Magnesium alloy plate and strip rolling emulsion and preparation method thereof

A technology for strip rolling and magnesium alloy plate, applied in lubricating composition, petroleum industry, etc., can solve problems such as energy waste, sticking of rolling pieces, and unstable rolling temperature, and achieve good plate surface cleanliness and reduced The effect of production cost and reduction of rolling energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

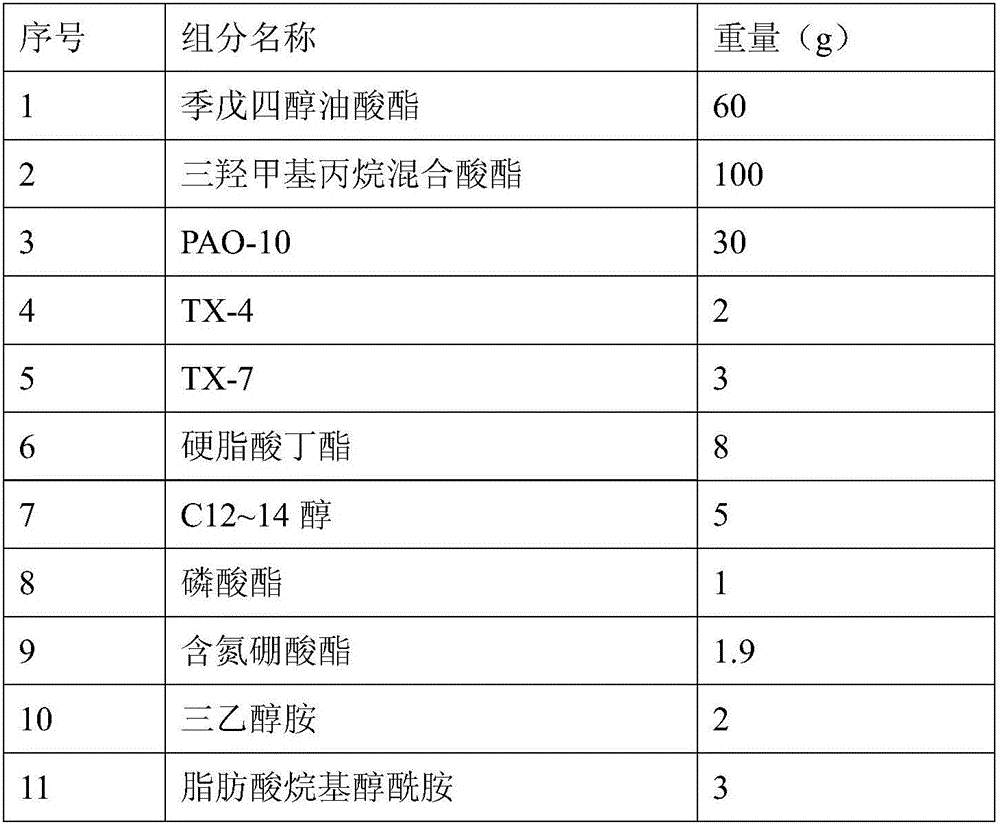

[0020] Embodiment 1 formula sees the following table:

[0021]

[0022]

[0023] Prepare the magnesium alloy plate and strip rolling emulsion according to the weight formula of each component in the above table. Butyl stearate (8g), C12-14 alcohol (5g), phosphoric acid ester (1g), nitrogen-containing borate (1.9g), triethanolamine (2g), fatty acid alkyl alcohol amide (3g), benzene Hydroxylated naphthylamine (2g) was added into the ultrasonic disperser sequentially, and ultrasonicated at a frequency of 25KHz for 25 minutes to make the four additives mix evenly. Then the mixed additives of pentaerythritol oleate (60g), trimethylolpropane mixed ester (100g), PAO-10 (30g) and above-mentioned oily agent, extreme pressure agent, rust inhibitor, antioxidant are added to reactor In the process, heat and stir to 85°C at a rotation speed of 140r / min. The constant temperature stirring time is 25 minutes, then cool to 45°C and keep for 10 minutes; after stirring, add emulsified sil...

Embodiment 2

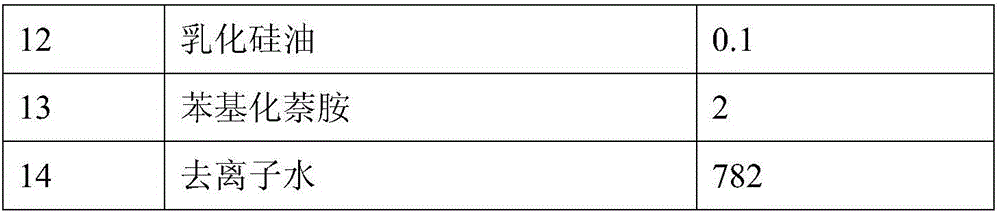

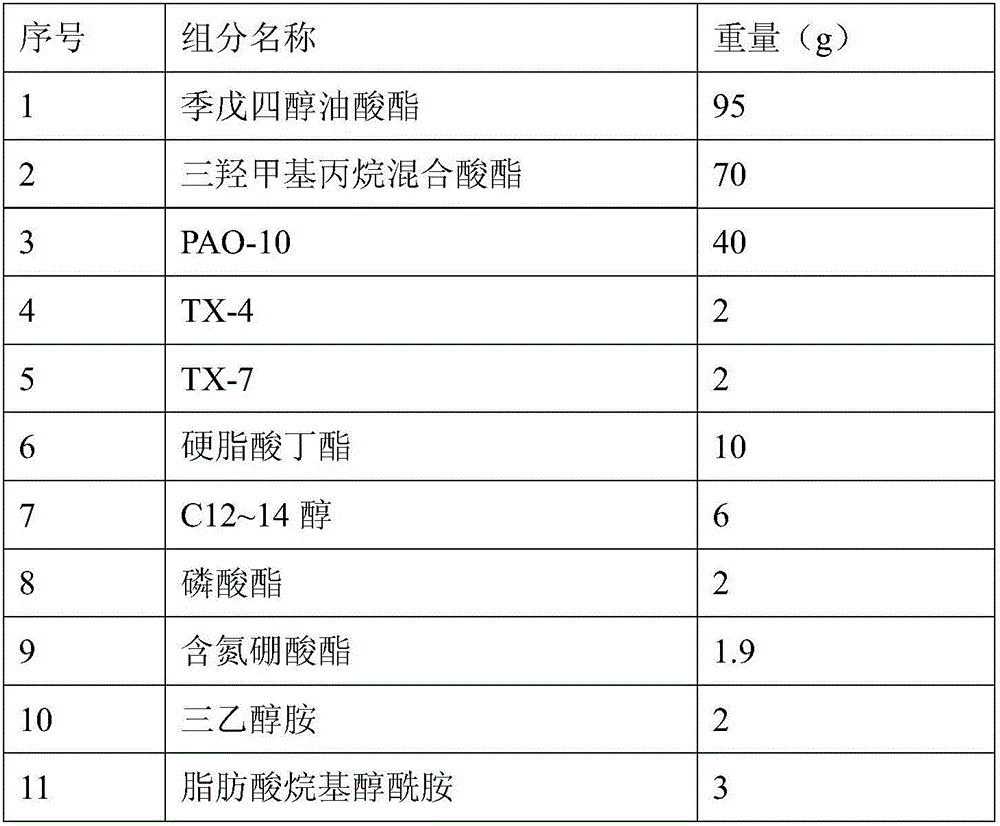

[0025] Embodiment 2 formula sees the following table:

[0026]

[0027]

[0028] Prepare the magnesium alloy plate and strip rolling emulsion according to the weight formula of each component in the above table. Butyl stearate (8g), C12-14 alcohol (5g), phosphoric acid ester (1g), nitrogen-containing borate (1.9g), triethanolamine (2g), fatty acid alkyl alcohol amide (3g), benzene Hydroxylated naphthylamine (2g) was added into the ultrasonic disperser sequentially, and ultrasonicated at a frequency of 25KHz for 25 minutes to make the four additives mix evenly. Then the mixed additives of pentaerythritol oleate (60g), trimethylolpropane mixed ester (100g), PAO-10 (30g) and above-mentioned oily agent, extreme pressure agent, rust inhibitor, antioxidant are added to reactor In the process, heat and stir to 85°C at a rotation speed of 140r / min. The constant temperature stirring time is 25 minutes, then cool to 45°C and keep for 10 minutes; after stirring, add emulsified sil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com