Pickling method for producing bone gelatin

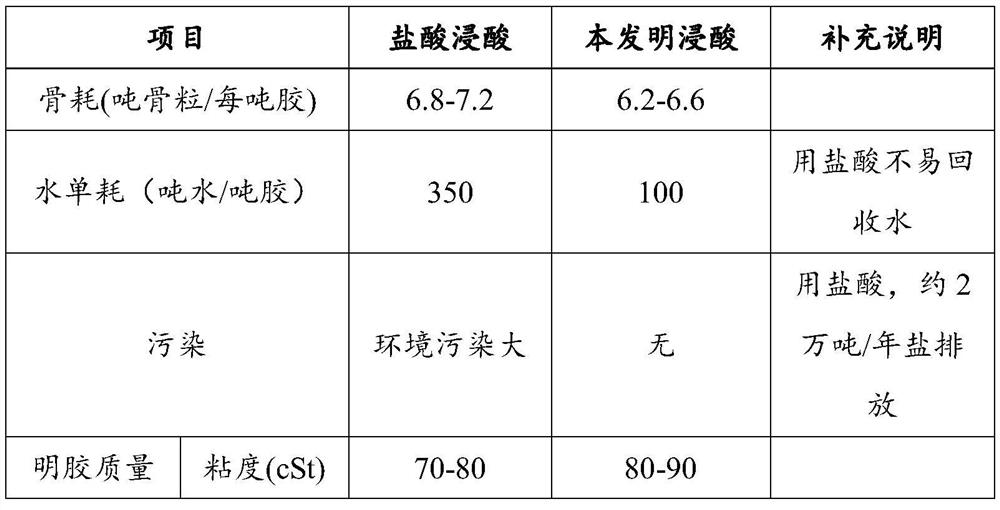

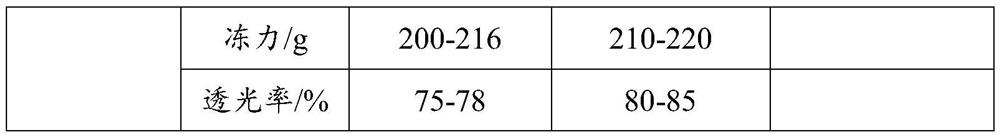

A technology of bone gelatin and pickling, applied in the preparation of animal glue or gelatin, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of difficult control of gelatin yield, equipment, pipeline corrosion, product quality impact, etc., to achieve reduction Waste of water resources, improve quality, achieve the effect of recycling and reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This example provides a pickling method in the production of bone gelatin, which uses bone particles commonly used in existing industrial production, which are degreased and then used for pickling.

[0029] In this embodiment, the phosphoric acid used is 85% food-grade concentrated phosphoric acid by mass percentage, which is used after being prepared into 8.5% dilute phosphoric acid, and the equivalent used is the same as that used for pickling with hydrochloric acid.

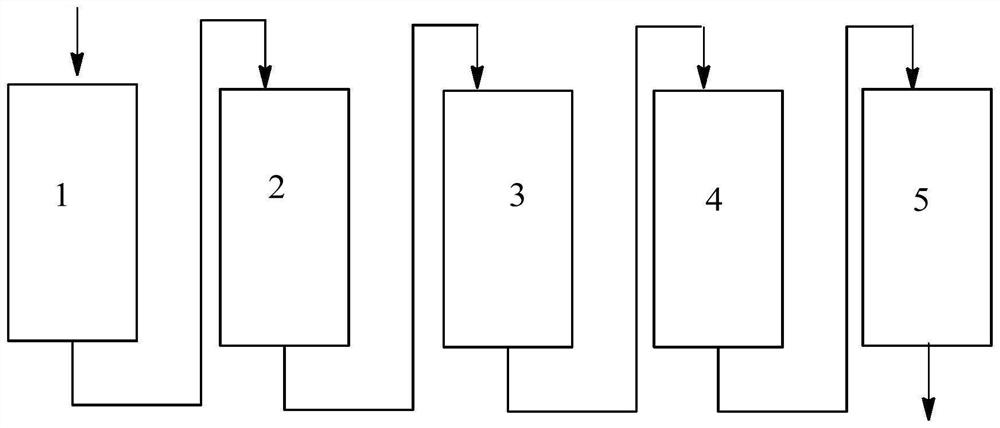

[0030] See the pickling device used figure 1 As shown, including fresh acid tank 1, first-level hypo-acid tank 2, secondary hypo-acid tank 3, third-level hypo-acid tank 4 and calcium water tank 5 connected in series, the prepared mass percentage concentration is 8.5 % of fresh phosphoric acid is added from the top of the new acid tank 1, the acid in the new acid tank 1 enters the first-level secondary acid tank 2 through the bottom of the new acid tank 1, and then through the top of the first-level seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com