Calculation method for fuel distribution in sintered granulated pellets

A calculation method and fuel distribution technology, applied in the field of iron and steel metallurgy, can solve the problems of high consumption of manpower and material resources, poor adaptability, long experiment cycle, etc., and achieve the effect of simple efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

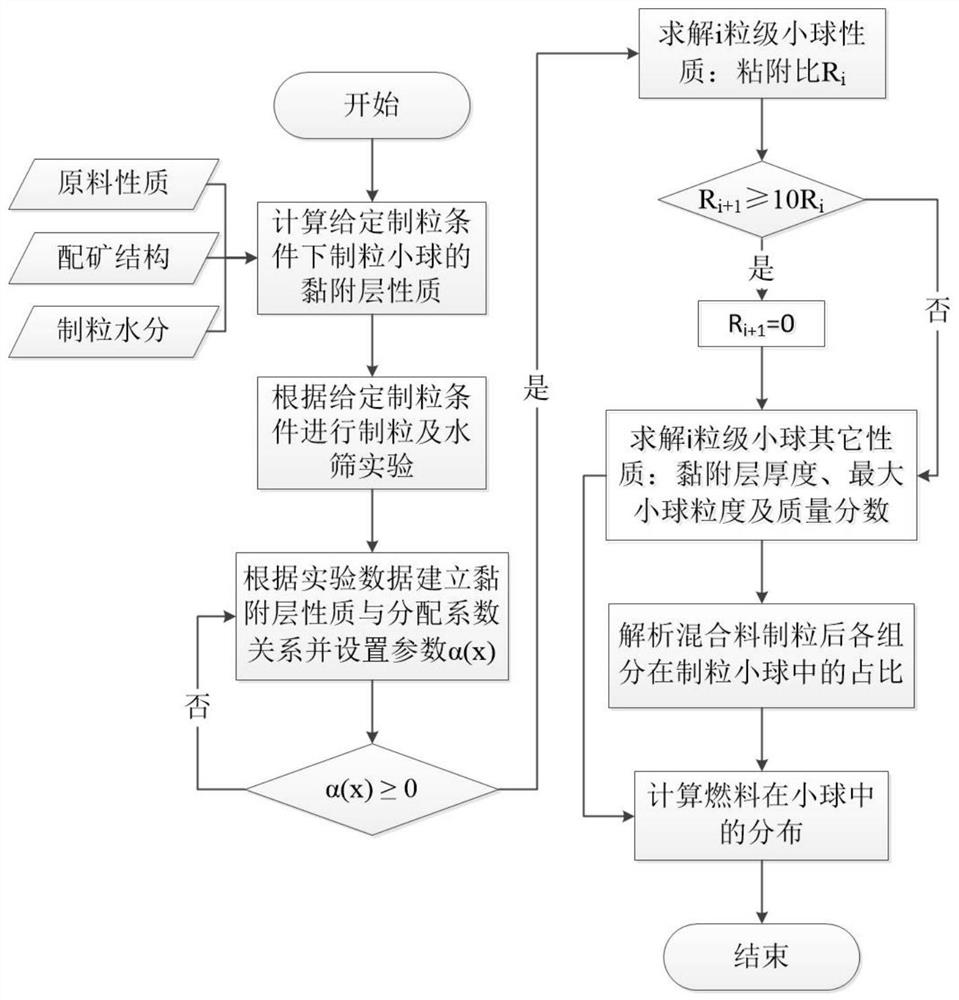

[0070] Depend on figure 1 As shown, a calculation method for fuel distribution in sintered pellets, including the following steps:

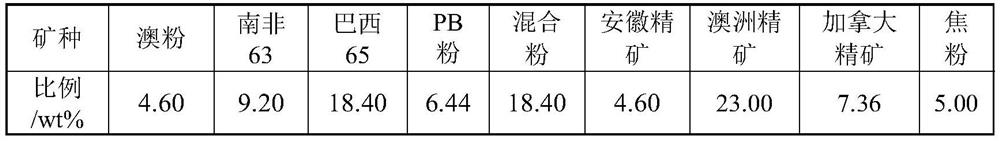

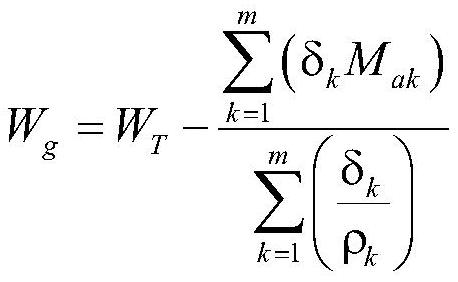

[0071] Step S1. Mainly consider the influence of raw material properties and granulation moisture on the distribution coefficient of each component. Through the granulation process, m kinds of sintered raw materials are mixed in a certain proportion. Based on the layer growth mechanism, the distribution coefficient α(x) is used to describe The probability that each component acts as a core particle and the -0.5mm particle in the raw material is considered to be the cohesive layer of the granulation pellet. When the granulation moisture is given, the relationship between the average pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com