Charging device for presplitting blasting of peripheral holes of roadway

A technology of pre-split blasting and peripheral eye, applied in the field of blasting, can solve the problems of severe blasting vibration, increased explosive charge, damage to surrounding rock, etc., to achieve the effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical content of the present invention will be described in detail below in conjunction with the accompanying drawings.

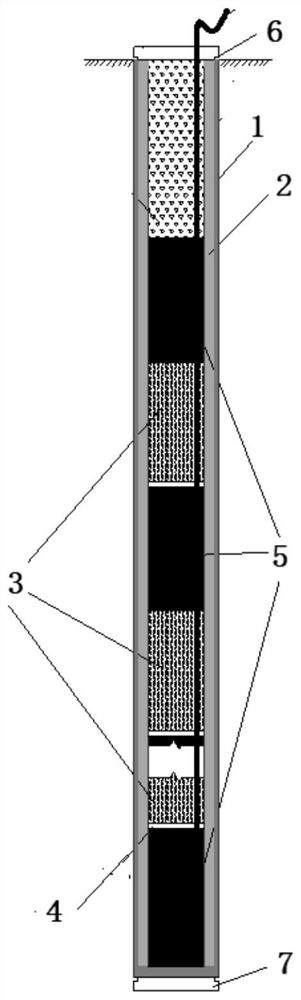

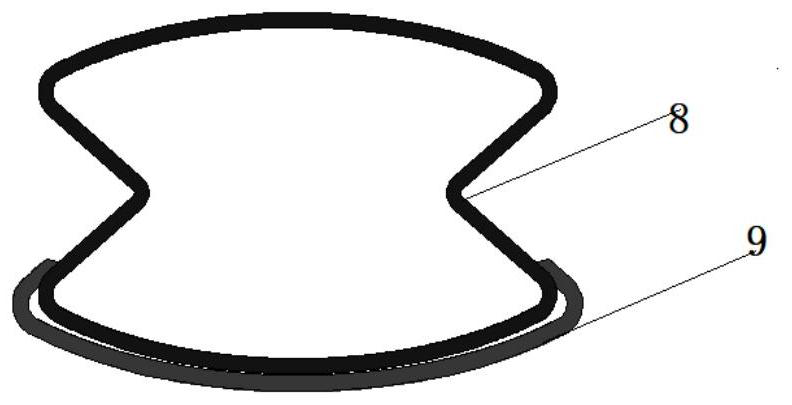

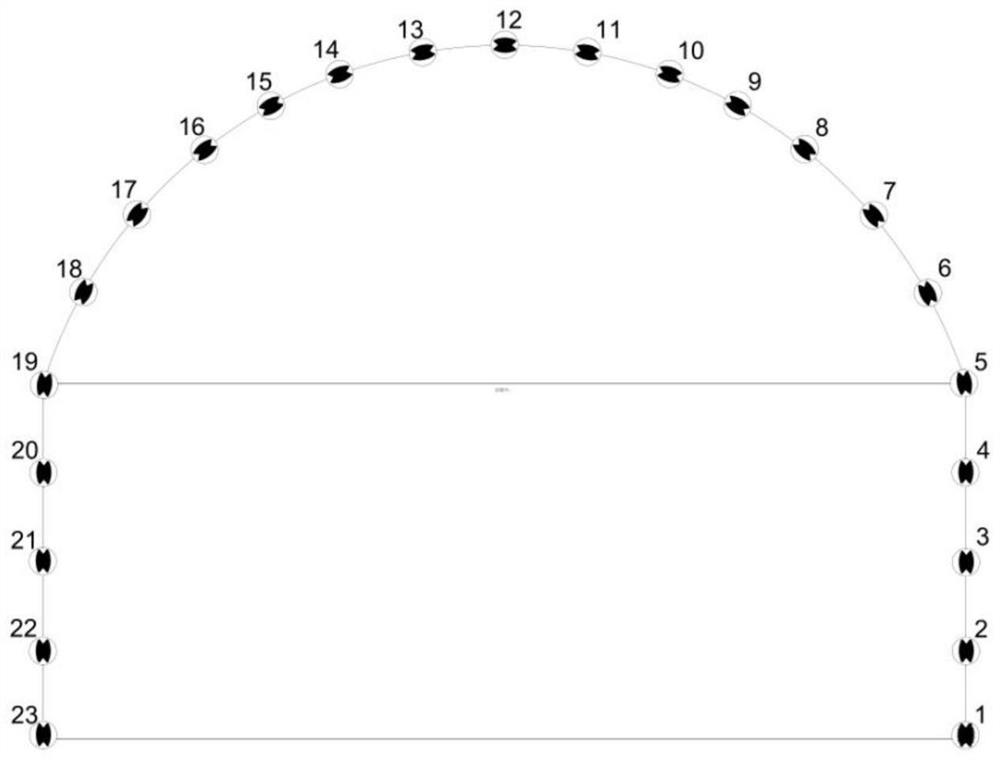

[0019] Such as figure 1 As shown, the peripheral eye of the present invention adopts a shock-isolation energy-concentrating tube 1 charge, the upper end of the shock-isolation energy-concentrating tube 1 is provided with a top cover plate 6, and the lower end is provided with a bottom cover plate 7, and the explosive package 5 in the shock-isolation energy-concentrating tube is separated from the air column 3 Design, the spacing distance of two explosive packs 5 generally can not be greater than the martyrdom distance of this kind of explosive in the borehole. Arrange a circle of pressurized water body medium 2 around the explosive package 5, and the high-pressure water-air mixture formed by the mixing of pressurized water around after the explosion can promote the further expansion of the explosive product along the explosive crack, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com