NBR rubber plate with high laser engraving efficiency and preparation method thereof

A laser engraving and high-efficiency technology, applied in the field of rubber, can solve the problems of cumbersome molding process, environmental pollution, safety issues, etc., and achieve the effect of low engraving power, high vulcanization efficiency and fast speed

Pending Publication Date: 2022-04-29

TAICANG GUANLIAN POLYMERIC MATERIAL

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Compared with the traditional molded rubber sheet technology, laser engraved rubber sheet has several advantages: traditional molded rubber sheet, the molding process is cumbersome, and the etching process requires the use of corrosive chemicals, which not only brings safety problems, and pollute the environment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

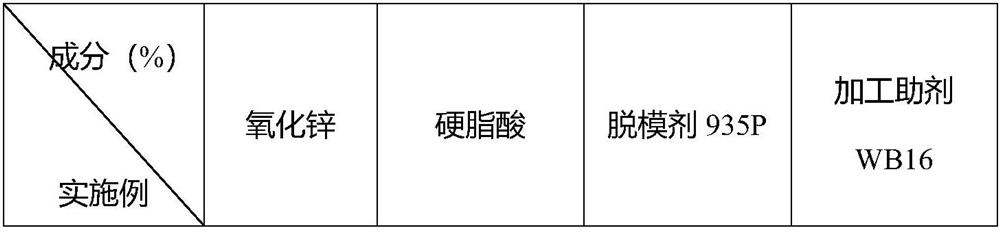

Embodiment 4

[0078] The four formulas of Examples all meet the requirements of product technical parameters, and the performance of the formula of Example 3 is the best. performance advantage. On the premise of meeting other physical performance requirements, the optimal cost-effective matching scheme can be reasonably selected according to the price changes of reinforcing fillers and softeners.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

The invention discloses an NBR rubber plate with high laser engraving efficiency. The NBR rubber plate is prepared from the following components in percentage by weight: 43 to 51 percent of nitrile rubber, 37.5 to 45.5 percent of a reinforcing filler, 0.5 to 2.0 percent of an anti-aging agent, 1.5 to 4.5 percent of a plasticizer, 2.5 to 6.5 percent of other compounding agents and 2.0 to 5.0 percent of a vulcanization accelerator. A sulfur system is adopted in the product, and the product has the advantages of being high in vulcanization speed, good in elasticity, low in compression set, small in power needed by laser engraving, high in speed, clear in engraved pattern, low in ashing degree of an engraved face, little in smoke in the engraving process, small in smell and the like.

Description

technical field [0001] The invention relates to rubber, in particular to an NBR rubber sheet with high laser engraving efficiency and a preparation method thereof. Background technique [0002] Rubber offset printing plates, rubber seals and rubber stamps can be manufactured using the laser engraving method. Using laser ablation technology, through laser irradiation, commonly used light sources include excimer lasers with 193, 248 or 308nm lasers, Nd-YAG lasers with a wavelength of 1.06um, and CO with a wavelength of 10.6um. 2 laser. In the process of laser irradiating the polymer, the absorbed radiation energy is converted into heat energy, and the local heat generation causes the polymer chain to crack and further generate low-molecular substances to be ablated, forming the desired pattern. [0003] Compared with the traditional molded rubber sheet technology, laser engraved rubber sheet has several advantages: traditional molded rubber sheet, the molding process is cumb...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more IPC IPC(8): C08L9/02C08L67/00C08K3/04C08K7/26C08K3/22C08K5/09

CPCC08L9/02C08K2003/2296C08L2201/08C08L67/00C08K3/04C08K7/26C08K3/22C08K5/09

Inventor 张子阳井垒周国荣苏怀生

Owner TAICANG GUANLIAN POLYMERIC MATERIAL

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap