder.

Embodiment 3

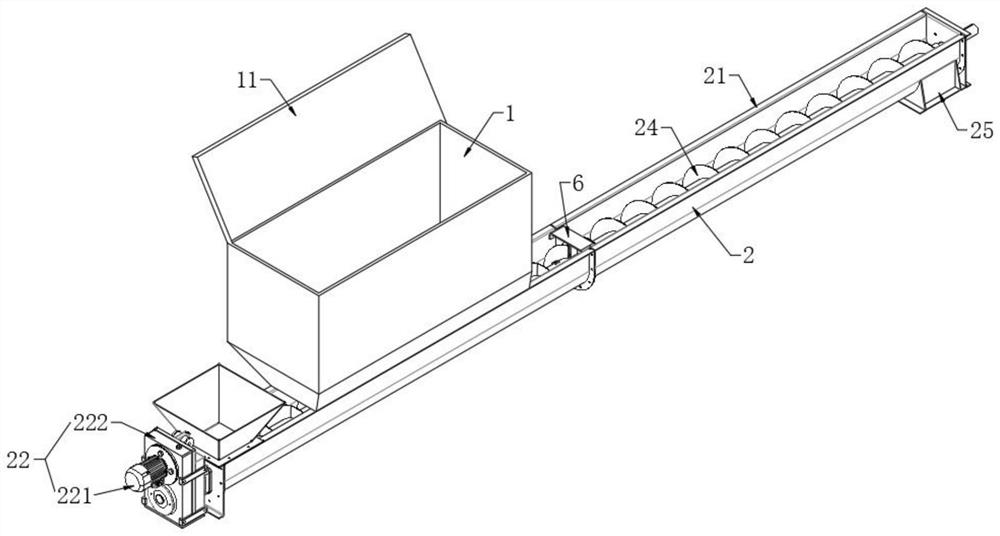

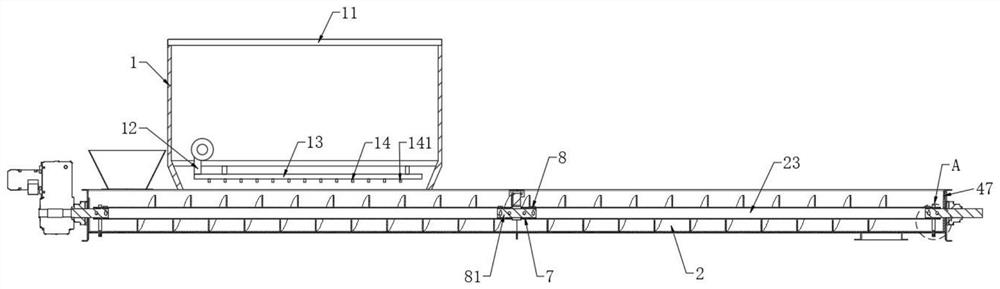

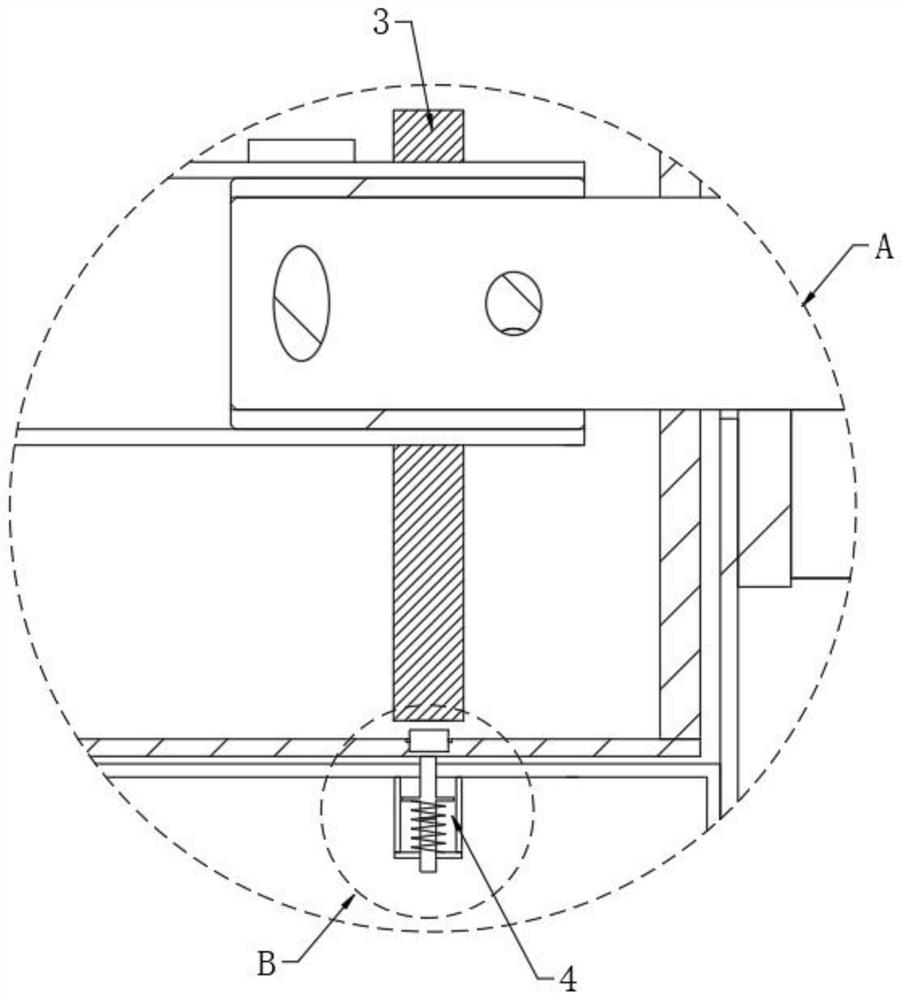

[0040] see Figure 1-6 , a preparation device for the production process of high-nitrogen type water-soluble fertilizer powder with a large number of elements, including a boron-zinc-silicon liquid storage tank 1, a display window for displaying the liquid level is arranged on the boron-zinc-silicon liquid liquid storage tank 1, and the boron-zinc-silicon liquid The boron-zinc-silicon liquid is stored in the liquid storage tank 1, and the lower part of the boron-zinc-silicon liquid liquid storage tank 1 is connected with the Jiaolong conveying mechanism 2, and the lower part of the boron-zinc-silicon liquid liquid storage tank 1 is fixedly welded on the top of the Jiaolong conveying mechanism 2;

[0041]The Jiaolong conveying mechanism 2 includes a conveying shell 21 installed at the bottom of the boron-zinc-silicon liquid storage tank 1, a feeding port 25 is provided under one side of the conveying case 21, and a feeding port is provided on the upper side of the conveying case...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com