Box-type after-treatment mixer and engine applying same

A mixer and box-type technology, which is applied to machines/engines, engine components, combustion engines, etc., can solve problems such as weakening engine output power and affecting combustion efficiency, improving emission consistency, improving mixing uniformity, and ensuring airflow. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

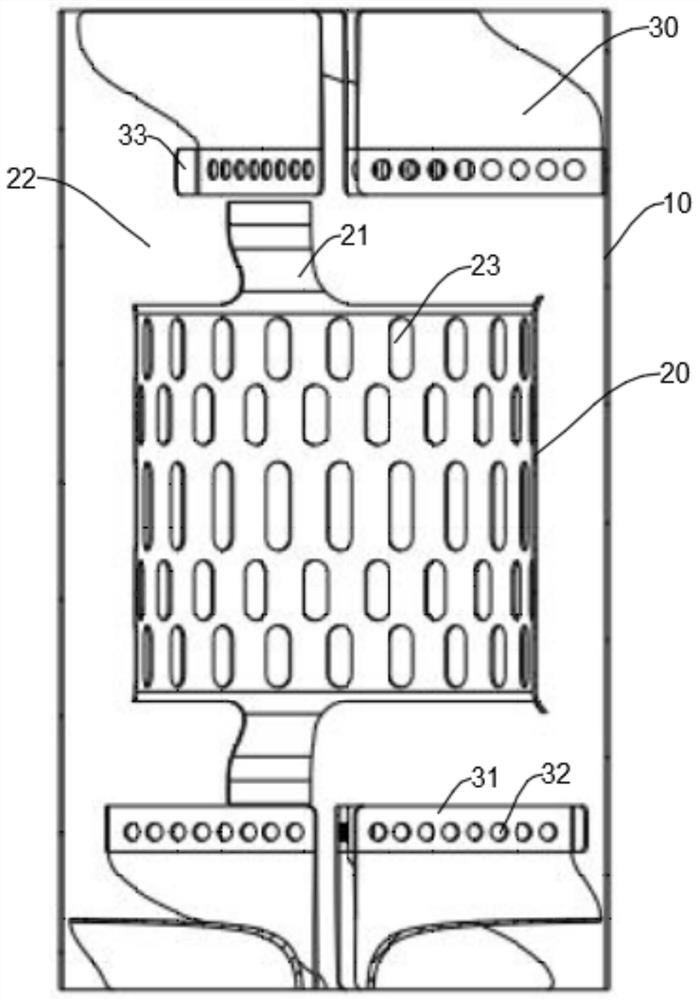

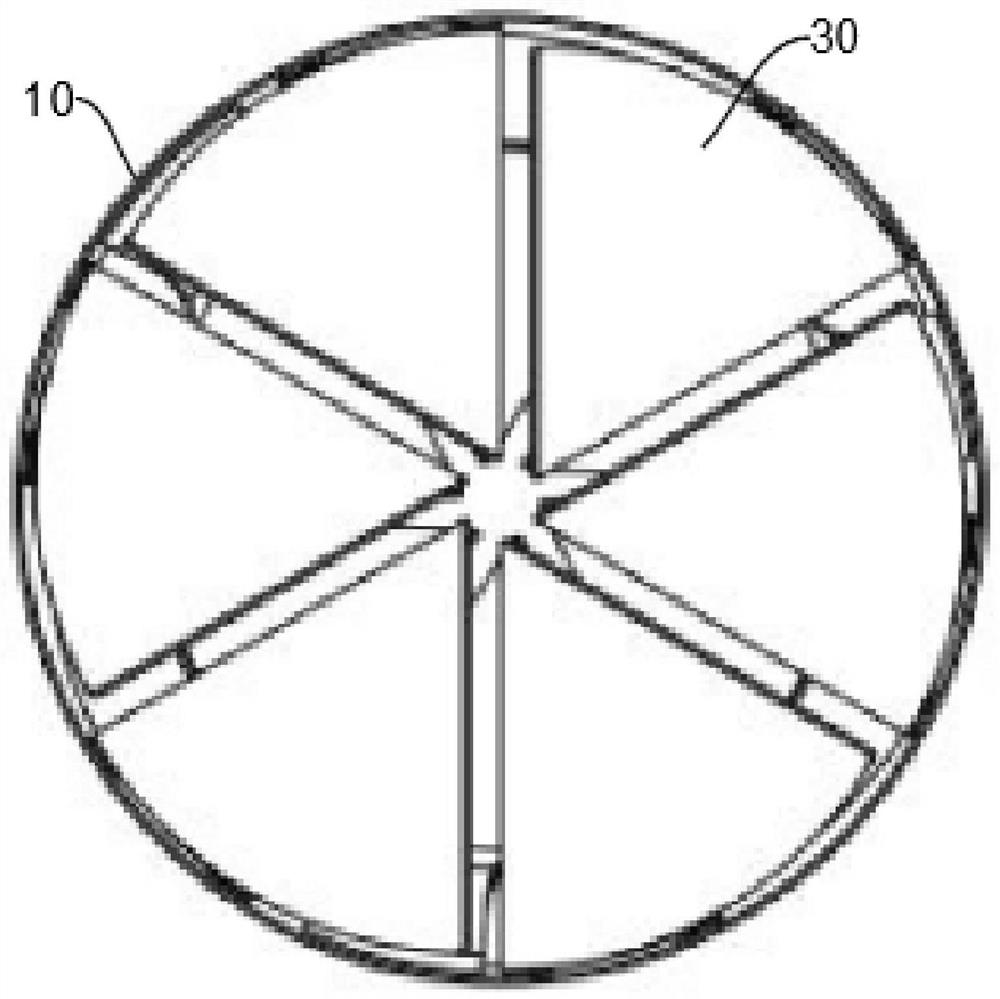

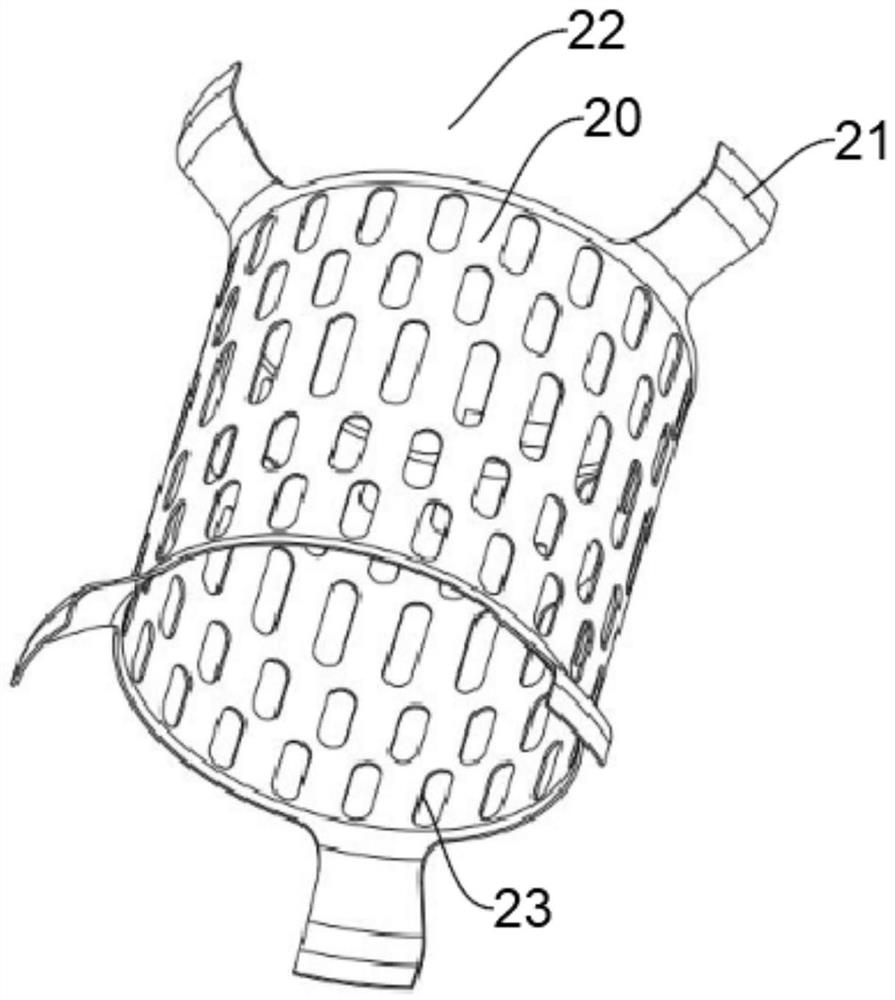

[0040] Such as figure 1 , figure 2 As shown, a box-type post-treatment mixer disclosed in this embodiment includes an outer tube 10, a mixing hole tube 20 arranged inside the outer layer tube 10, and multiple holes arranged at the front end and the rear end of the mixing hole tube 20 along the airflow direction. A set of swirl structures, each set of swirl structures includes a plurality of swirl fan blades 30 independent of each other, and each swirl fan blade 30 is separated from each other at the center of rotation. Since the swirl fan blade 30 is in the rotation process, the centrifugal force at the center is the lowest, which is the most prone to crystallization, while the edge of the swirl fan blade 30 is already in a separated state, so this embodiment uses the traditional post-processing mixer The integrated swirl fan is improved to a split swirl fan blade 30, by forming a separation at the center of each swirl fan blade 30, reducing the crystallization of urea at th...

Embodiment 2

[0044] The technical solution of this embodiment is basically the same as that of Embodiment 1, the only difference is that in this embodiment, each swirl structure is an axial swirl structure. The present application does not limit the specific structure of the swirling flow structure. In one embodiment, the swirling flow structure is an axial flow fan, and the aforementioned axial swirling flow structure is formed by the axial flow fan, and the mixed flow of exhaust gas and urea spray passes through After being guided by the axial flow fan, it flows along the axial direction of the outer tube 10 . However, the conventional vortex fan blade structure in the prior art can easily guide the airflow to the inner wall of the outer tube 10, so that the urea spray can easily crystallize on the inner wall of the outer tube 10, resulting in uneven mixing and blocking of the mixing channel by crystallization. In this embodiment, after optimizing the swirl structure to an axial swirl st...

Embodiment approach 1

[0050] In this embodiment, if Figure 4 As shown, the outer edge of each swirl fan blade 30 is provided with a first connecting portion 33 , and each swirl fan blade 30 is respectively fixed to the inner wall of the outer tube 10 through the first connecting portion 33 . Since each swirl fan blade 30 is provided independently, each swirl fan blade 30 needs to be respectively fixed on the inner wall of the outer tube 10 . In this embodiment, a first connecting portion 33 is provided on the outer edge of each swirling fan blade 30, and the first connecting portion 33 is integrally formed with the swirling fan blade 30, and the first connecting portion 33 is bent to be in line with the swirling fan. The outer arc surfaces of the blades 30 overlap, so that it is convenient to weld each swirl fan blade 30 on the inner wall of the outer tube 10 .

[0051] Preferably, the first connecting portion 33 can be formed by extending the deflector 31 in the foregoing embodiments. The defle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com